Cantek CFS100 Semi-Optimizing Defect Cut Off Saw

- Price

- $ 64,680

Have questions or need help choosing a machine?

Call us at 260-637-0054 or email sales@oaktreesupply.com

Made in Taiwan. Ships from the United States.

Our Easy Purchase Guarantee:

- In stock as of 2.25.26

- Freight included in price.*

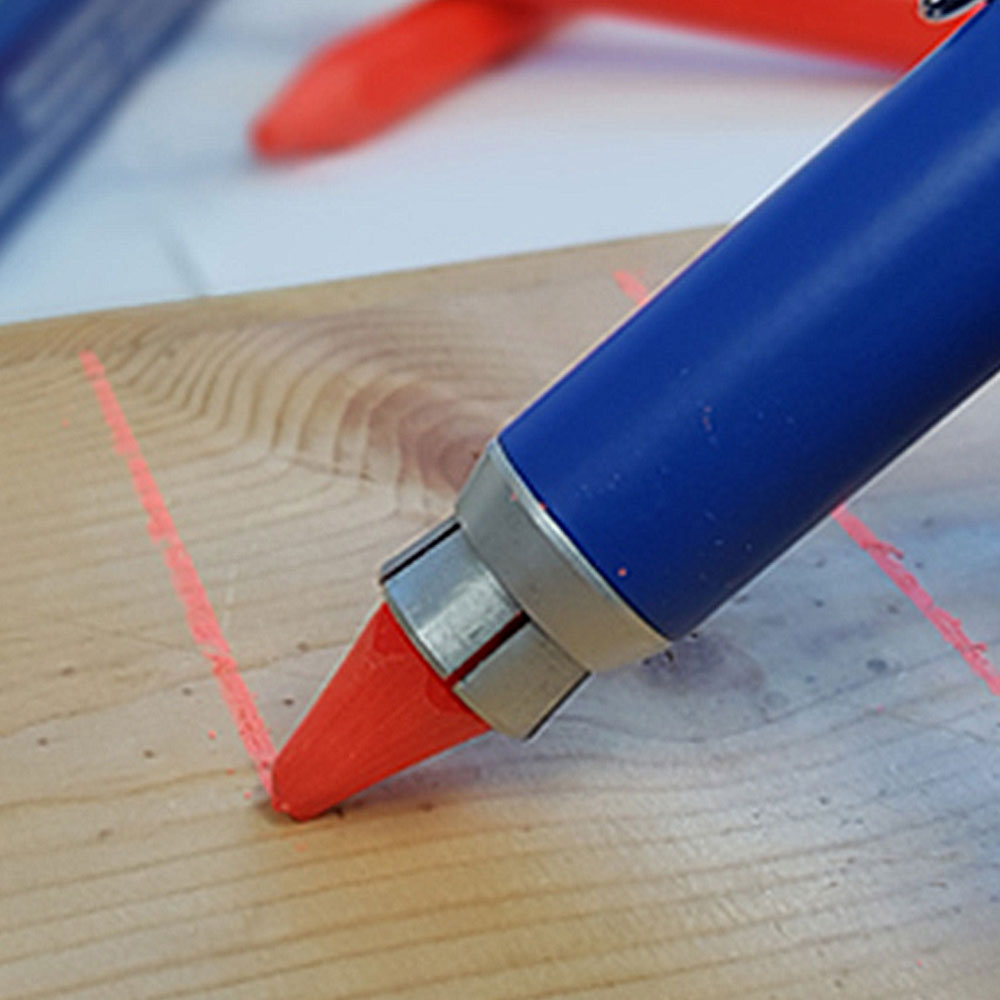

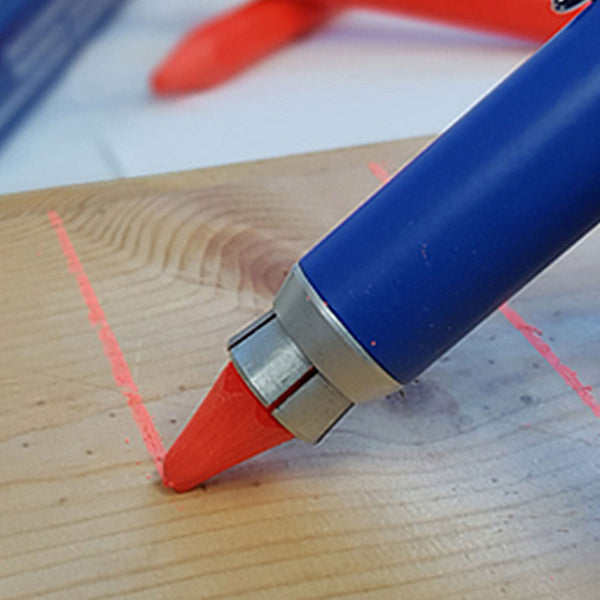

The Cantek CFS100 Automatic Defect Cutoff Chop Saw is the perfect upgrade from your manual cutoff saw with 3 to 5 times higher production output. It is designed to scan for defects in your material which are indicated by a florescent crayon mark. The saw will cut on the crayon mark allowing for fast defect removal.

Equipped with several cutting modes like fixed, sequential, and defect cutting modes the operator can select the program most suited to their needs. The powerful 10HP motor and 18” blade provide for effortless cutting from 11.8” (w) x 2.75” (t) or 5.9” (w) x 3.9” (t). An optional feature is available for cutting thin material down to 0.078” (2mm) which is ideal for lamellas for engineered flooring.

For flooring companies, the CFS100 can be combined in line with the EM12 End Matcher for a highly efficient defecting & end-matching solution. Pricing available upon request.

If you need a quote, we would be happy to provide one. Call 260-637-0054 or email sales@oaktreesupplies.com

Note: Cannot ship to Indiana, Ohio, Pennsylvania or California.

Features

- Ideal for the defect cutting wood mouldings, wood flooring, finger joint blocks, wood paneling, and more!

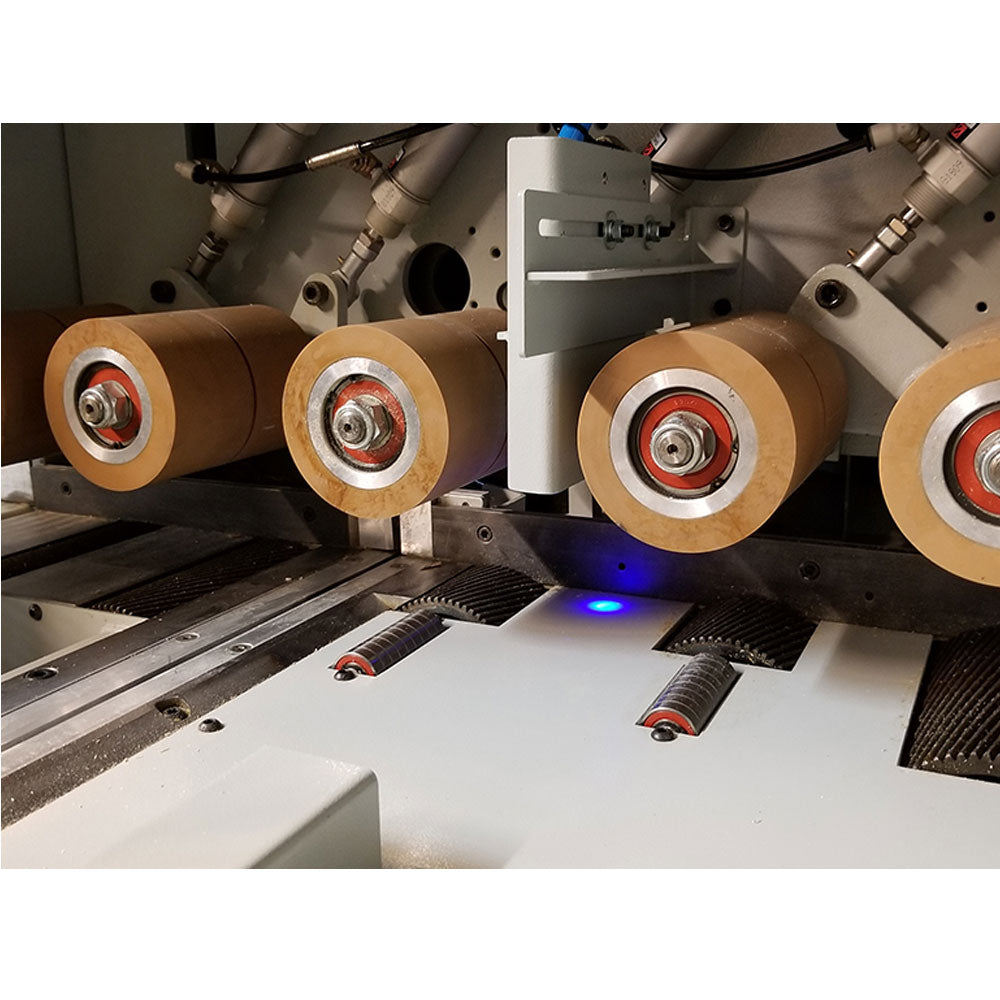

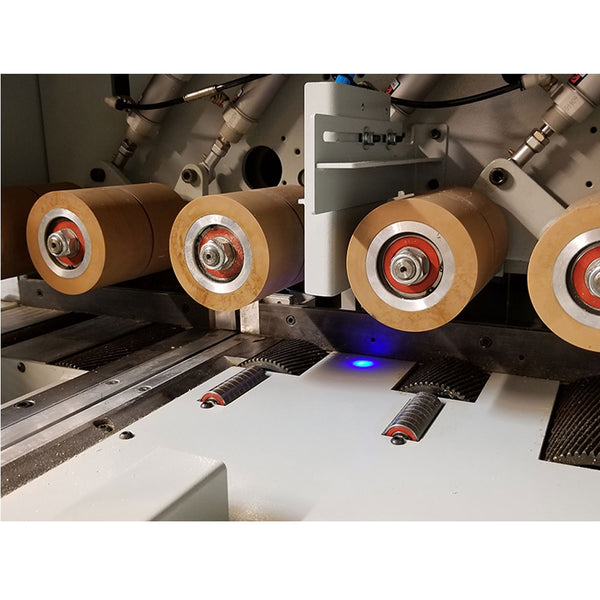

- Machine scans for defects marked with a florescent crayon allowing for high-speed defecting

- Provides 3 to 5 times higher production rate than manual cut-off saws

- 5% increase in material yield over manual cutting operations

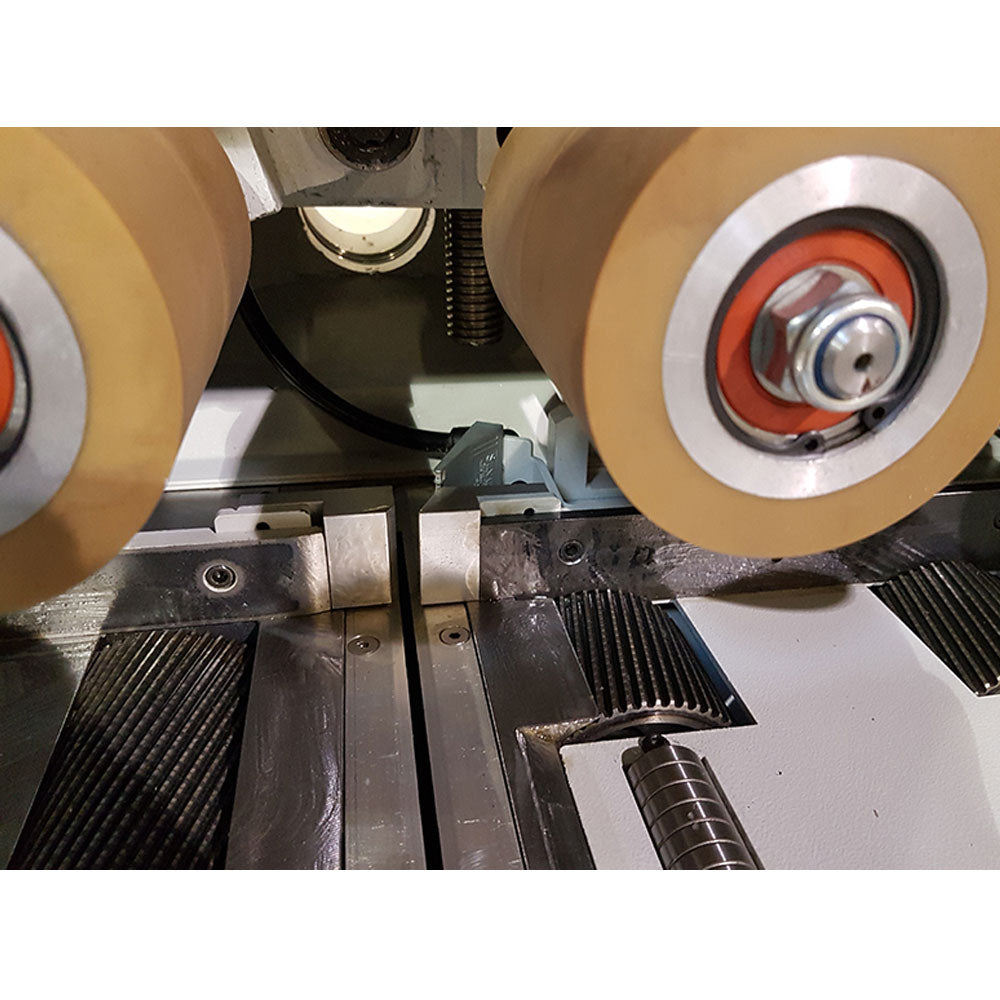

- +/- 1mm (0.0393”) accuracy

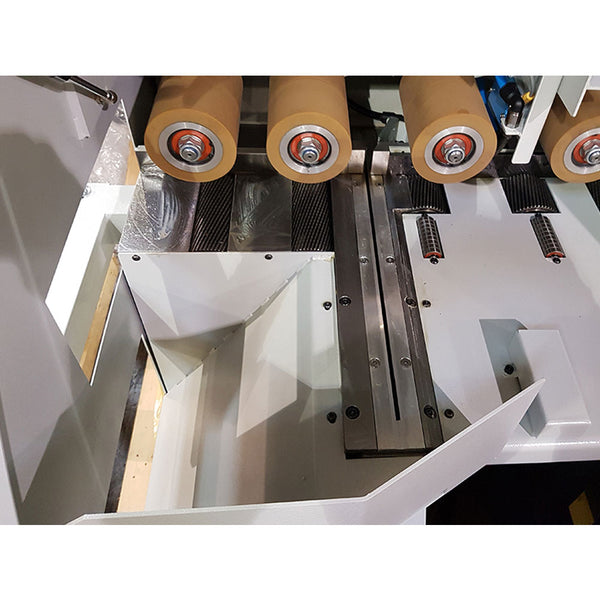

- Safe operation with automatic feeding and comprehensive safety guards

- Partial optimization with sequential and fixed part-cutting functions or simply cut-out defects

- User-friendly touchscreen control with on board synoptics, cutting counter, and menu-based cutting modes

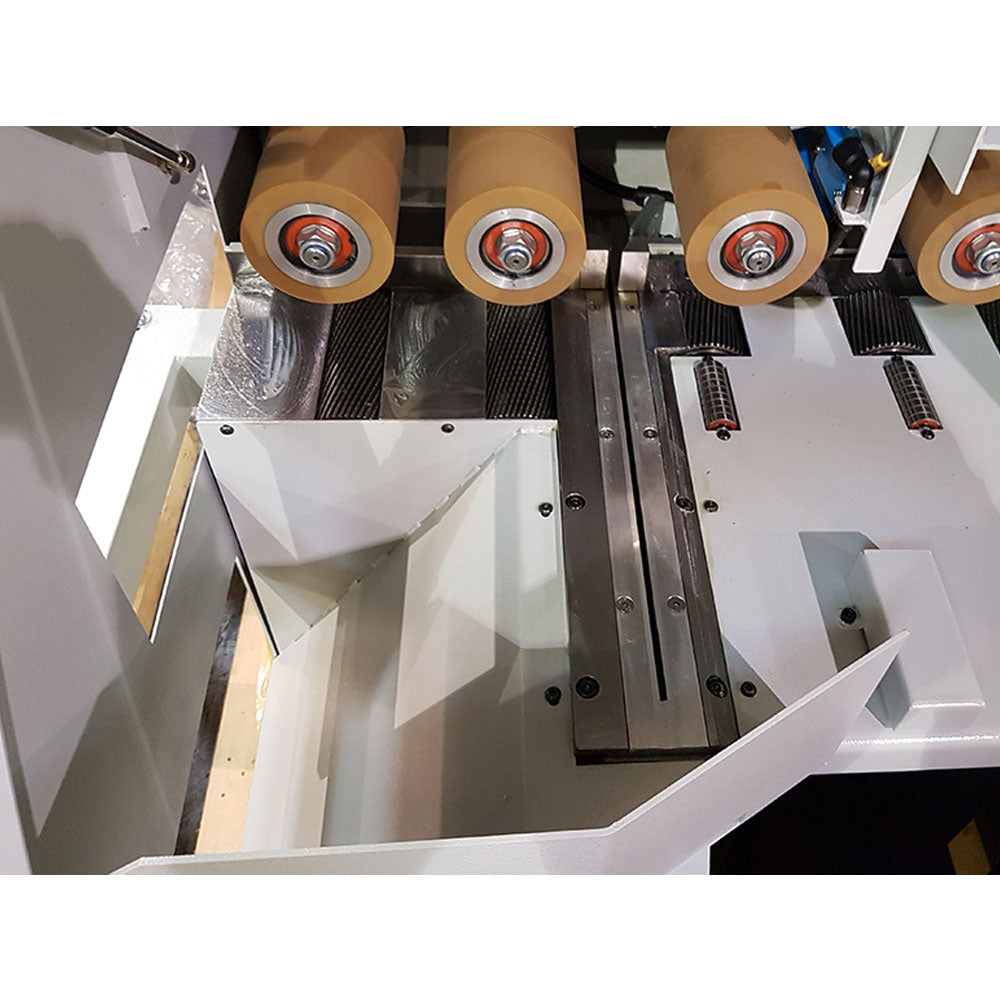

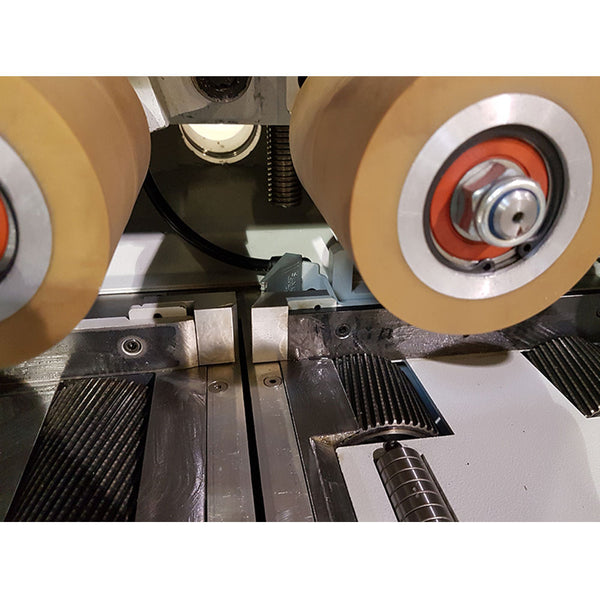

- Servo-driven feed motor for fast accurate motion and position control

- Compact design requires less space than manual cutting setups

- 18” diameter blade provides a large cross-cutting capacity

- Powerful 10HP motor running at 3200PRM

- Adjustable automatic trim of front and tail of the workpiece

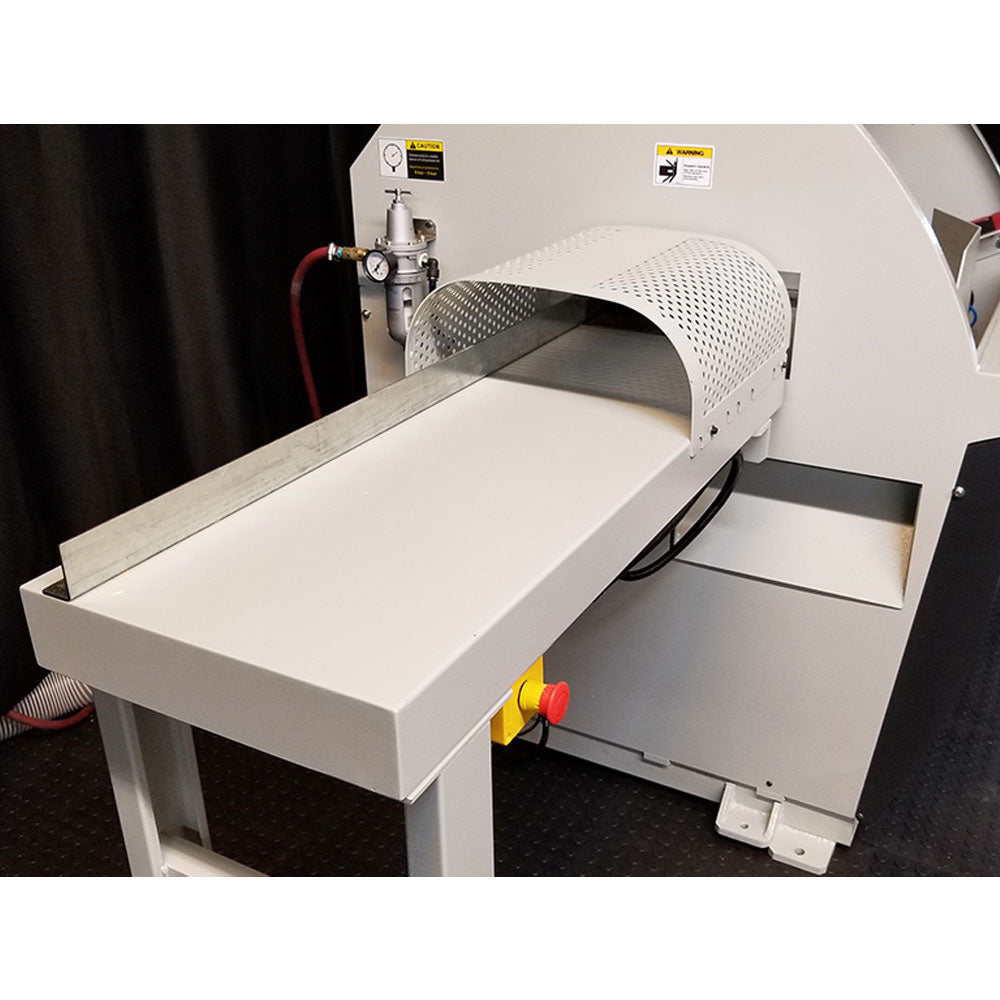

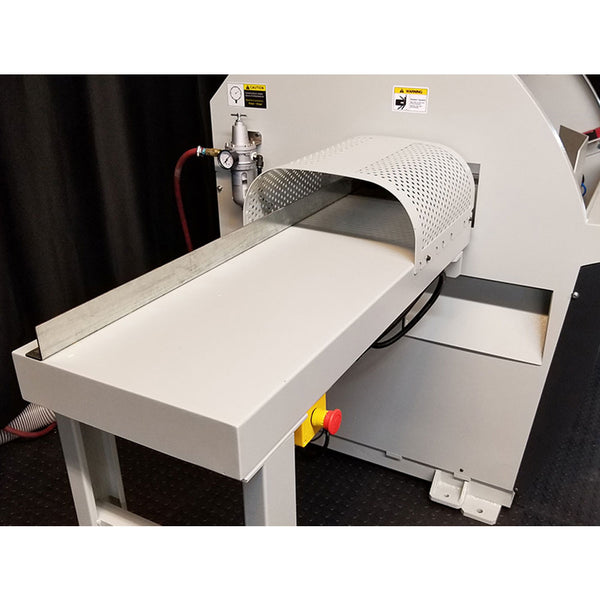

- Equipped with a 48” infeed table with idle steel rollers and back fence (additional length available upon request)

- 40″ (1 meter) long flat outfeed table (additional length available upon request)

- Defect blowing system combined with computerized logic control permits the blowing time and the length of defect to be set as desired

Specs

Saw Motor: 10HP

Saw Spindle Speed: 3,200 RPM

Feed Motor (Servo motor): 2.7HP (2Kw)

Max. feed speed: Variable to 262 ft/min (80 m/min)

Max. infeed weight: 44 lbs. (20 kgs)

Circular Saw Diameter: Ø 18” (455 mm)

Saw spindle diameter: 30mm

Minimum distance between marks: 0.787” (20mm)

Cutting Size – maximum: See the diagram of cutting range

Air pressure: for machine: 72~85 PSI (5~6 kg/cm2)

Air pressure: defect blowing system: 7~9 kg/cm2 (99.5~128 PSI)

Dust ports: 2 @ 4”

Electrics: 460/3/60 = 14 Full Load amps (Stock Machine)

Electrics: 230/3/60 = 28 Full Load amps (Factory order)

Electrics: 575/3/60 = 11 Full Load amps (Factory order)

Video

*Shipping

Please note: Items being shipped to extremely remote areas or areas with limited delivery access (such as islands only accessible by ferry) may incur additional shipping or freight fees. If your order requires any additional fees other than what is already included in the price, you will be contacted before those fees are applied and before your item ships. This is rare and will not apply to most orders.