Cantek EM12 Automatic Throughfeed End Matcher

- Price

- $ 60,165

Have questions or need help choosing a machine?

Call us at 260-637-0054 or email sales@oaktreesupply.com

Made in Taiwan. Ships from the United States.

Our Easy Purchase Guarantee:

- Please call for availability.

- Freight included in price.*

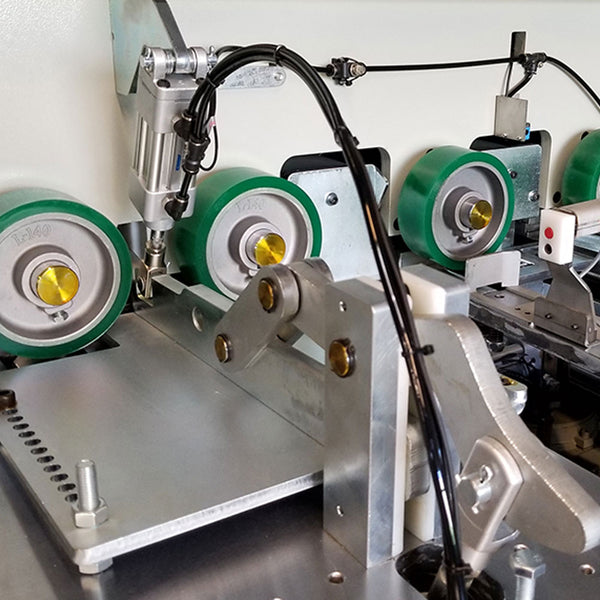

The Cantek EM12 End Matcher is specially designed for machining tongue and groove (with or without bevels) on hardwood flooring and wall/ceiling paneling up to 12” wide. Its compact design with a continuous through-feed system allows for maximum output in a small space.

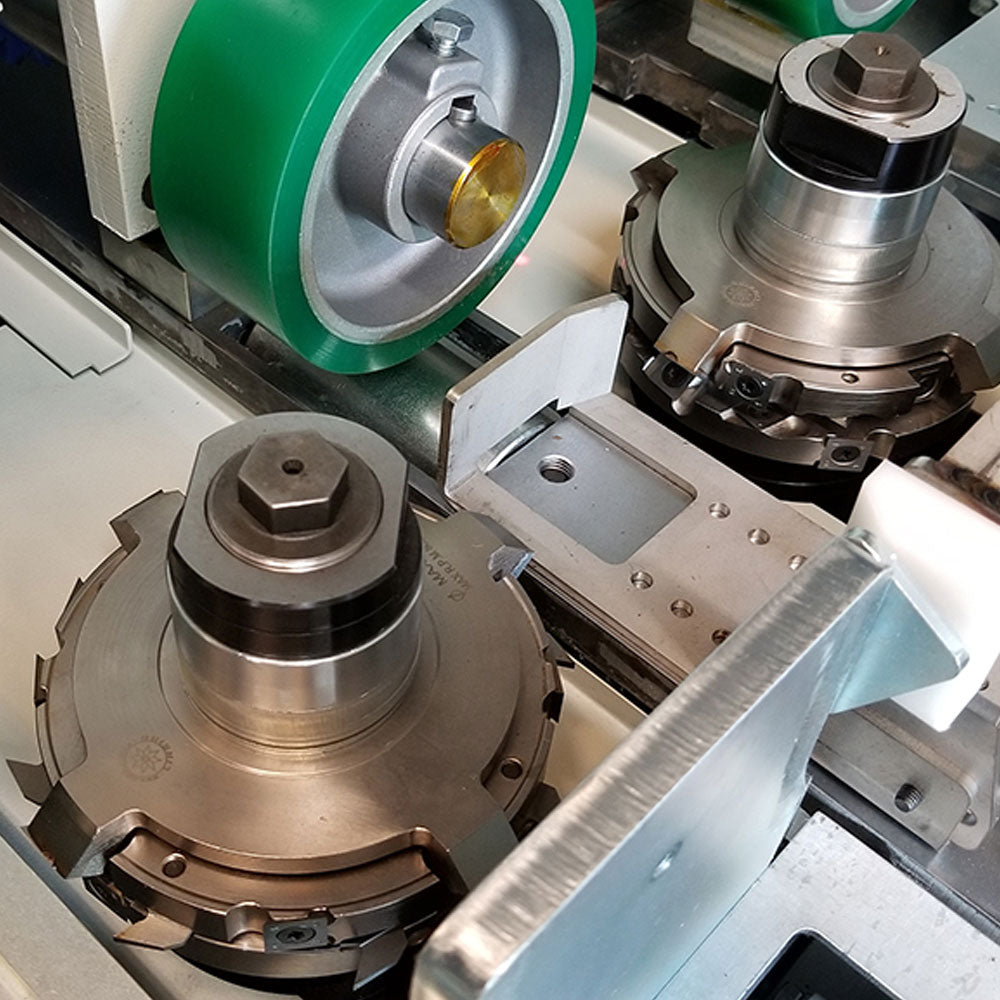

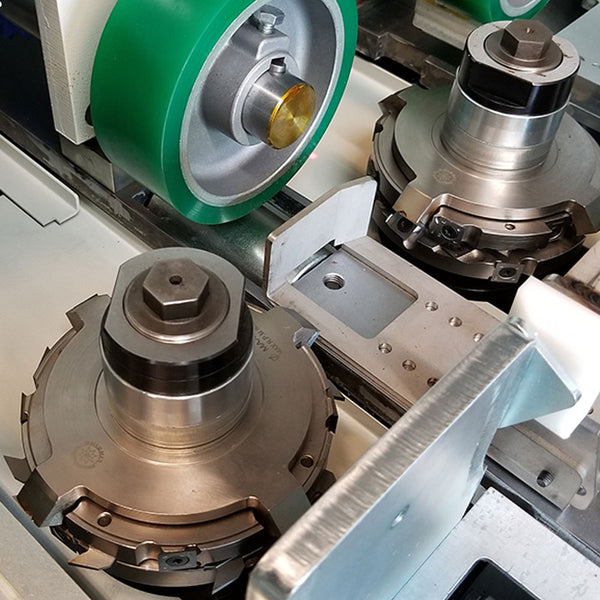

Equipped with a user-friendly touchscreen interface allow for simple operation with excellent performance and error diagnostics. The dual counter-rotating cutterheads produce both the tongue and groove simultaneously ensuring a perfect match. The anti-tear-out blocks and counter-rotation of the heads ensure optimum cut quality without chipping or blowout. The insert-style segmented cutterheads can be adjusted according to your desired tongue/groove thickness and can perform a micro-bevel or not.

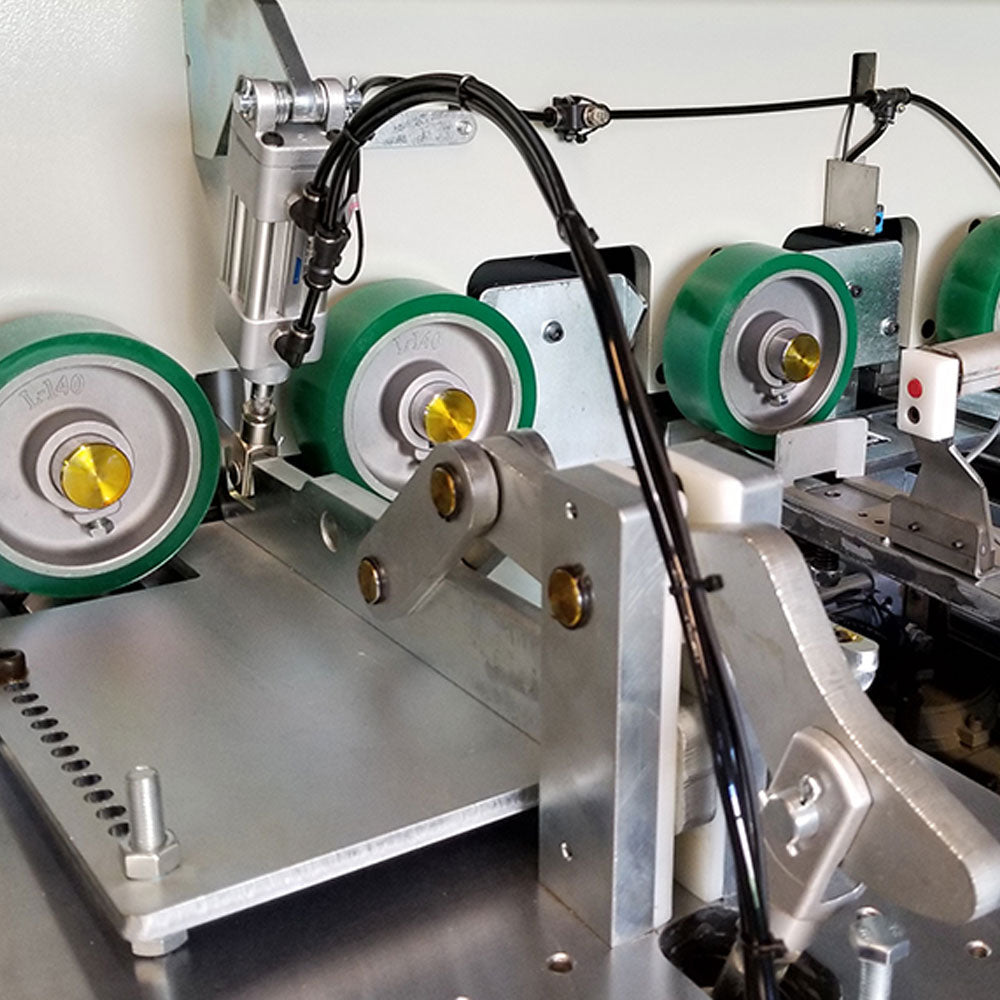

The variable speed infeed conveyor, variable feed speed, and variable cross-cutting speed allow the operator full control according to the type and size of material being run. The innovative clamps allow for simultaneous top and side clamping to ensure pieces are perfectly square for consistent end-matching results.

For added productivity, the EM12 End Matcher can be installed in line with our CFS100 Automatic Defect Cutoff Chop Saw to perform defecting and end matching in a single line. This greatly reduces the handling while increasing output with defect-free flooring or paneling.

If you need a quote, we would be happy to provide one. Call 260-637-0054 or email sales@oaktreesupplies.com

Note: Cannot ship to Indiana, Ohio, Pennsylvania or California.

Features

- 12″ Wide Continuous Through-Feed System – Handles Random Length Min. 12″ to Any Length

- Designed to produce end-match tongue & groove on hardwood flooring and paneling

- Also can be used for Finger Joint Cutting – if desired

- Can handle random lengths from 11” to an unlimited length

- Powered 10’ roller infeed conveyor and 8’ gravity outfeed conveyor (other lengths and options available to suit your requirement)

- The through-feed design allows for the tongue and groove to be cut simultaneously

- Counter-rotating cutter heads and anti-tear out blocks ensure a superior finish

- Carbide insert cutterhead set included

- Easy use touch screen control will also keep track of the total linear feet run as well as keep a piece count.

- Complete Safety and Noise Reduction Enclosure

- All Controls easily accessed from front of machine

- Variable speed through feed systems is controlled by frequency inverter

- Carbide Insert Type T & G Cutterheads – included Std – 1 set (extras optional)

Specs

Capacity

Width: 1.6″~12″

Thickness: 0.4″~1.38″

Min. Length: 12”

Max. Length: Unlimited

Feed

Feed Speed – max.: 295 FPM

Cutting Speed – approx. throughput: 77 FPM (Based on 6.5′ board)

Powered Infeed Table – Std.: 173″ (14.4’) long – longer optional

Outfeed Table – Std.: 86.6” (7.2’) long – longer optional

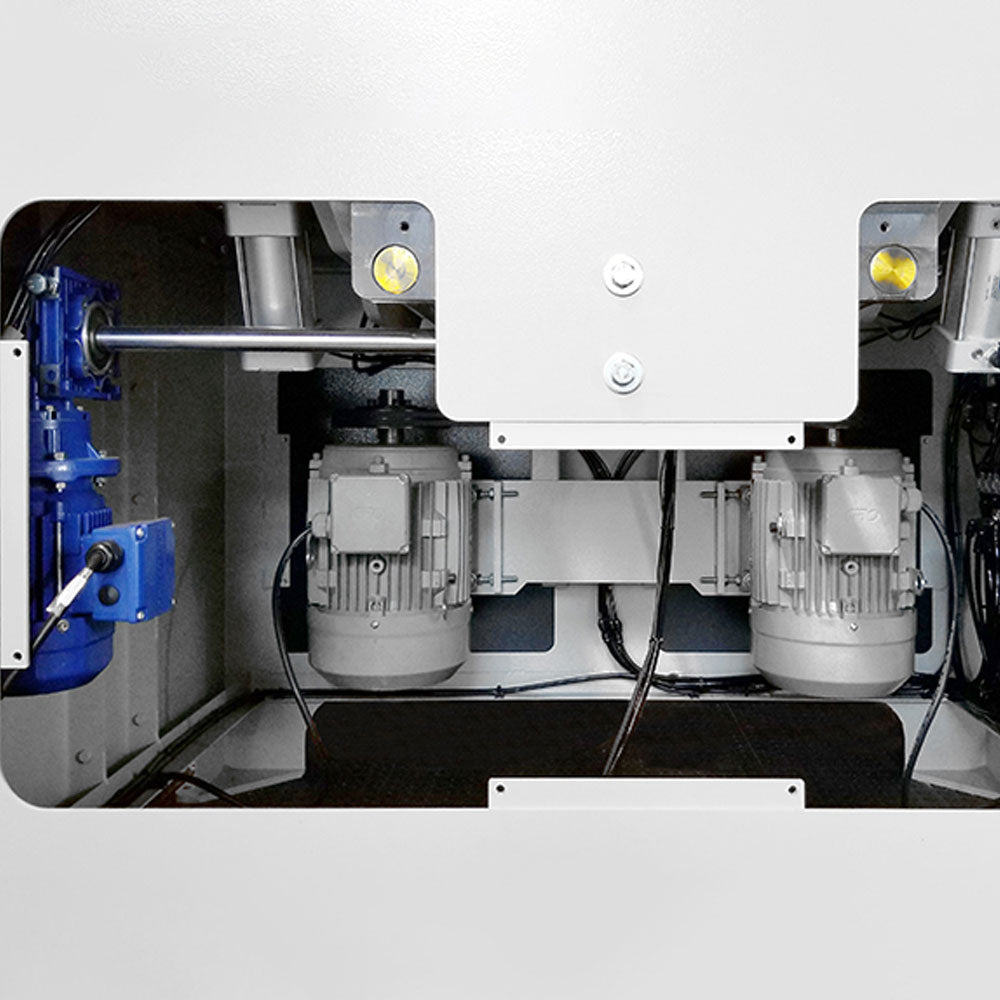

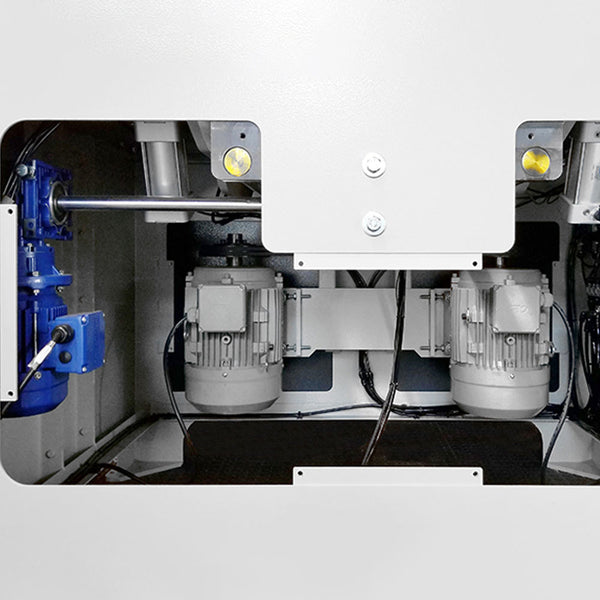

Motors

Cutterheads: 10Hp x 2

Feed System: 1hp

Cutter Drive: 1/2hp

Electrical

Power: 230, 460 or 575/3/60

Control Voltage: 24 VDC

Connected Load: 21.5HP

Full load amperage (FLA): 230/3/60 – 50.4 Amps 460/3/60 – 25.20 Amps

Clamping

Clamping: Top & Side

Other data

Spindle Dia.: 40 mm

Dust Collection Outlet: 6” diameter

Compressed Air Requirements: 85PSI – approx. 12 CFM

Machine Dimensions (L x W x H): 91” x 51.5″ x 63″

Machine Weight: 2,530 lbs.

Video

*Shipping

Please note: Items being shipped to extremely remote areas or areas with limited delivery access (such as islands only accessible by ferry) may incur additional shipping or freight fees. If your order requires any additional fees other than what is already included in the price, you will be contacted before those fees are applied and before your item ships. This is rare and will not apply to most orders.