SCM Startech CN K Compact CNC

- Price

- $ 13,375

Have questions or need help choosing a machine?

Call us at 260-637-0054 or email sales@oaktreesupply.com

Made in Italy. Ships from the United States.

- Freight included in price*

- Low stock as of 1.8.26**

- Machine configuration

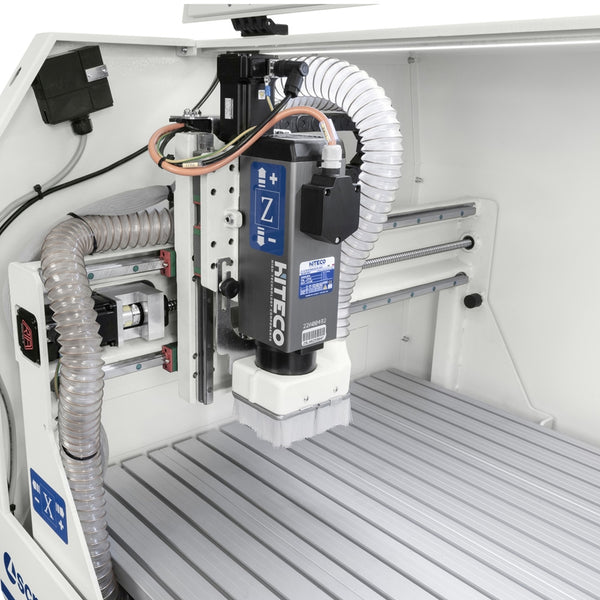

The Startech CN K from SCM is a 3-axis machining center designed for artisan woodworkers, training programs, and industrial prototyping teams. This cutting-edge CNC is equipped to handle a wide range of tasks, from milling and decorative work, to engraving, signboard creation, and even 3D model prototyping.

The Startech CN K is built for users who want professional results without the complexity, offering quick setup and an intuitive workflow that many operators can manage independently. Its fully enclosed cabin is complete with internal LED lighting; this sets a new safety standard, protecting the operator while keeping dust and debris contained for a cleaner workspace.

Unlike other machines in its class, the CN K features a powerful 2.2 kW electro-spindle with an R25 tool chuck, a specification typically found on higher-end models. Programming is straightforward thanks to its open, user-friendly interface, which can import G-code from virtually any CAD/CAM software.

Optional Installation & Training

When purchased, installation will be performed by an SCM factory-trained service technician or certified dealer technician. Installation is defined as assembling the machine to its "ready-to-run" state; it does not include floor/masonry work or running electrical, pneumatic, or dust extraction services. Training will be conducted on site by the technician after installation is completed.

Warranty

SCM warrants that every machine is free of defects in workmanship and materials for a period of one (1) year beginning on the date the machinery is accepted by the customer. Belts, bearings, and common electrical parts carry a six-month warranty. This warranty does not include wearable items or maintenance required in the ordinary course of operation.

Features

- Maximum Safety: Integral cabin that ensures protection for the operator and keeps the surrounding environment clean.

- Unique in its Category: The machine has a powerful 2.4 kW electro-spindle with R25 shank, generally used on higher-end machines.

- Easy Programming: "Open" virtual human-machine interface capable of importing G-code from any type of CAD / CAM software (it is advisable to verify with the software supplier that the cad/cam provides a G-code that can be read from the interface).

Specs

Work table dimensions: 1,170 x 760mm (46” x 30”)

“T” grooves dimensions: 13.5 x 7mm (0.5” x 0.25”) - 8.5mm opening for passage of M8 screw or nut

Axes

X-Y-Z strokes: 915 – 610 – 176mm (36” – 24” – 6.9”)

Z work piece clearance: 160mm (6.3”)

X-Y-Z maximum axis stroke: 5 – 5 – 2.5 m/min (16 -16 – 8 ft/min)

Min. distance of the spindle ring from the work table: 10mm (0.37”)

Axes positioning precision: ±0.05mm (±0.002”)

Electrospindle

Hiteco electro spindle motor power: 2.4kW - S6 at 300Hz

Max. rotating speed: 24,000 RPM

Tool chuck: R25

Tools

Max. tool holder diameter: 16mm (0.62”)

Max. tool diameter: 60 mm (2.31”)

Installation requirements

*Electrical requirements: 230 V – 60 Hz - Single-phase – 16 A

Nominal extraction air consumption: 115 m3/h (67 CFM)

Exhaust air speed: 20 m/s (66 ft/s)

Exhaust outlet diameter: 40 mm (1.56”)

Compressed air consumption

(only with pneumatic suction cups option): 120 Nl/min

Pneumatic system operating pressure

(only with pneumatic suction cups option): 6.5 bar

*Subject to change; must be verified prior to installation.

Includes

- 230V - 60 Hz single-phase power supply

- Integral protection cabin with plexiglass front door

- NC movement with 3 interpolating axes

- Ethernet port for user PC connection (PC not included)

- 2,4 kW S6 Hiteco electrospindle (18000/24000 rpm) with R25 attachment

- Work table with "T" grooves (passage of M8 screw or nut)

- Internal LED lighting

- HICAM2 virtual human-machine (HMI) interface

- Machine support base with wheels and adjustable feet

- (5) Pneumatic suction cups

- Tool height detection sensor

Optional Accessories

NOTE: The following accessories are optional and not included with the machine. They can be purchased at any time, but you can also take advantage of Accessory Bundle Pricing (applicable only at the time of machine purchase). Call us at (260) 637-0054 for more information and to place your order!

4th Interpolating Axis

-Attaches to the work table. Designed for lathe processing.

Vectric VCarve Pro Software

-Produce complex 2D profiled patterns, pocket/drill/inlay toolpaths, create designs with v-carving textures, and import Vectric 3D clipart or single model files. Also gives you unlimited job and toolpath size and true shape nesting.

Video

*Shipping

Please note: Items being shipped to extremely remote areas or areas with limited delivery access (such as islands only accessible by ferry) may incur additional shipping or freight fees. If your order requires any additional fees other than what is already included in the price, you will be contacted before those fees are applied and before your item ships. This is rare and will not apply to most orders.

**Machinery Availability Key

Availability statuses found above the product description reflect where a machine is in the supply chain at the time of listing. Use the key below to help determine the lead time for this machine.

In stock for immediate shipment: The machine is in OakTree Supply's warehouse and is ready to ship.

In stock as of [date] / Low stock as of [date]: The machine is in the manufacturer’s U.S. warehouse and was available as of the last update we received. Estimated to ship in 3-5 business days. If low stock, please call us before ordering to confirm current availability.

Estimated to ship [date]: The machine is not yet in our warehouse or the manufacturer’s warehouse. The date shown is an estimate based on current production and shipping timelines and may change due to manufacturing schedules, import processing, or freight transit.

Dates listed as “estimated” are not guaranteed and may change. OakTree Supply is not responsible for delays in transit to or from our facility.