SCM Class TF 130 Fixed Spindle Shaper

- Sale price

- $ 13,875

- List price

- $ 14,875

Have questions or need help choosing a machine?

Call us at 260-637-0054 or email sales@oaktreesupply.com

Made in Italy. Ships from the United States.

- Freight included in price*

- In stock for immediate shipment!**

- Only one machine available at this price

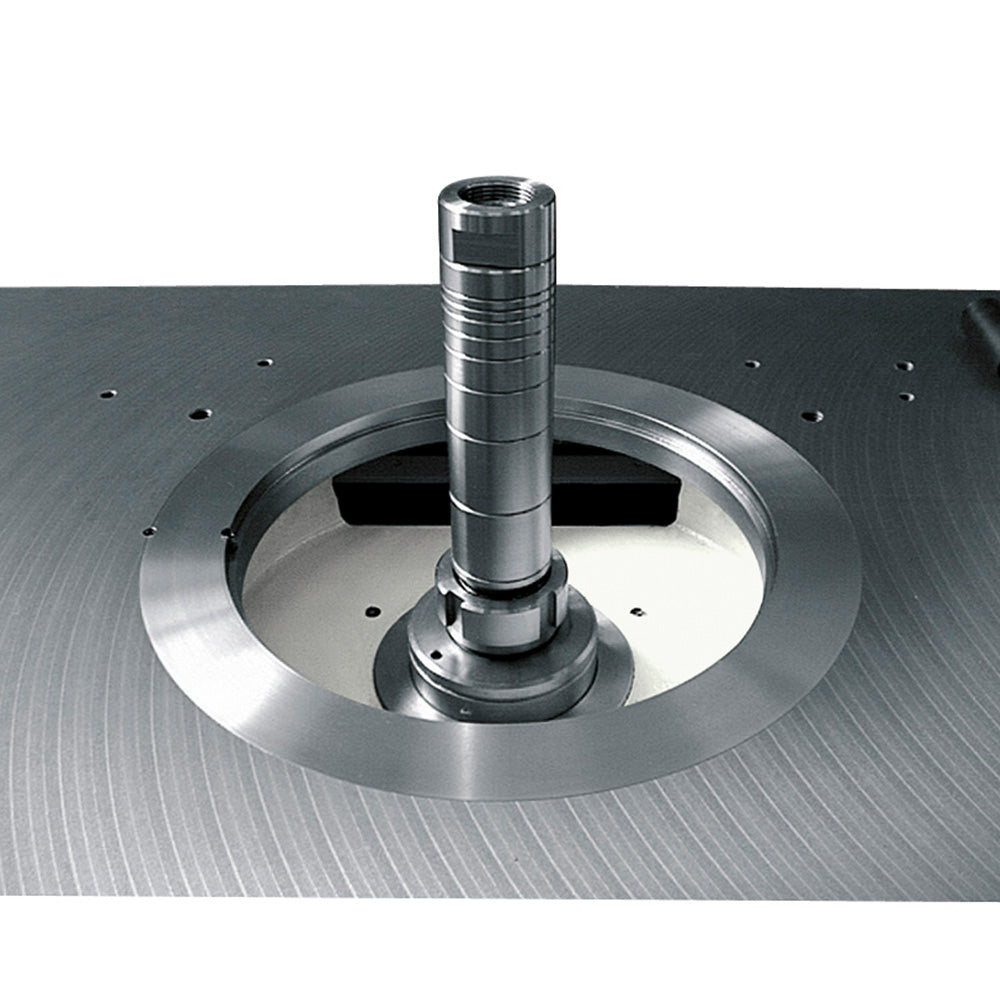

The Class TF 130 from SCM is a fixed spindle shaper built for professionals. The entire spindle unit is surrounded by a cast-iron "cup" that protects the internal components from shavings and sawdust. This machine features an adjustable aluminum fence with memory position pins, easy-to-access and controls, and powerful 11HP motor ready for any task.

The aluminum fence on the Class TF 130 is manually adjustable both forward and backward with respect to the tool line. Manual adjustment is done with the handwheels located behind the fence. The fence also features a memory pin system that allows the operator to remove or reposition it, then easily go back to the position that was marked by the memory pins.

This machine is equipped with a front handwheel for positioning the spindle. This 1-1/4" MK5 spindle is interchangeable, allowing the operator to use spindles with different bore sizes or a spindle with a collet chuck for router bits. There are five spindle speeds to choose from (3,000 / 4,500 / 6,000 / 7,000 / 10,000 RPM) for a variety of applications.

Optional Installation & Training

When purchased, installation will be performed by an SCM factory-trained service technician or certified dealer technician. Installation is defined as assembling the machine to its "ready-to-run" state; it does not include floor/masonry work or running electrical, pneumatic, or dust extraction services. Training will be conducted on site by the technician after installation is completed.

Warranty

SCM warrants that every machine is free of defects in workmanship and materials for a period of one (1) year beginning on the date the machinery is accepted by the customer. Belts, bearings, and common electrical parts carry a six-month warranty. This warranty does not include wearable items or maintenance required in the ordinary course of operation.

Features

- MK5 interchangeable spindle that includes the presetting for "T-SET" rapid tool locking

- Mechanical readout for spindle height

- Aluminum fence with mechanical adjustment

- Memory pins on spindle fence for accurate and repeatable positioning

- 1-1/4" spindle shaft

- Five spindle speeds (3,000 / 4,500 / 6,000 / 7,000 / 10,000 RPM) with speed display dial

- Reverse spindle operation

- Overload switch protection

- Safety microswitch on motor access door

- Emergency push button

- Mechanical brake on main motor

- Foot pedal lock

Specs

Motor Horsepower: 11hp (8 kW)

Worktable dimensions: 47.19" x 28.69" (1,200 x 730mm)

Spindle diameter: 1-1/4"

Working length of spindle: 7" (180mm)

Spindle base projection from table (interchangeable): 3.56" (92mm)

Max. tool diameter retractable under worktable: 12.56" x 3.31" (320 x 85mm)

Dust ports diameter: 4.69" (120mm)

Min. dust collection required: 986 CFM

*Electrical requirements: 220V, 3-phase, 25 A

*Subject to change; must be verified prior to installation.

Includes

- MK5 Spindle (1-1/4")

- Toolbox

Optional Accessories

NOTE: The following accessories are optional and not included with the machine. They can be purchased at any time, but you can also take advantage of Accessory Bundle Pricing (applicable only at the time of machine purchase). Call us at (260) 637-0054 for more information and to place your order!

"LL" Version for profiling

-2 cast-iron worktable side extensions for feeding long pieces.

Carriage on the table

-For small tenoning operations. 60° swiveling fence complete with mobile stops, telescopic extension, and eccentric clamp.

Additional MK5 spindle

MK5 right tool taper

MK5 left tool taper

"T-SET" rapid tool locking

-A simple compressed air gun locks and unlocks the tool.

Manual feed support (horizontal & vertical)

-Vertical adjustment with reference to the workpiece's thickness.

-Horizontal adjustment with reference to the tool diameter. The column support allows the feeder to be excluded/swung away from the table.

FEED 48 Power Feeder

-220V, 3-ph, 4 rollers

*Shipping

Please note: Items being shipped to extremely remote areas or areas with limited delivery access (such as islands only accessible by ferry) may incur additional shipping or freight fees. If your order requires any additional fees other than what is already included in the price, you will be contacted before those fees are applied and before your item ships. This is rare and will not apply to most orders.

**Machinery Availability Key

Availability statuses found above the product description reflect where a machine is in the supply chain at the time of listing. Use the key below to help determine the lead time for this machine.

In stock for immediate shipment: The machine is in OakTree Supply's warehouse and is ready to ship.

In stock as of [date] / Low stock as of [date]: The machine is in the manufacturer’s U.S. warehouse and was available as of the last update we received. Estimated to ship in 3-5 business days. If low stock, please call us before ordering to confirm current availability.

Estimated to ship [date]: The machine is not yet in our warehouse or the manufacturer’s warehouse. The date shown is an estimate based on current production and shipping timelines and may change due to manufacturing schedules, import processing, or freight transit.

Dates listed as “estimated” are not guaranteed and may change. OakTree Supply is not responsible for delays in transit to or from our facility.