SCM Class SI X Sliding Table Saw

- Price

- $ 61,175

Have questions or need help choosing a machine?

Call us at 260-637-0054 or email sales@oaktreesupply.com

Made in Italy. Ships from the United States.

- Freight included in price*

- Factory install included in price

- Low stock as of 2.18.26**

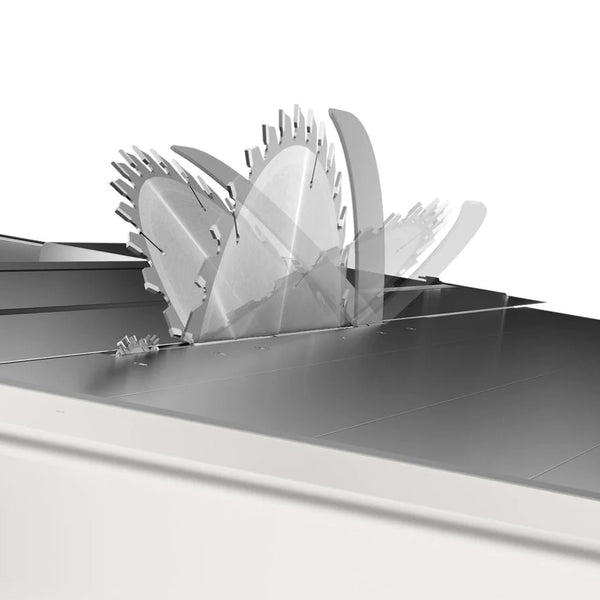

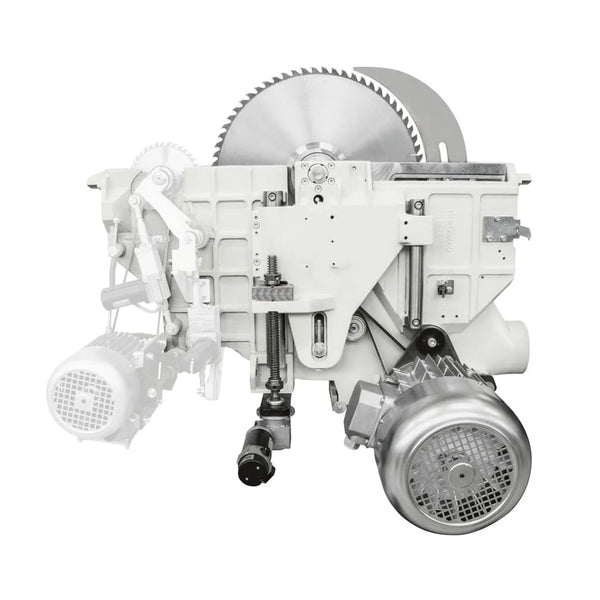

The Class SI X is capable of simultaneously using a 550mm saw blade and 160mm scoring blade, for both 90° and ± 46° inclined cuts, providing the best performance on veneered panels and solid wood components. Featuring a 10.5’ sliding table, 14HP main motor, and an overhead EASY 3 UP PLUS control panel, this saw is designed for high production shops and professionals who want the most out of a sliding table saw.

The anodized aluminum alloy carriage on the Class SI X Saw will never require adjustment and can bear heavy loads thanks to arch-ground hardened steel slideways. The "arc" profile of the slideways ensures higher loading capacity, and no play and no need for adjustments over time. The carriage sliding system comes with an SCM 10-Year Guarantee.

Featured on the Class SI X is the "EYE-S Mini," a 10" electronic control panel. This panel gives the operator direct control to lift the blade, set the blade tilt, and move the parallel fence. The operator has four mode options for these settings: manual, manual incremental, semi-automatic, and automatic. The EYE-S Mini also has a storage capacity for up to 1,000 programs.

Utilize SCM's Thundercut App to get the most out of the Class SI X. This app is compatible with iOS and Android operating systems, and allows you to:

- Manage stock material and guides you through the cut

- Create and modify projects, import projects from the main furniture design software ("cpout" file format), and import cutting lists

- Choose different cutting patterns based on app's suggestions, such as "minimum waste," "maximum speed," etc.

- View machine configuration in 2D or 3D

- Print panel labels

Installation & Training

Installation will be performed by an SCM factory-trained service technician or certified dealer technician. Installation is defined as assembling the machine to its "ready-to-run" state; it does not include floor/masonry work or running electrical, pneumatic, or dust extraction services. Training will be conducted on site by the technician after installation is completed.

Warranty

SCM warrants that every machine is free of defects in workmanship and materials for a period of one (1) year beginning on the date the machinery is accepted by the customer. Belts, bearings, and common electrical parts carry a six-month warranty. This warranty does not include wearable items or maintenance required in the ordinary course of operation.

Features

- Anodized aluminum alloy sliding carriage on high precision arch-formed hardened steel guides

- EYE-S Mini 10" panel features four modes of direct control for lifting the main blade, tilting both blades, and moving the parallel fence

- "AP System" automatic positions the overhead protection in relation to the tilt of the blade (SCM Patent)

- Programmed parallel fence with 1,600mm cutting width

- Squaring frame on swinging arm support complete with fast fence positioning for angular cuts and an idle roller to facilitate panel loading

- Telescopic fence with 2 flip-over stops and imperial ruler tilted towards the operator

- Integrated motor start/stop buttons in the sliding carriage

- Inverter for electronic speed change (3,000 - 5,000 RPM)

Outfeed table extensions - 10 year guarantee for the carriage sliding system

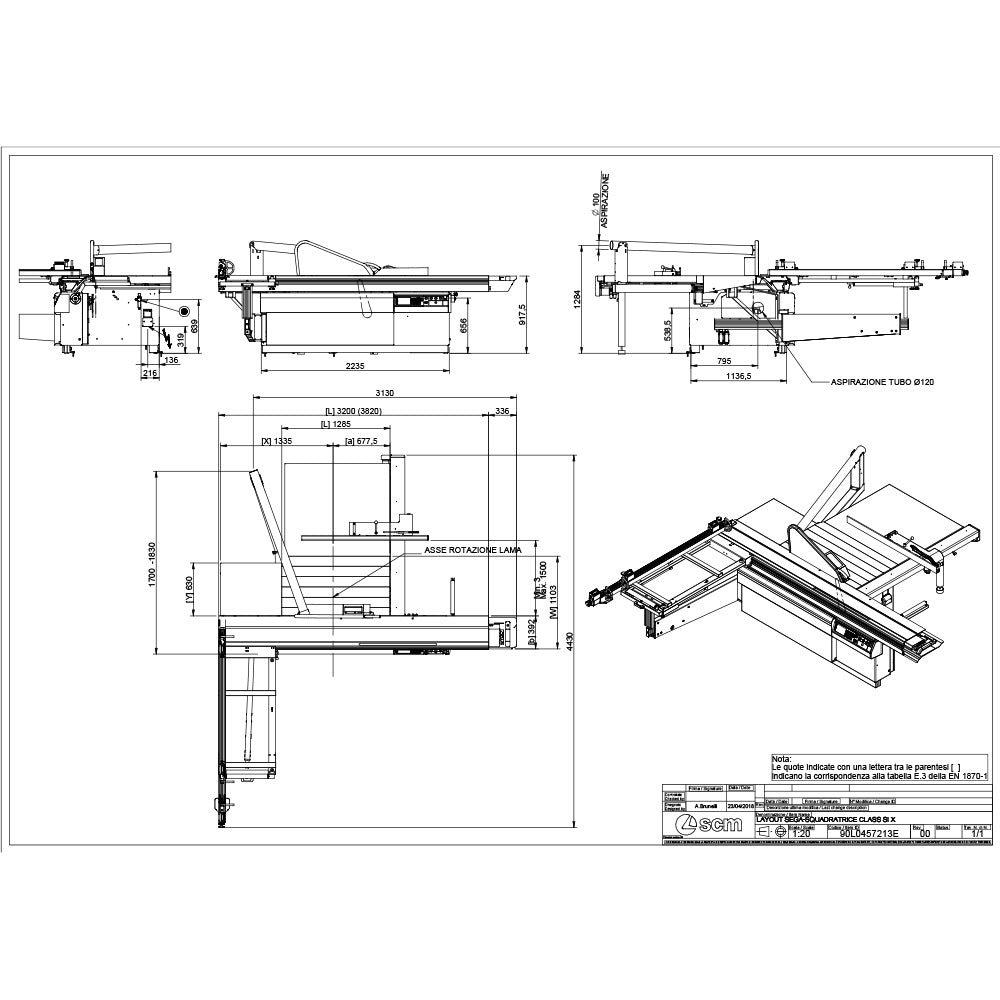

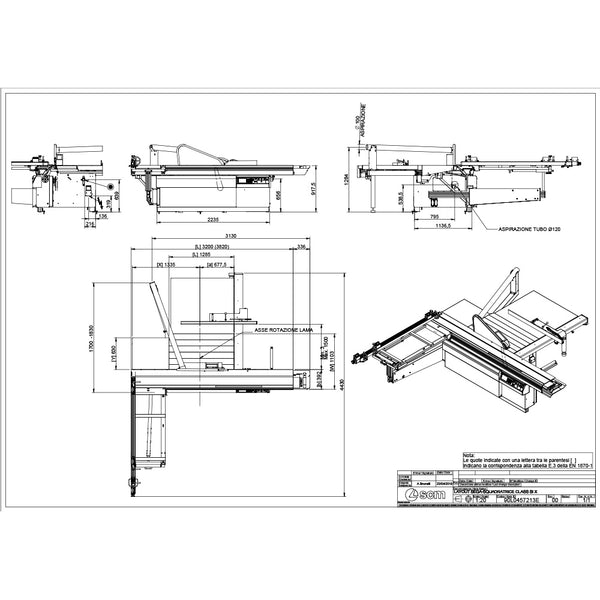

Specs

Main blade motor: 14hp

Max. saw blade dia.: 550mm (21.62")

Blade arbor: 30mm (1.18")

Diameters to be used simultaneously: 450 x 160mm (17.69" x 6.25")

Main blade speed: 3,000 - 5,000 RPM (w/inverter)

Blade tilting: 46° - -46°

Max. cutting height at 90°: 200mm (7.81")

Max. cutting height at 45°: 130mm (5.06")

Max. cutting height at -45°: 105mm (4.12")

Max. squaring stroke: 3,200mm (10.5')

Cutting width on fence: 1,600mm (63")

Dust collection outlet: 120mm (4.69")

*Electrical requirements: 220V/400V, 3-phase, 60 Hz (this machine is 400V. This configuration includes an autotransformer 220V - 400V)

*Subject to change; must be verified prior to installation.

Includes

- Saw blade, 350mm

- Eccentric clamp

- Trimming shoe

- Push stick

- Push handle

- Toolbox

*Shipping

Please note: Items being shipped to extremely remote areas or areas with limited delivery access (such as islands only accessible by ferry) may incur additional shipping or freight fees. If your order requires any additional fees other than what is already included in the price, you will be contacted before those fees are applied and before your item ships. This is rare and will not apply to most orders.

**Machinery Availability Key

Availability statuses found above the product description reflect where a machine is in the supply chain at the time of listing. Use the key below to help determine the lead time for this machine.

In stock for immediate shipment: The machine is in OakTree Supply's warehouse and is ready to ship.

In stock as of [date] / Low stock as of [date]: The machine is in the manufacturer’s U.S. warehouse and was available as of the last update we received. Estimated to ship in 3-5 business days. If low stock, please call us before ordering to confirm current availability.

Estimated to ship [date]: The machine is not yet in our warehouse or the manufacturer’s warehouse. The date shown is an estimate based on current production and shipping timelines and may change due to manufacturing schedules, import processing, or freight transit.

Dates listed as “estimated” are not guaranteed and may change. OakTree Supply is not responsible for delays in transit to or from our facility.