SCM Minimax ME 35ETR Edgebander with Pre-Milling & Corner Rounding - 3PH, 220V

- Price

- $ 41,275

Have questions or need help choosing a machine?

Call us at 260-637-0054 or email sales@oaktreesupply.com

Made in Italy. Ships from the United States.

- Freight included in price*

- Factory install included in price

- Low stock as of 1.23.26**

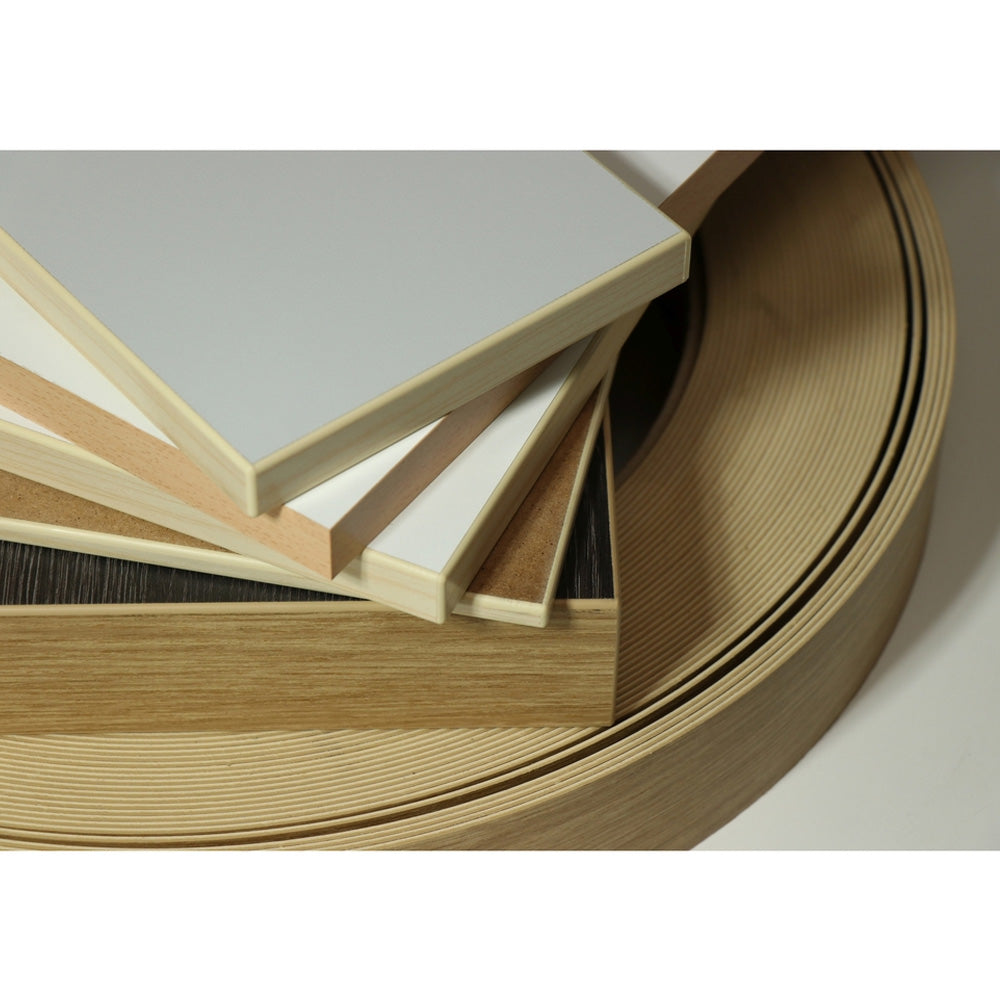

The Minimax ME 35TR is a 3-phase automatic edge bander with great flexibility for both thin and thick edges. It intends to bridge the gap between a traditional small to mid-sized edge bander to the more robust equipment used in the Classical line of products. Two of the key features are the pre-mill and corner rounding units. There is no competition in the U.S. market for such a small, versatile machine with pre-mill or corner rounding that is so economical!

This machine is meant to be used with melamine edges, PVC, and ABS up to 3 mm. It contains features usually only found on much larger and expensive machines. The ME 35TR comes with an anti-adhesive unit, pre-milling unit, end-cutting/corner rounding, top and bottom trimming, edge scraping, and buffing unit, with 3 mm edge processing tooling in coils.

The Minimax 35ETR comes with the Eye-S, a touch screen control panel loaded with features to make edge banding applications easy. It allows you to choose the type of material you’re working with (MDF, chipboard, etc.), set the height and thickness of material, and adjust the glue temperature and type, among other things. All edge banding functions are shown graphically on the screen, so it leaves little room for errors or confusion.

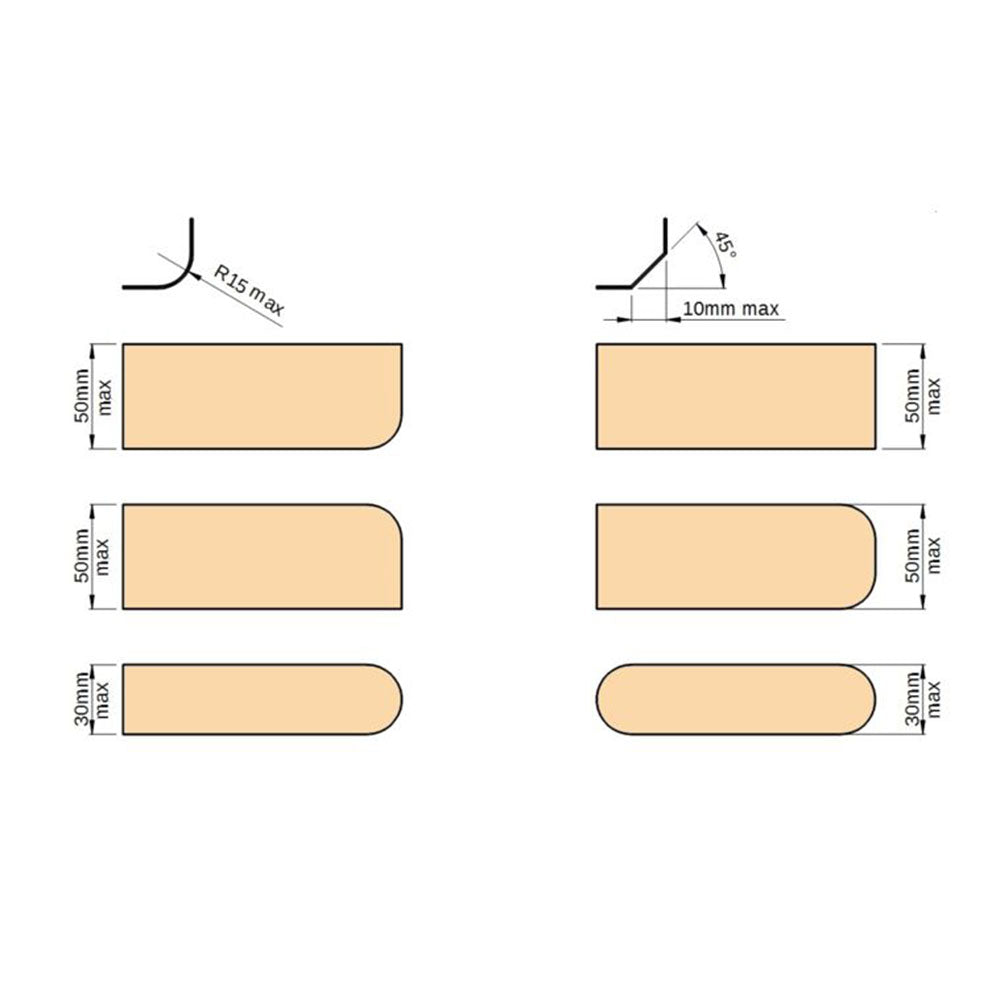

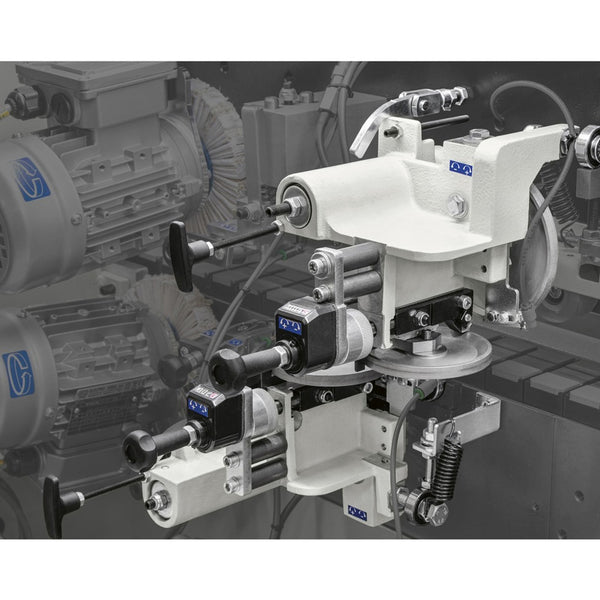

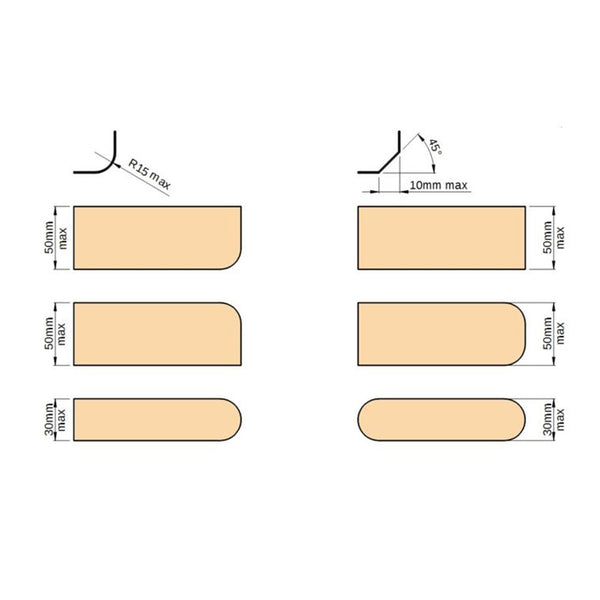

Most notable is the full corner rounding end-trimming unit. During the process of removal of the front and rear exceeding edge, this two stage unit trims and rounds the edge in a single pass at the end of the panel. Driven directly from the control panel it is possible to work with only the end cutting function for thin tape and 3mm thick banding. This is the first unit in its class to have this advanced engineering, this small of a footprint, and overall capabilities at a price point that allows the small to medium-sized shop to compete.

Premiered at the Xylexpo in Europe, the Minimax ME 35TR won first place under the “tooling machine” category for its ability to combine the corner-rounding and trimming features into a single tool, compact-sized machine with a minimal footprint. This applied technology makes this edge banding machine a must-have product for small to medium sized facilities. The ideal one-stop machine for facing and trimming the front and rear ends of panels, while at the same time, rounding the front and back edges all at an affordable price for every shop.

Units included on the ME 35ETR:

- Pre-Milling

- Glue Pot

- Combined End-Cutting/Rounding

- Top/Bottom Trimming

- Profile Scraping

- Brushing (Buffing)

Also available in single phase.

ME Edgebander Comparison Chart >

Features

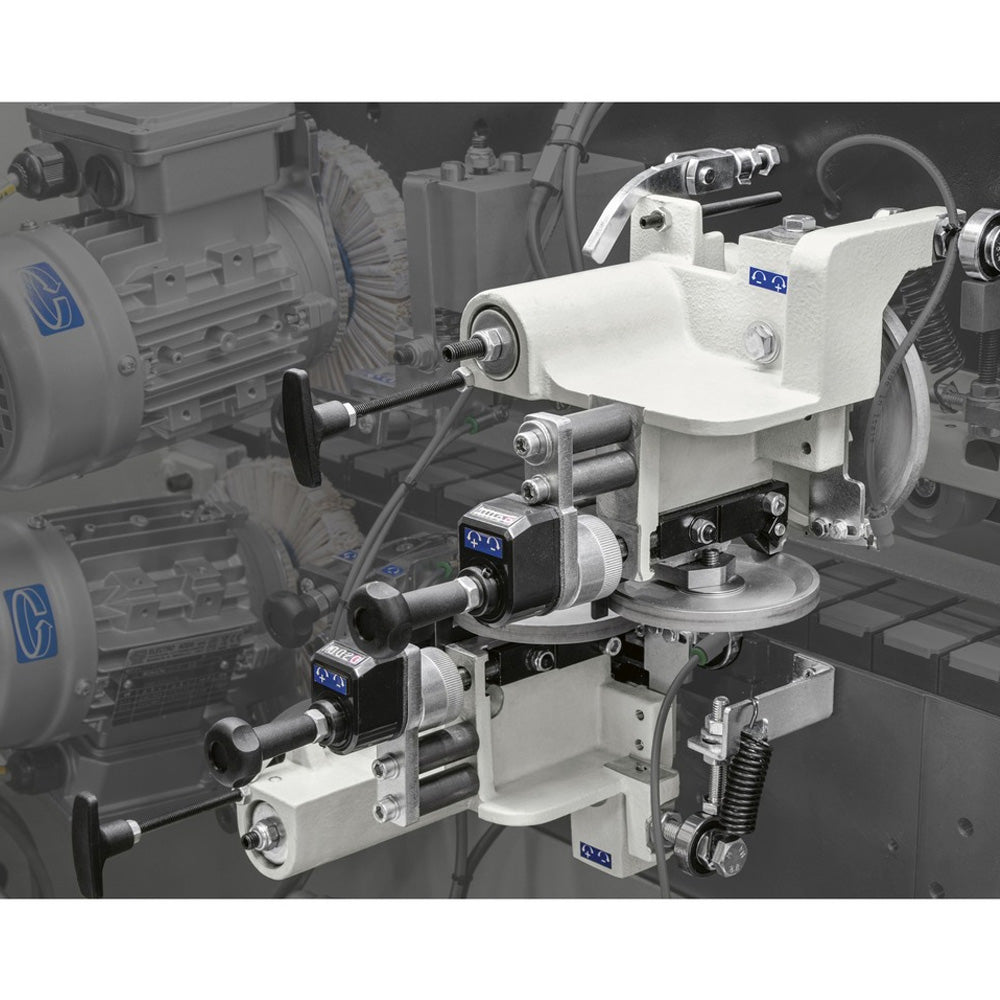

- Each station on the edge bander is easily adjustable and repeatable through the use of digital mechanical readouts

- Pre-milling unit allows you to panel edge surfaces without any imperfections before gluing operation

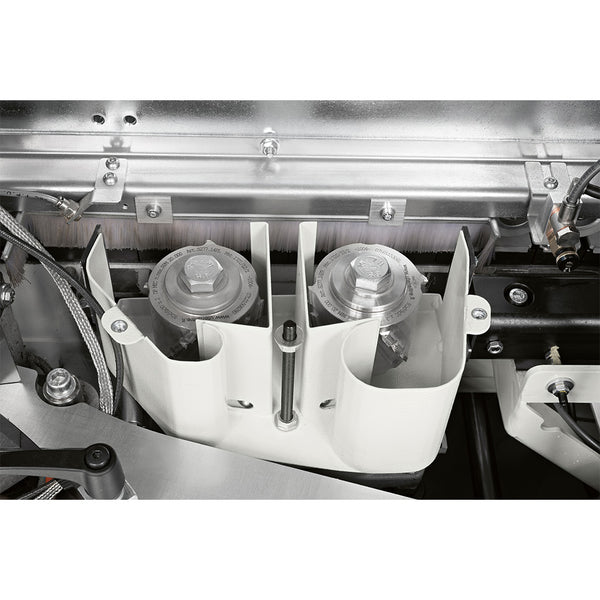

- Pre-milling unit is complete with two diamond cutters 80 mm in diameter

- Vertical adjustment of pre-milling unit allows for even tool wear

- Self-lubricating glue pot is Teflon coated to allow for easy clean up and replacement

- Intuitive EYE-S Touchscreen Control Panel

- Top/Bottom trimming unit provided with 55.3 mm diameter combined cutters: the radius part of the cutter is used to trim 3 mm radius edges and chamfered thin edges

- Anti-adhesive unit prevents glue from sticking to the upper and lower panel surfaces, improving cleaning

- Extreme reliability thanks to high frequency motors

- Track feed panel movement system allows for precise and accurate positioning of the panel through each station

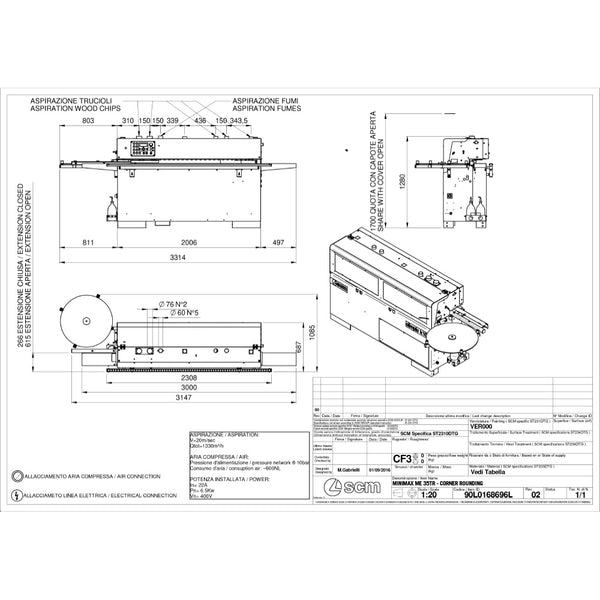

Specs

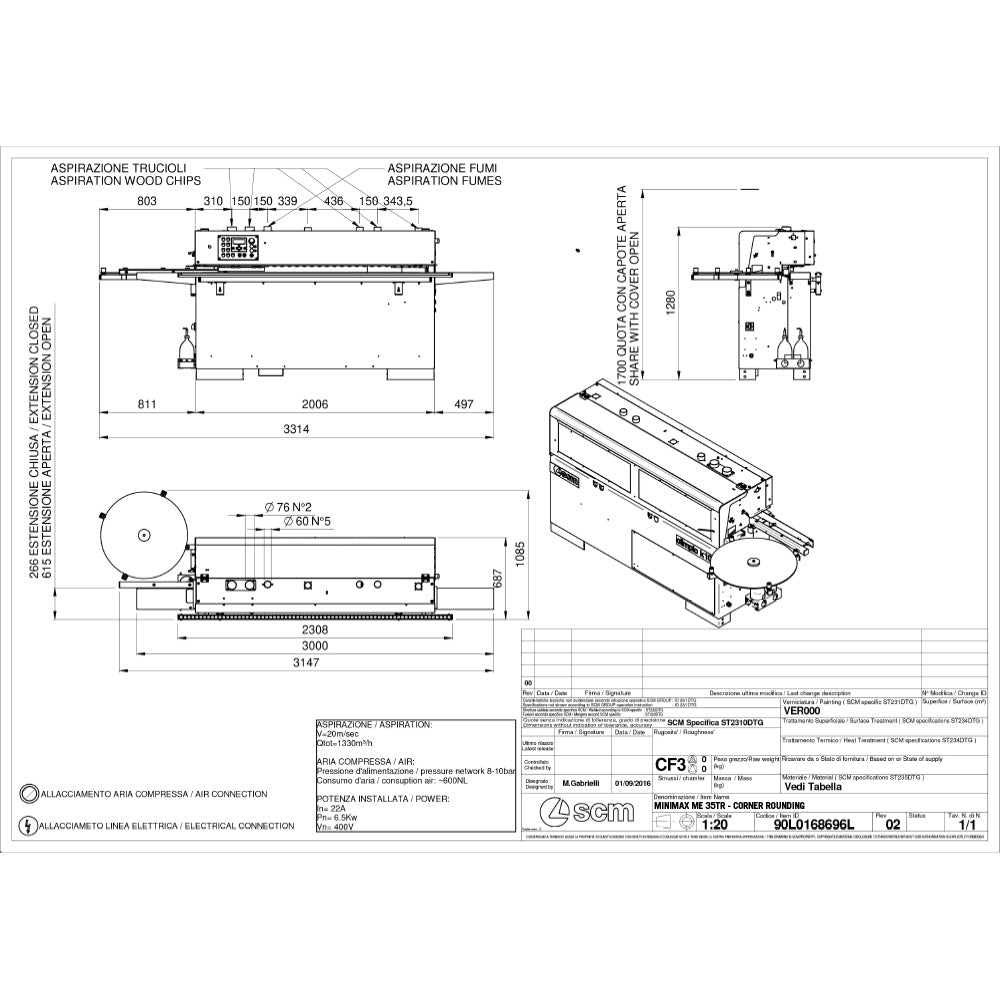

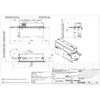

Pneumatic operating pressure: 6.5 bar

Exhaust outlets - Pre-Milling Unit (x2): 3” (76 mm)

Exhaust outlet - Glue Pot: 2.36” (60 mm)

Exhaust outlets – Edge Bander Unit Stations (x3): 2.36” (60 mm)

Worktable dimensions: 118” x 20.6” (3,000 mm x 525 mm)

Worktable height: 35.5” (904 mm)

Thickness of rolled edges: 0.4 - 3mm

Min. to max. panel height: 8 - 50 mm (.31” – 1.94”)

Min. panel length/width with rolled edges: 120/110 mm (4.72”/4.33”)

Feed speed: 7 m/min (23 fpm)

Feed motor power: .87hp (.65 kW)

Operating temperature: 68 - 374°F (20 - 190°C)

Min. dust collection required: 890 CFM

Electrical requirements*: 220V, 60Hz, 3-phase, ~30 A

*Subject to change; must be verified prior to installation.

Pre-Milling Unit

Motor power: 4hp (3 kW)

Diamond cutter: Ø 80mm Z2 H=56

Blade rotation speed: 7,200 RPM

Stock removal: 0 - .08" (0.5 - 2 mm)

Glue Pot Unit

Motor power: .4hp (.3 kW)

Glue capacity: 2 lbs. (~0.8 kg)

Combined End Cutting-Rounding Unit

Motor power: .3hp (.2 kW)

Cutter: Ø 58mm Z4

Blade rotation speed: 12,000 RPM

Trimming Unit

Motor power: 2x .47hp (.35 kW)

Widia cutters: Ø 55.3 mm Z3

Cutters rotational speed: 12,000 RPM

Vertical/horizontal copying devices: Rotating/rotating

Brushing (Buffing) Unit

Motor power: 2x .23hp (.17 kW)

Speed: 2,800 RPM

Includes

- Corner Rounding end cutting unit for cutting and rounding of the panel (not suitable for processing of wood edges)

- Panel edge trimming unit for straight or radius trimming on thick or thin materials; PVC, ABS, Melamine and Laminate

- Kit for glue pot rapid substitution that allows for the glue pot tank to be easily removed and replaced (does not come with spare glue pot)

- Gluing unit with auto-sensory cooling to avoid burning of glue

- Glue spreading roller with electrical resistance inside provides a uniform glue spread at maximum working temperature for the entire length of the roller

- End cutting unit with high frequency motor for the highest-quality finish

- Top/Bottom trim unit with front and vertical copy shoes and high frequency motors for faster rotating speeds

- Cutters designed for straight or radius trimming with numerical readout setup

- Radius edge scrape for use on PVC/ABS edges with manual exclusion of the device when not in use

- Tilted, vertically adjustable brushing unit motors for the polishing and finishing on the panel edge and joints

- 2 mm tooling

*Shipping

Please note: Items being shipped to extremely remote areas or areas with limited delivery access (such as islands only accessible by ferry) may incur additional shipping or freight fees. If your order requires any additional fees other than what is already included in the price, you will be contacted before those fees are applied and before your item ships. This is rare and will not apply to most orders.

**Machinery Availability Key

Availability statuses found above the product description reflect where a machine is in the supply chain at the time of listing. Use the key below to help determine the lead time for this machine.

In stock for immediate shipment: The machine is in OakTree Supply's warehouse and is ready to ship.

In stock as of [date] / Low stock as of [date]: The machine is in the manufacturer’s U.S. warehouse and was available as of the last update we received. Estimated to ship in 3-5 business days. If low stock, please call us before ordering to confirm current availability.

Estimated to ship [date]: The machine is not yet in our warehouse or the manufacturer’s warehouse. The date shown is an estimate based on current production and shipping timelines and may change due to manufacturing schedules, import processing, or freight transit.

Dates listed as “estimated” are not guaranteed and may change. OakTree Supply is not responsible for delays in transit to or from our facility.