SCM Minimax ME 28ET Automatic Edgebander with Pre-Milling - 1PH, 230V

- Price

- $ 25,475

Have questions or need help choosing a machine?

Call us at 260-637-0054 or email sales@oaktreesupply.com

Made in Italy. Ships from the United States.

- Freight included in price*

- Factory install included in price

- Next available: Late December 2025

The Minimax ME 28ET is a compact machine boasting capacities usually only found on much larger units. This model comes with a single diamond pre-milling unit with chip breaker, end trimming, top and bottom trimming, scraping, buffing stations, and 3 mm edge processing (5 mm strips) standard. This machine is perfect for the small to medium sized panel processing shops, this small machine packs many features, and has a favorable price as well.

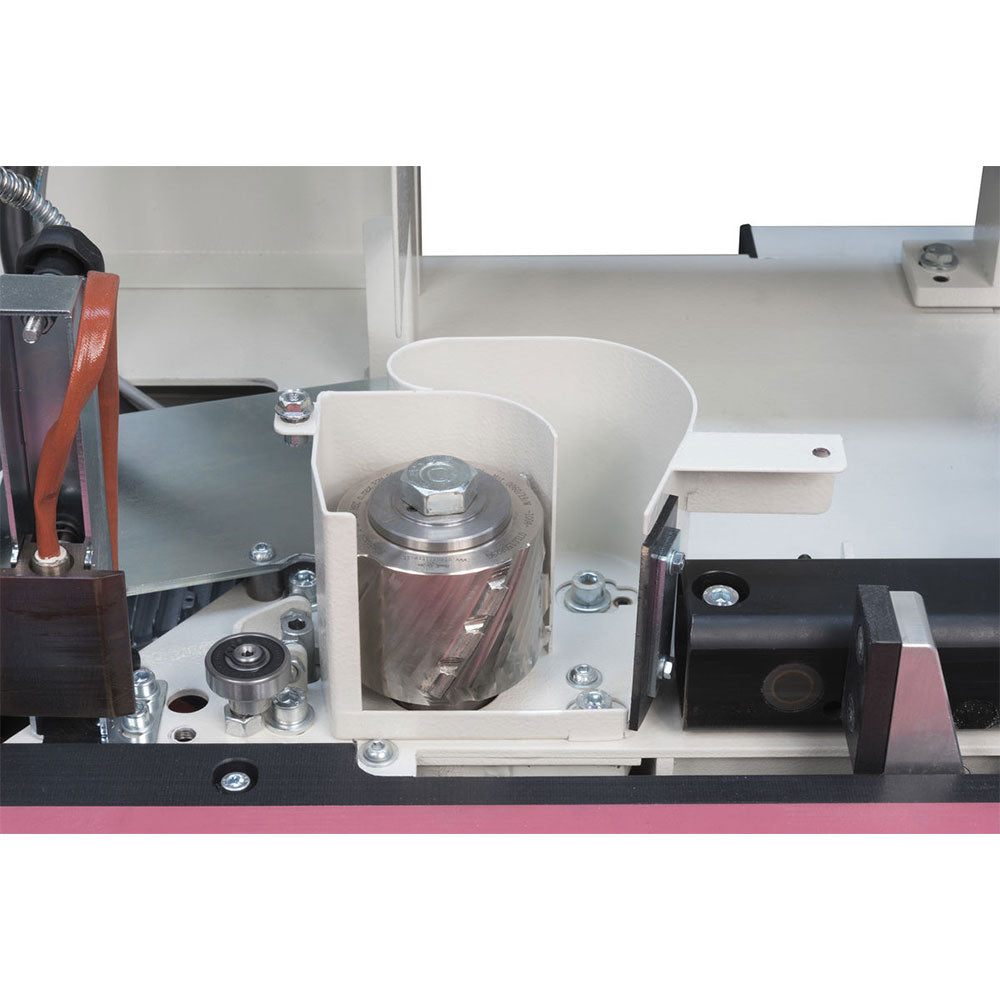

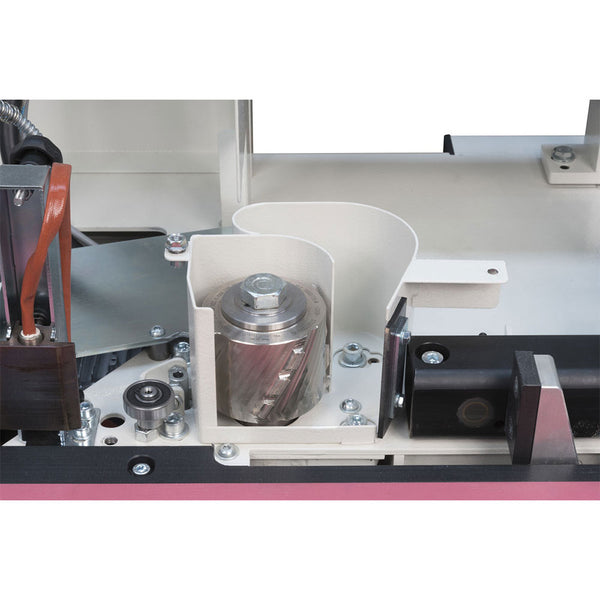

Create panel edge surfaces without any imperfections before the gluing operation. The single head diamond pre-mill and chip breaker ensures a clean edge that corrects any panel imperfections caused by the saw cutting and panel storage process. The independent exhaust system comes equipped with an exhaust hood and air blower which cleans and removes all dust and chips from the panel and stations. Four different thickness removals: 0.5 / 1 / 1.5 / 2 mm.

The ME 28ET Edgebander features a glue pot with a quick heat-up system. The glue pot is Teflon coated to allow for easy clean up and easy glue replacement. The system easily applies the glue to the panel with a vertical glue spreading roller, and the temperature is adjustable via the PLC control. The machine also has a device to automatically recover unused glue and has a standby mode while idle.

The ME 28ET panel movement system is designed for a perfect finish and further improved by the panel conveying belt (SCM patent), which prevents the panel from having the feed affected by the typical pulse generated by the pinion of a traditional feed track, which is common at slower speeds. The presser above the belt feed has support rollers that run the entire length of the machine's stations to assist guiding the panel during operation.

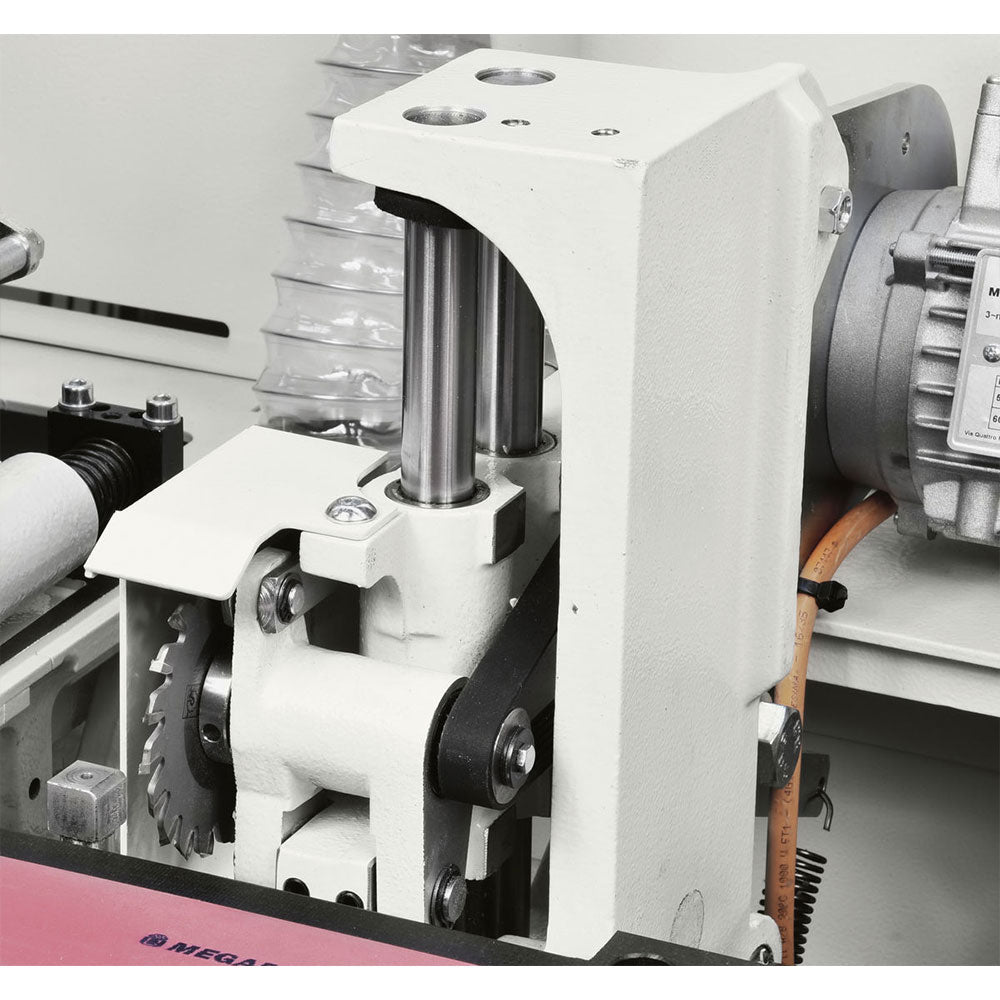

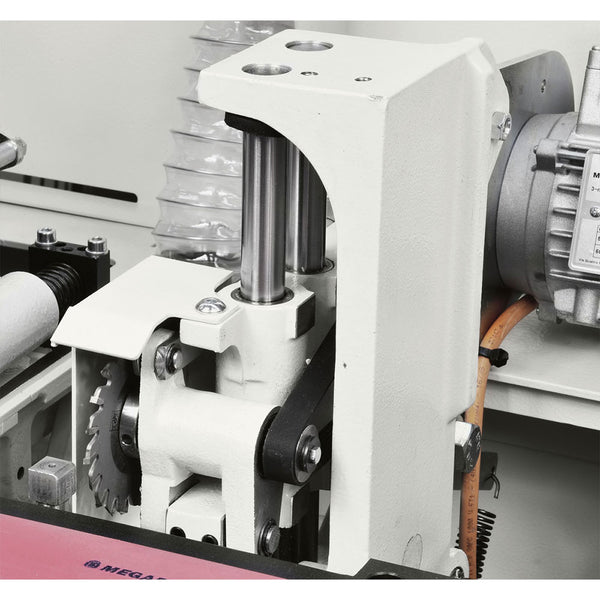

The saw blade end trimmer is extremely precise. Made of solid steel, it guarantees a clean, accurate cut on the leading and trailing edges of the panel being processed. This saw blade trims both the front and rear leading edges of the panels being run. The process is completely automatic and the cut is referenced directly from the panel via micro-switches so there is no need for adjustment when running different length panels.

The ME 28ET features buffing and scraping stations as standard for finishing 3 mm PVC/ABS edges. The scraping system assures an excellent finish, free of chatter marks and accurate positioning of the knives, thanks to the heavy-duty structure. The precise horizontal and vertical copy shoes have high-polished chrome plated surfaces that provides a scratch resistant surface for delicate materials.

Units included on the ME 28ET:

- Pre-Milling

- Glue Pot

- End Cutting

- Top/Bottom Trimming

- Profile Scraping

- Brushing (Buffing)

Also available in 3-phase.

ME Edgebander Comparison Chart >

Features

- Single-head diamond pre-mill and chip breaker correct any panel imperfections caused by saw cutting and panel storage process

- 4-line LCD display with "soft touch" push buttons and LED light indicators for functions and glue temperature adjustment

- Panel conveying rack ensures a smooth and linear panel movement

- Ribbed steel machine frame guarantees excellent support

- Top thick steel pressure beam with rubber-coated wheels

- Panel support roller can be extended the entire length of the machine

- Numeric indicator of selected panel thickness

- Automatic recovery of unused glue

- Adjustable infeed fence with numeric readout

- Copying device allows for blade alignment and ensures a constant and precise cut under any working condition

- Top/Bottom trimming unit equipped with vertical and horizontal copying pads for accurate tool positioning

- Easily change between radius and flat trimming

Specs

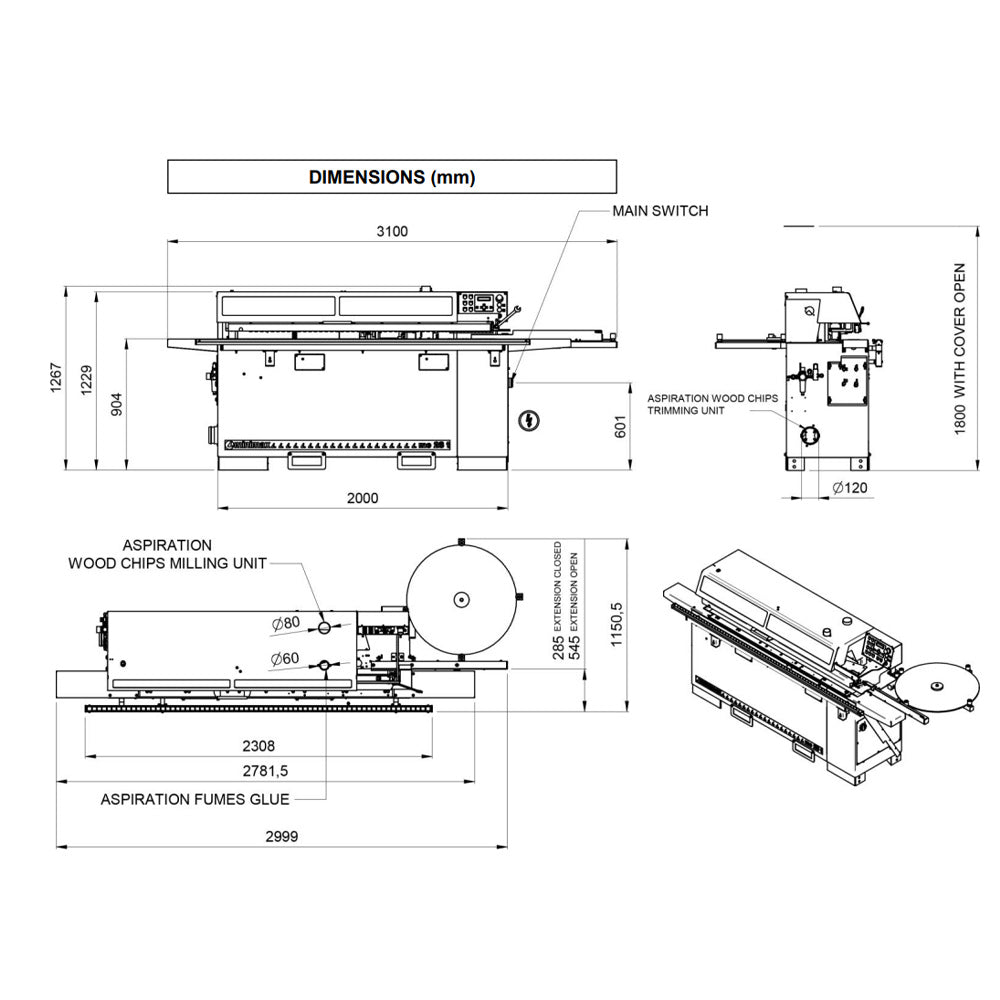

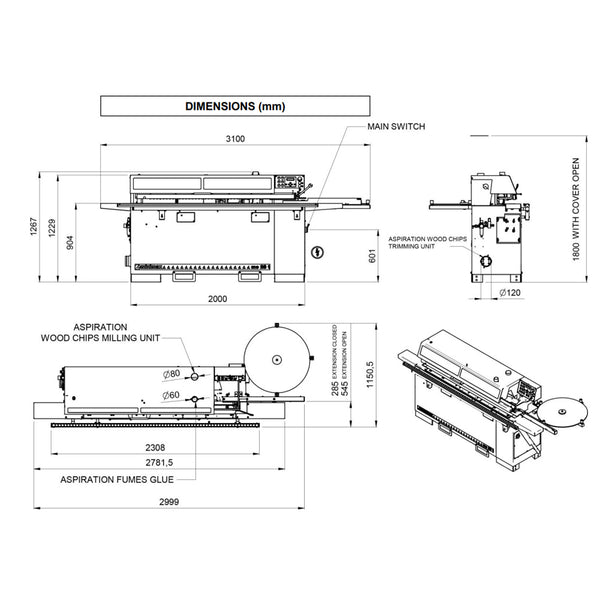

Compressed air requirement: 6.5 bar

Exhaust outlet diameter (base): 4.72” (120 mm)

Exhaust outlet diameter (glue pot): 2.36” (60 mm)

Recommended duty cycle: 3 – 4 hours

Banding thickness: .016” - 0.12” (0.4 mm - 3 mm)

Max. thickness of banding in strips: .20” (5 mm)

Panel thickness: .47” – 1.96” (12 mm – 50 mm)

Min. - Max. panel height using edge scraping unit: .63” – 1.96” (16 mm – 50 mm)

Min. panel length/width with rolled edges: 7.48” / 4.33” (190 mm / 110 mm)

Min. panel length (frontal end cutting only): 4.72” (120 mm)

Worktable dimensions: 114.1” x 22.4” (2,900 mm x 570 mm)

Worktable height: 35.6” (904 mm)

Feed motor power: .7 Hp (.55 kW)

Feed speed: 23 ft/min (7 m/min)

Operating temperature: 68°F - 374°F (20°C - 190°C)

Electrical requirements*: 230V, 60Hz, single-phase, 46 A

Shipping weight: 1,184 lbs.

*Subject to change; must be verified prior to installation.

Pre-Milling Unit

Motor: 2.95hp (2.2 kW)

Diamond cutter: Ø 80mm Z2 H=56

Blade rotation speed: 7,000 RPM

Stock removal: 0 - .08" (0 - 2 mm)

Glue Pot Unit

Motor power: .28hp (.21 kW)

Glue capacity: 2 lbs. (~0.8 kg)

End Cutting Unit

Motor power: .88hp (.66 kW)

End cutting blade: Ø 90mm Z20

Blade rotation speed: 12,000 RPM

Trimming Unit

Motor power: 2x 1.74hp (1.3 kW)

End cutting blade: Ø 75mm Z4

Cutters rotation speed: 12,000 RPM

Brushing Unit

Motor power: 2x .4hp (.3 kW)

Brush rotation speed: 2,800 RPM

Includes

- Pre-Mill diamond cutters

- Radius tooling set (2 mm)

- Toolbox

Video

*Shipping

Please note: Items being shipped to extremely remote areas or areas with limited delivery access (such as islands only accessible by ferry) may incur additional shipping or freight fees. If your order requires any additional fees other than what is already included in the price, you will be contacted before those fees are applied and before your item ships. This is rare and will not apply to most orders.