SCM Minimax CU 300C - Tersa Full Combination Machine - 5.5' Slider

- Price

- $ 14,275

Have questions or need help choosing a machine?

Call us at 260-637-0054 or email sales@oaktreesupply.com

Made in Italy. Ships from the United States.

- Freight Included In Price*

- Estimated to ship April 2026**

SCM's most popular combination machine for years sets the bar higher than any other manufacturer. This machine has proven itself in American shops countrywide. It boasts a 5.5’ sliding table (8.5’ also available), and has features normally found on much more expensive machines for a fraction of the cost. See for yourself why the Minimax CU 300C Combination Machine is the perfect solution for people who want quality equipment with a small machine footprint.

This Italian-made machine comes standard with scoring. This allows you to not only accurately cut panels, but you can cleanly cut them too. This is important when cutting particle board, melamine, laminated panels, or anything else to which you want to apply some type of edge banding. If you are cutting solid wood, simply drop it below the table surface independently of the main blade. A 12” main blade capacity is featured without having to remove the scoring blade.

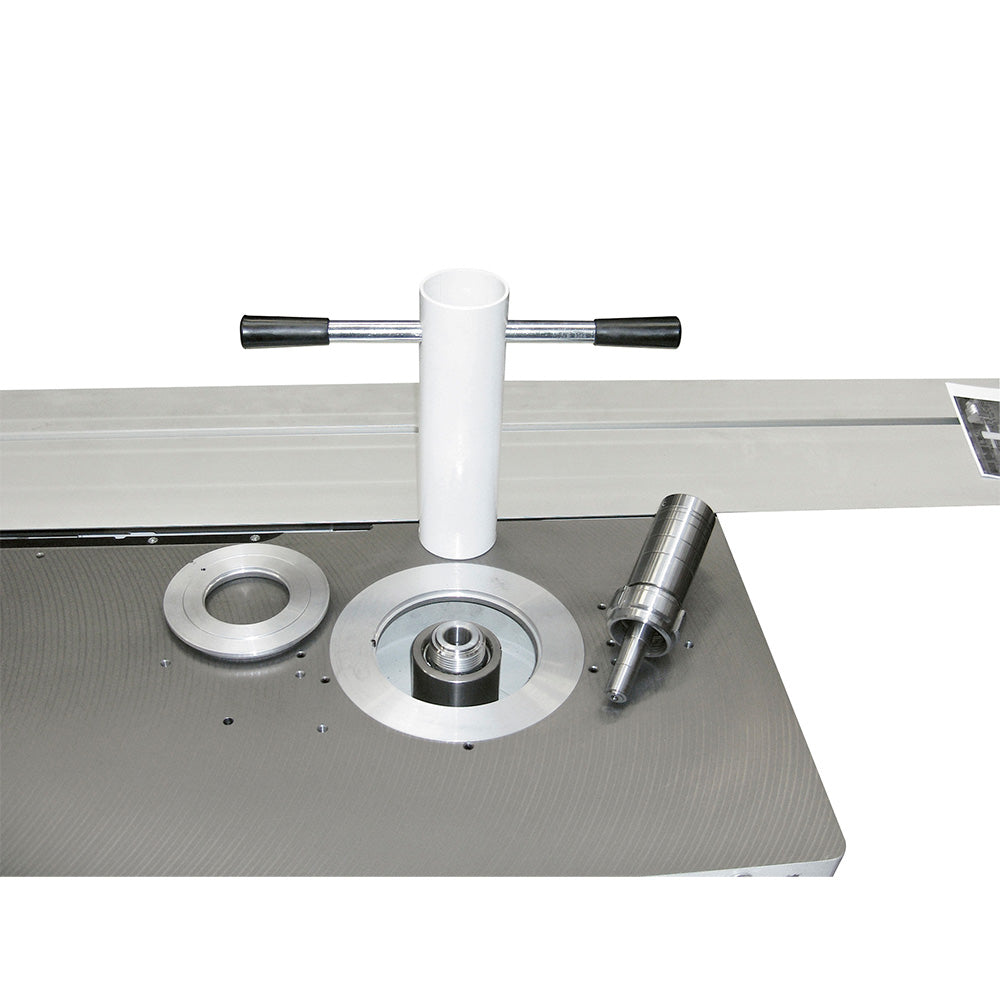

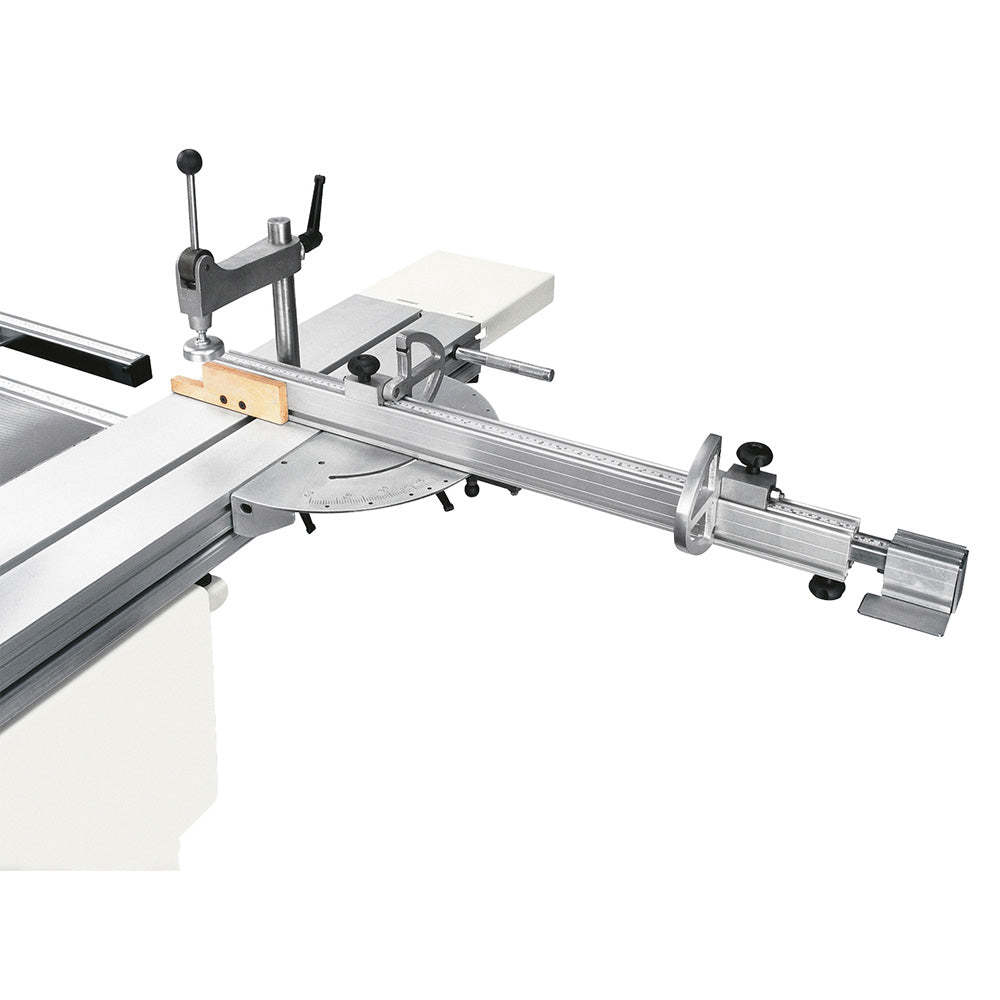

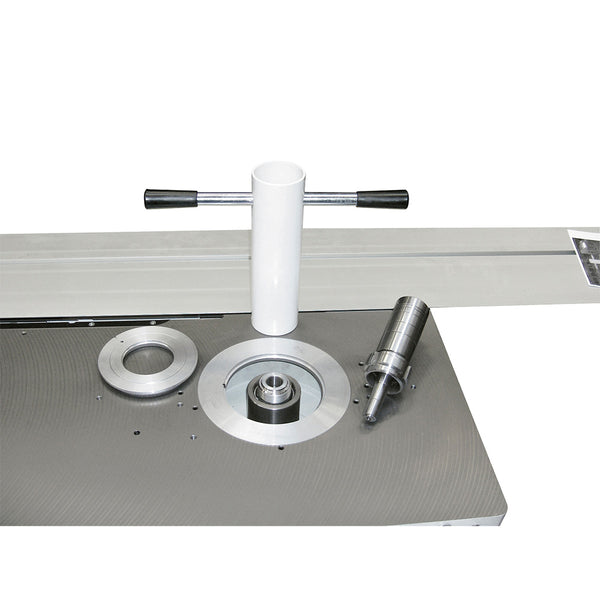

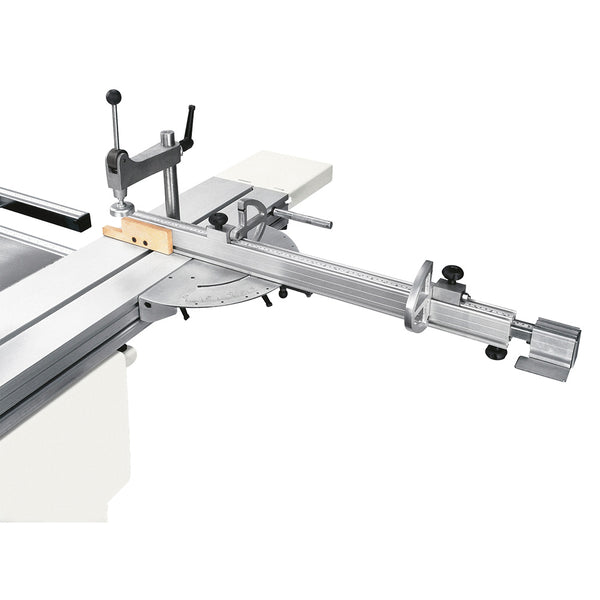

The separate miter gauge allows the user to keep the main crosscut fence at 90° and use the separate miter gauge to do the angled cuts, saving time when mitering small panels. The CU 300C also comes with a 4-speed shaper as standard equipment. The spindle is 1.25” diameter, and is interchangeable to allow for spindles of different sizes. You can easily use the Shaper in conjunction with the slider for a more versatile machine. Reversing is also standard.

A separate heavy-duty jointer fence is included, which mounts to a cast-iron knuckle and tilts up to 45°. This machine comes standard with a feature which allows you to use the post from the eccentric clamp to extend the ripping capacity of the sliding table saw of up to 32”.

The Minimax CU 300C also comes standard with a cast-iron mortiser. The mortiser has vertical and horizontal movement with positive stops. A separate post is supplied to mount the eccentric clamp to secure your material. It also comes with a Wescott Self-Centering chuck. The Minimax CU 300C comes standard with a mobility kit so that you can easily maneuver it into tight spaces. As heavy as it is, it is quite nimble.

This machine comes with a "Tersa" Knife cutterhead. Tersa Knives are double-sided for long life, disposable, and lock into place when you start the machine — no special tools required! These knives also have one of the quickest changeover times in the industry. Available in different materials and designs for different types of wood. Click the link below to see all Tersa Knives.

Features

- Incredible cutting of both very thick solid wood and panels, even those veneered, thanks to the saw unit with a blade that has a maximum diameter of 315 mm that grants a 100 mm cutting height with the scoring blade installed

- Equipped with a saw-planer multifunction fence, designed to be easily positioned and removed to allow rapid work changeover

- Cast-iron structure

- Closed off by a cast iron “cup” to protect mechanical components inside the machine from sawdust, shavings, and dirt

- Handwheel with gravitational numerical readout

- Belt driven scoring unit allows for tool-less adjustments outside the machine

- Precise and safe machining with the spindle moulder fence with micrometric adjustment complete with vertical and horizontal pressers

- Quick changeover thanks to the unique dual dust hood design in which you don’t have to drop the planer table all the way down to switch to a jointer and vice versa

- Dado set capability (blade not included)

- Workpieces with a maximum height of 230 mm can be machined to the thicknesser

- Planer unit in the standard version has a 72 mm diameter cutter block with 3 knives

- Heavy outrigger mounts to the sliding table for processing large piece

- Jointer tables open up away from the operator, and they open together making planing operations much easier

- Pressure of the thicknesser feed rollers can be adjusted according to the type of wood machined

- Rip fence is attached to the jointer table so that it does not disrupt the flow of material through the planer

- Sandblasted steel outfeed roller maintains the perfect post-machining finish.

- The design of the dust conveyor, protecting the cutter block, is specifically intended to further increase system safety and efficiency

- Made in Italy

Specs

Electrical: 230V

Horsepower: 4.8hp

Recommended Circuit: 30 amp

Min. dust extraction volume: 600 CFM

Net weight: 1,400 lbs.

Jointer

Working width: 12"

Total jointer table length: 59" (1510 mm)

Cutterhead speed: 5,200 RPM

Max. depth of cut: 0.125"

Fence size/tilt: 6" x 51" / 0° - 45°

Planer

Table size: 12" x 22.25"

Max. working thickness: 9"

Min. working thickness: 0.125"

Max. stock removal: 1/8"

Feed speed: 23 fpm

Table Saw

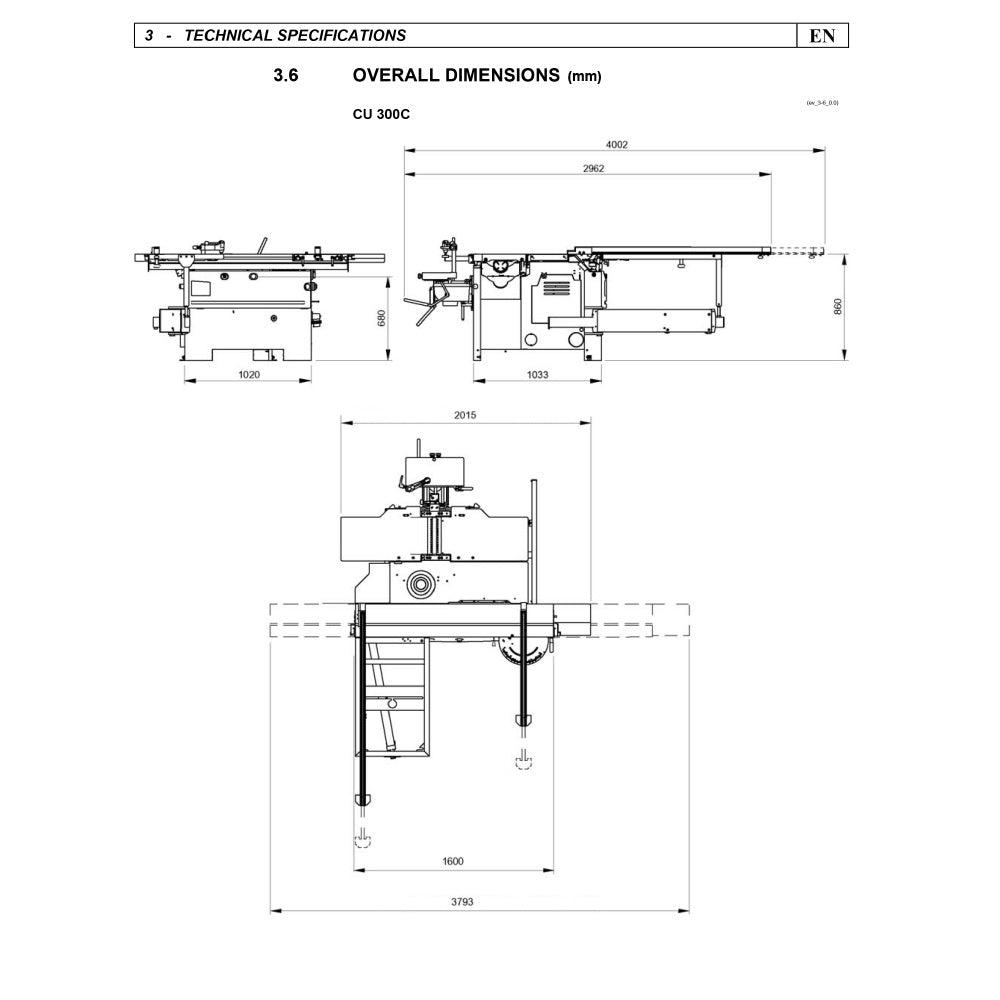

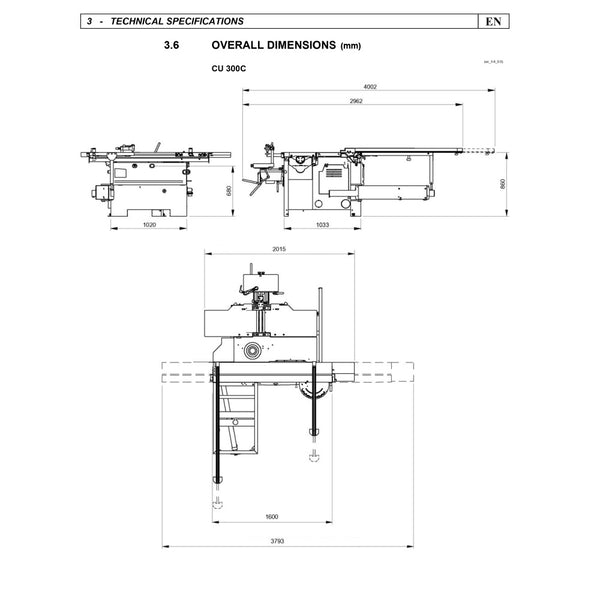

Sliding stroke length: 5.5' (1600 mm)

Max. blade dia. w/ scoring blade in place: 12" x 5/8"

Scoring blade dia.: 80 mm x 20 mm

Max. depth of cut: 3.75"

Rip capacity: 32"

Shaper

Spindle size: 1.25"

Capacity, under-the-nut: 3.5"

Spindle speeds (RPM): 1,700 / 4,000 / 7,000 / 9,000

Max. tooling dia.: Shaping/Tenoning: 8.25" / 10.5625"

Mortiser

Worktable dimensions: 18.5" x 9.1" (470 x 230 mm)

Exhaust hood dia.: 4.7" (120 mm)

Chuck: 0.6" (16 mm)

X stroke: 6.3" (160 mm)

Y stroke: 4.7" (120 mm)

Z stroke: 4.3" (110 mm)

Includes

- (3) Independent 4.8HP (single-phase, 230 V) motors

- (2) Extra handwheels

- Extruded anodized aluminum sliding table on high precision hardened steel guideways

- Squaring frame complete with telescopic fence with 2 crosscut flip-over stops, eccentric clamp, and swinging arm support

- Saw unit with 315 mm max. blade diameter

- 80 mm scoring blade

- Additional table on sliding table

- Miter gauge with flip-over stops

- Adjustable spindle moulder fence with micrometric adjustment complete with vertical and horizontal pressers

- Integrated fence for parallel cuts and surface planing

- Mobility kit

*Shipping

Please note: Items being shipped to extremely remote areas or areas with limited delivery access (such as islands only accessible by ferry) may incur additional shipping or freight fees. If your order requires any additional fees other than what is already included in the price, you will be contacted before those fees are applied and before your item ships. This is rare and will not apply to most orders.

**Machinery Availability Key

Availability statuses found above the product description reflect where a machine is in the supply chain at the time of listing. Use the key below to help determine the lead time for this machine.

In stock for immediate shipment: The machine is in OakTree Supply's warehouse and is ready to ship.

In stock as of [date] / Low stock as of [date]: The machine is in the manufacturer’s U.S. warehouse and was available as of the last update we received. Estimated to ship in 3-5 business days. If low stock, please call us before ordering to confirm current availability.

Estimated to ship [date]: The machine is not yet in our warehouse or the manufacturer’s warehouse. The date shown is an estimate based on current production and shipping timelines and may change due to manufacturing schedules, import processing, or freight transit.

Dates listed as “estimated” are not guaranteed and may change. OakTree Supply is not responsible for delays in transit to or from our facility.