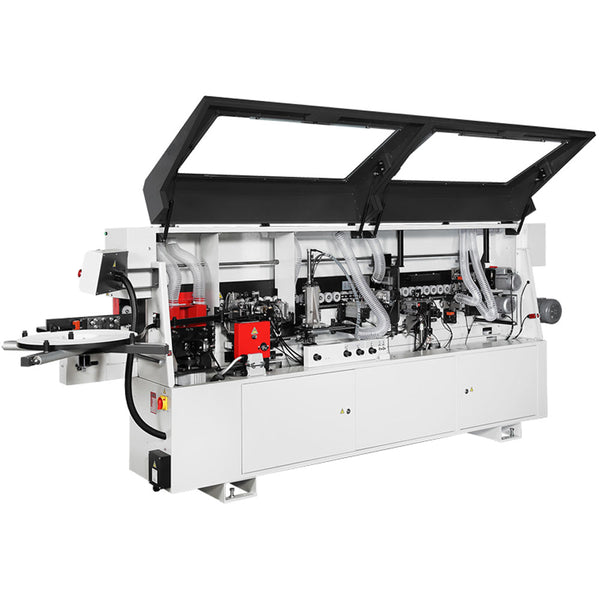

Cantek MX370P (3PH) Automatic Edgebander

- Price

- $ 42,840

Have questions or need help choosing a machine?

Call us at 260-637-0054 or email sales@oaktreesupply.com

Made in Taiwan. Ships from the United States.

Our Easy Purchase Guarantee:

- In stock as of 2.25.26

- Freight included in price.*

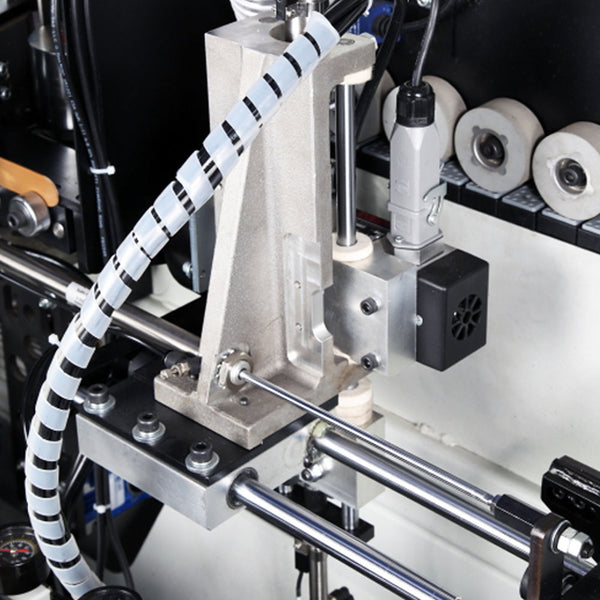

The Cantek MX370P Automatic Edgebander with Premilling and Corner Rounding is designed to be a compact and durable edgebander offered at an affordable price. This machine is equipped with premilling, end trimming, flush trimming, corner rounding, PVC scraping, and buffing. User-friendly controls and adjustments allow for efficient changeovers of edge tape thicknesses between 0.4mm & 3mm.

If you need a quote, we would be happy to provide one. Call 260-637-0054 or email sales@oaktreesupplies.com

Note: Cannot ship to Indiana, Ohio, Pennsylvania or California.

Features

- Versatile edgebander capable of applying 0.4mm to 3mm edge tape.

- Quick change glue pot allows you to change glue colours in minutes.

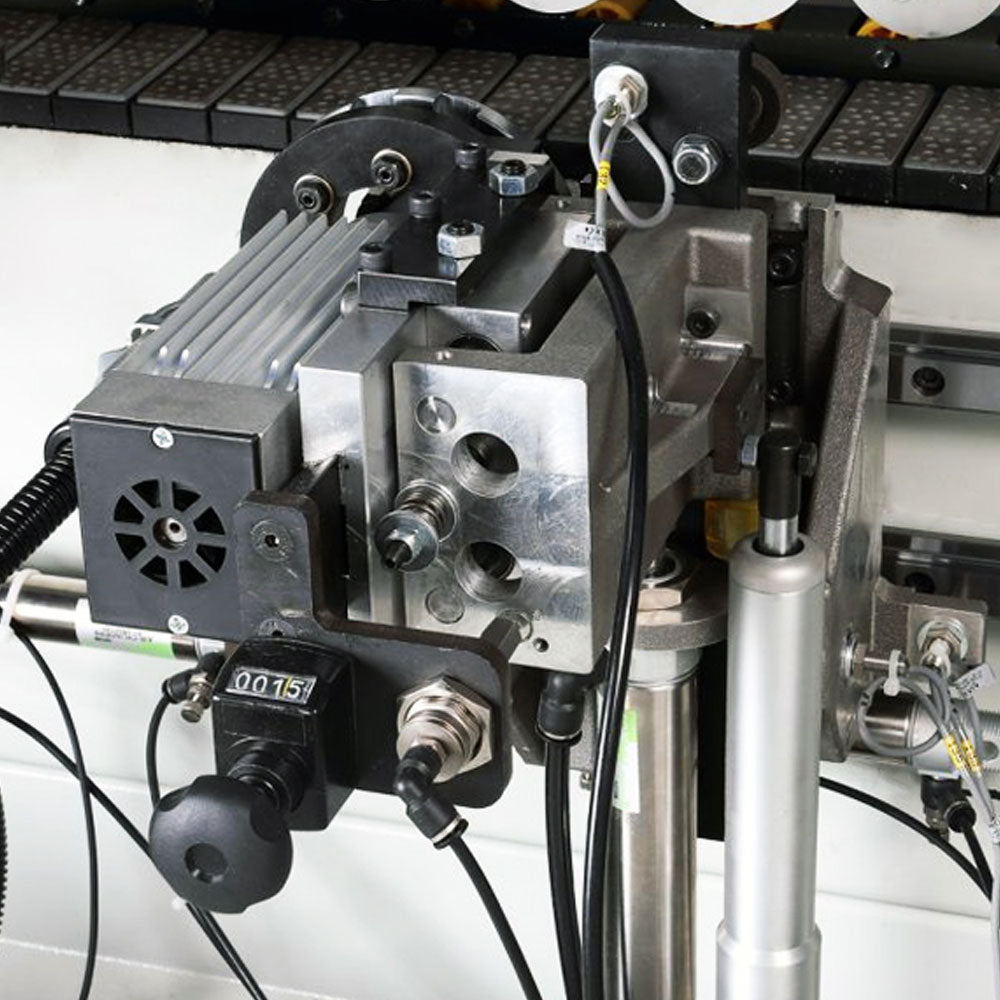

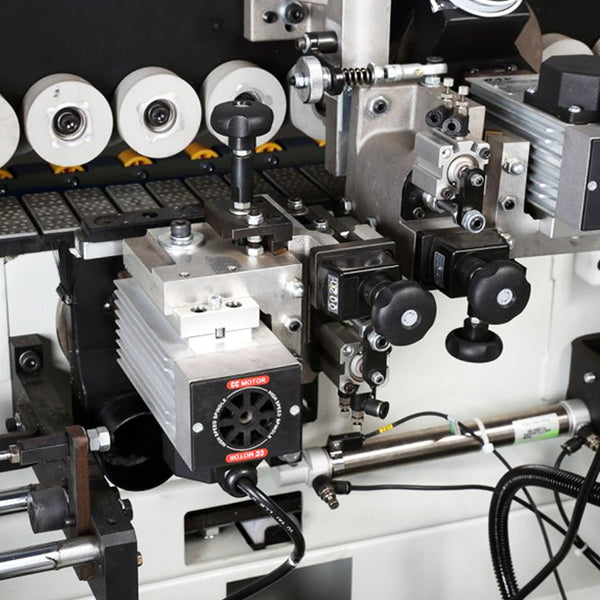

- Premilling ensures a perfectly square edge and clean panel to work with, resulting in a minimally visible glue joint.

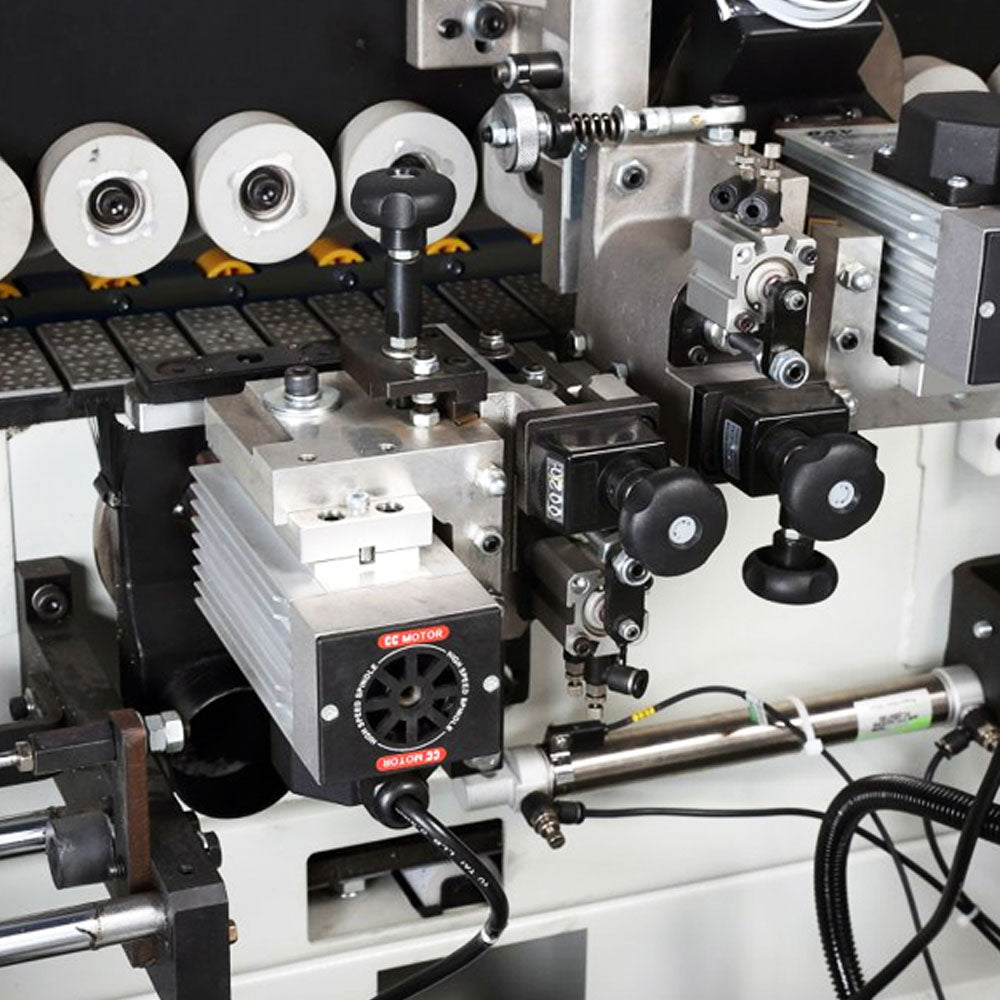

- The corner rounding function finishes the ends of cabinet doors and more with a radius edge, eliminating any manual rework of the panel.

- Automatic edge feeding with a thickness capacity of 0.4–3 mm; strip material can be hand-fed.

- Conveyor chain feed system for reliable results.

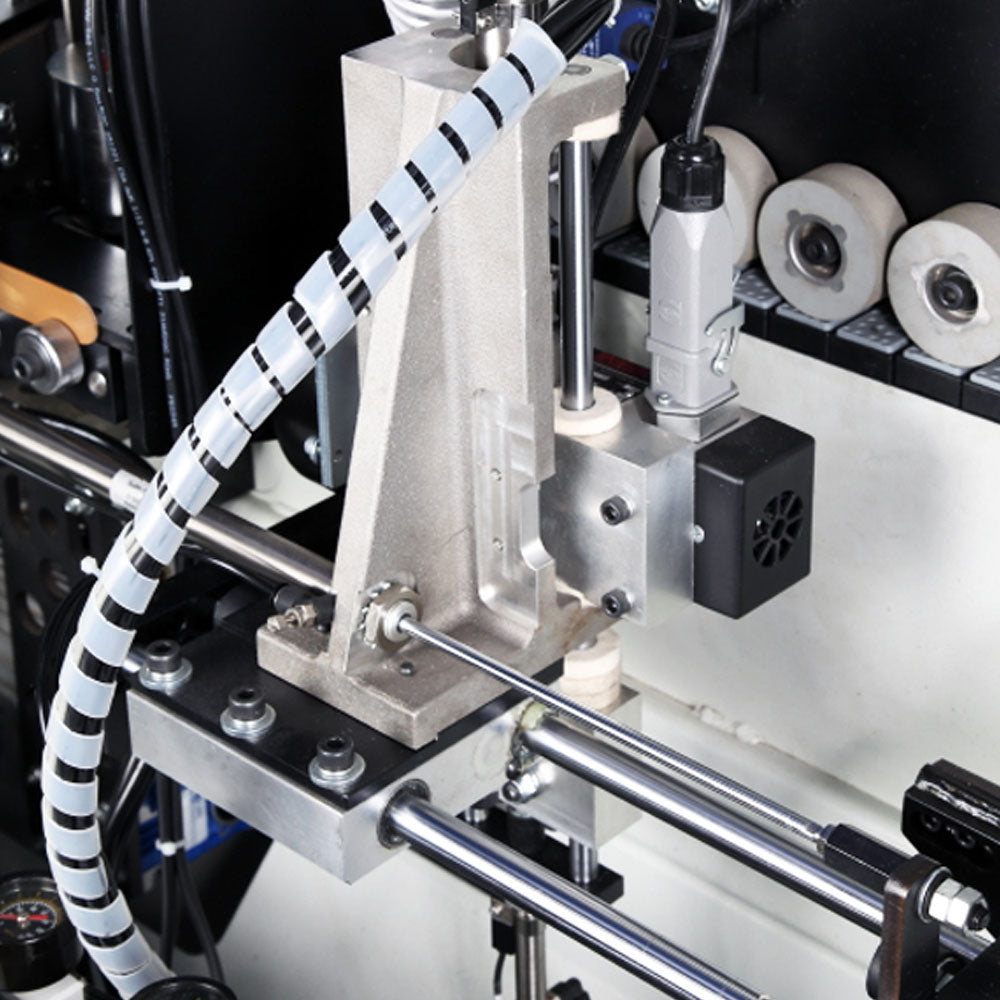

- Teflon-coated hot-melt glue pot.

- Heated infeed fence for pre-heating the panel for optimum glue penetration.

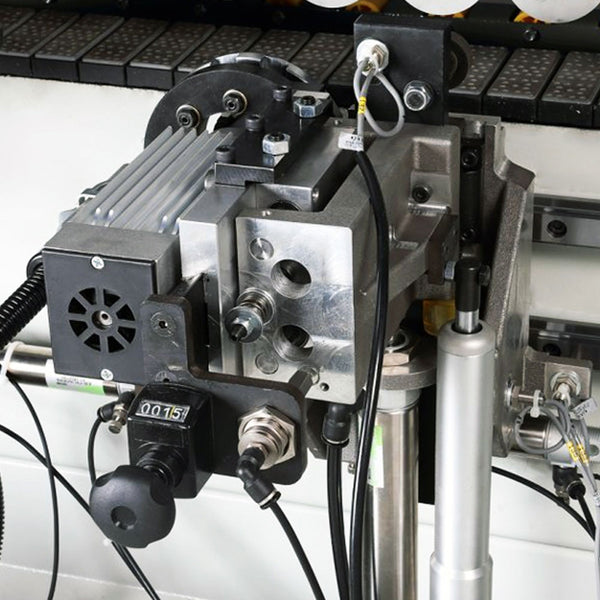

- PLC control system with LED display and keypad.

- Workpiece is fed by chain.

- Edge coil support plate: Ø 800mm (31 ½”), for PVC/ABS.

- Spring-loaded pressure unit with (2) pressure rollers.

- Heavy-duty pressure beam with extendable workpiece support.

Specs

Feeding speed: 29 FPM (9 meters/min.)

Panel thickness: 0.315”~1.77” (8~45 mm)

Edge thickness: 0.0158”~0.118” (0.4 ~ 3 mm)

Min. panel width: 3 ¾” (95 mm)

Min. panel length: 6.7” (170 mm)

Working table height: 38” (960 mm)

Extension support width: 22” (560 mm)

Dust collection outlet: Ø 5” x3 (Ø 127 mm x3)

Electrical consumption: 10.9 HP (6.7 KW)

Electrical: 230/3/60 26 Full load amps

Machine weight: 2024 lbs (910 kgs)

MOTOR SPECIFICATIONS

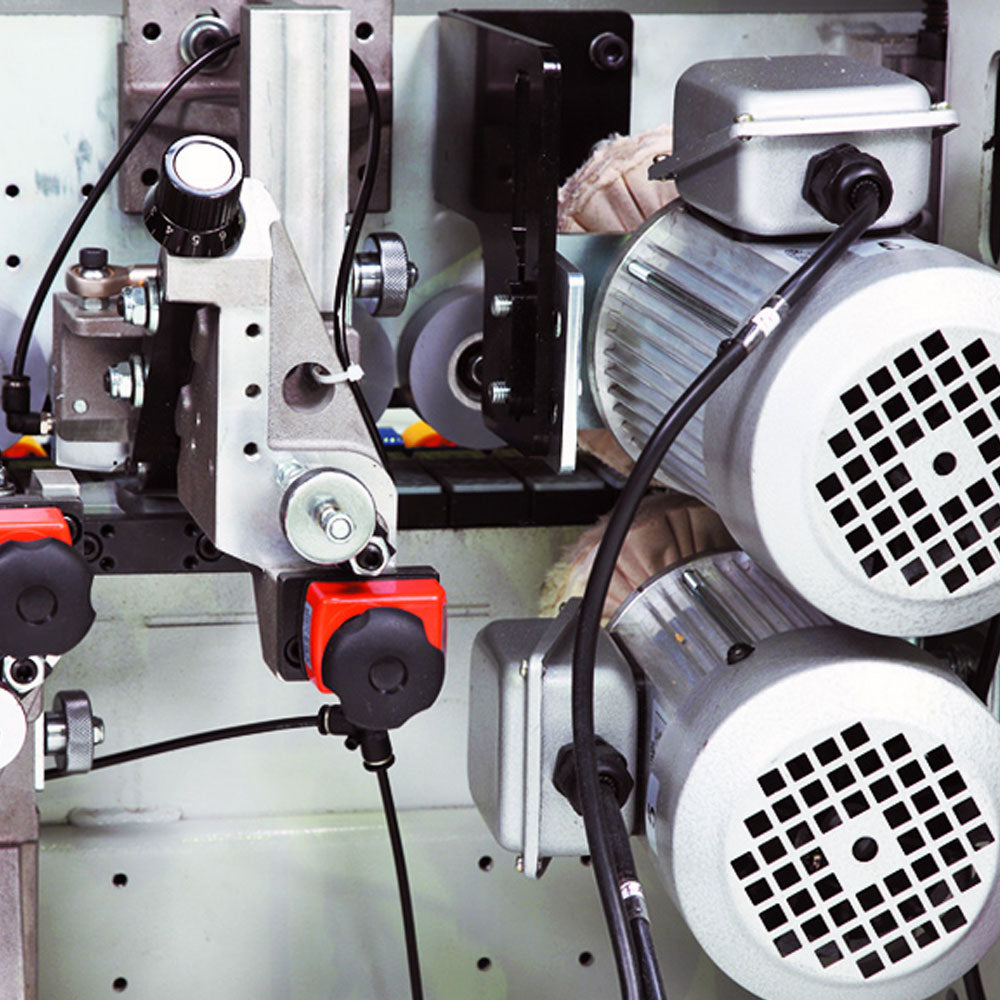

Feeding motor: 1.5 kW

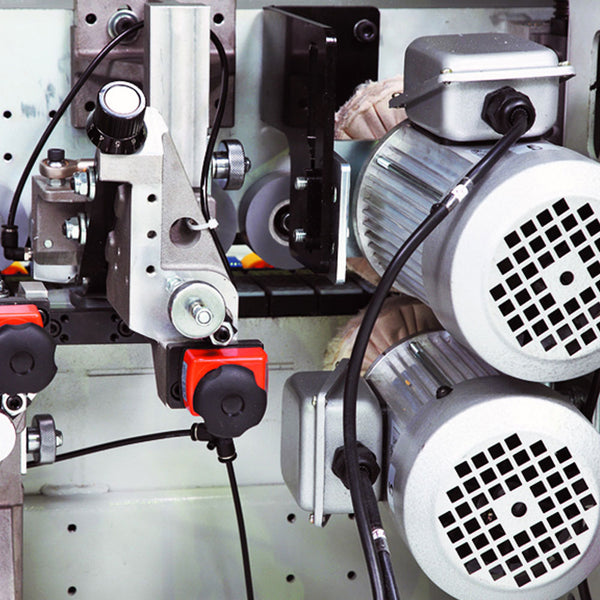

Pre-milling motors (2 pcs): 1.5 kW each (12000 RPM)

Glue spindle motor: 0.25 kW

Front/rear trimming motor: 0.22 kW (12000 RPM)

Upper trimming motor: 0.37 kW (12000 RPM)

Lower trimming motor: 0.37 kW (12000 RPM)

Corner rounding motor: 0.37 kW (12000 RPM)

Upper buffing motor: 0.12 kW (3000 RPM)

Lower buffing motor: 0.12 kW (3000 RPM)

Pre-heating: 0.4 kW

Glue pot: 1.315 kW

Video

*Shipping

Please note: Items being shipped to extremely remote areas or areas with limited delivery access (such as islands only accessible by ferry) may incur additional shipping or freight fees. If your order requires any additional fees other than what is already included in the price, you will be contacted before those fees are applied and before your item ships. This is rare and will not apply to most orders.