Cantek MX350 (3PH) Automatic Edgebander

- Price

- $ 35,595

Have questions or need help choosing a machine?

Call us at 260-637-0054 or email sales@oaktreesupply.com

Made in Taiwan. Ships from the United States.

Our Easy Purchase Guarantee:

- In stock as of 2.25.26

- Freight included in price.*

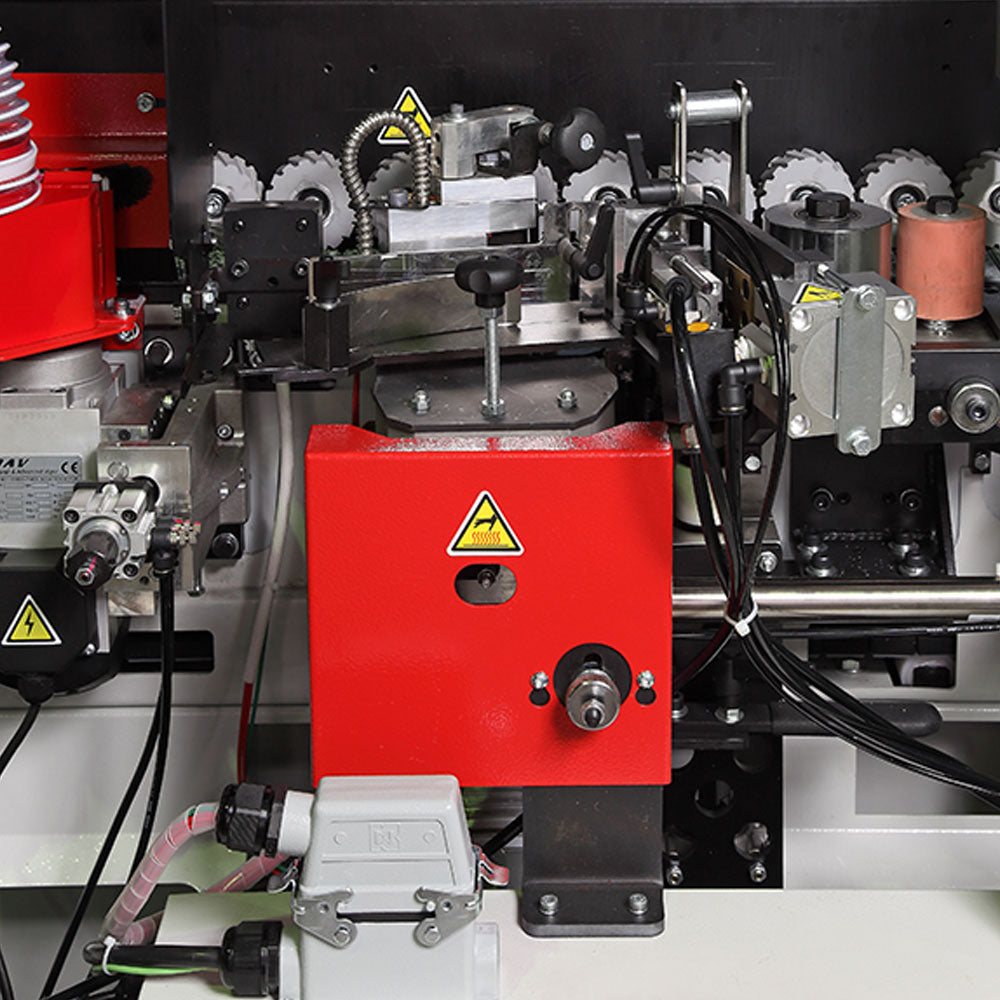

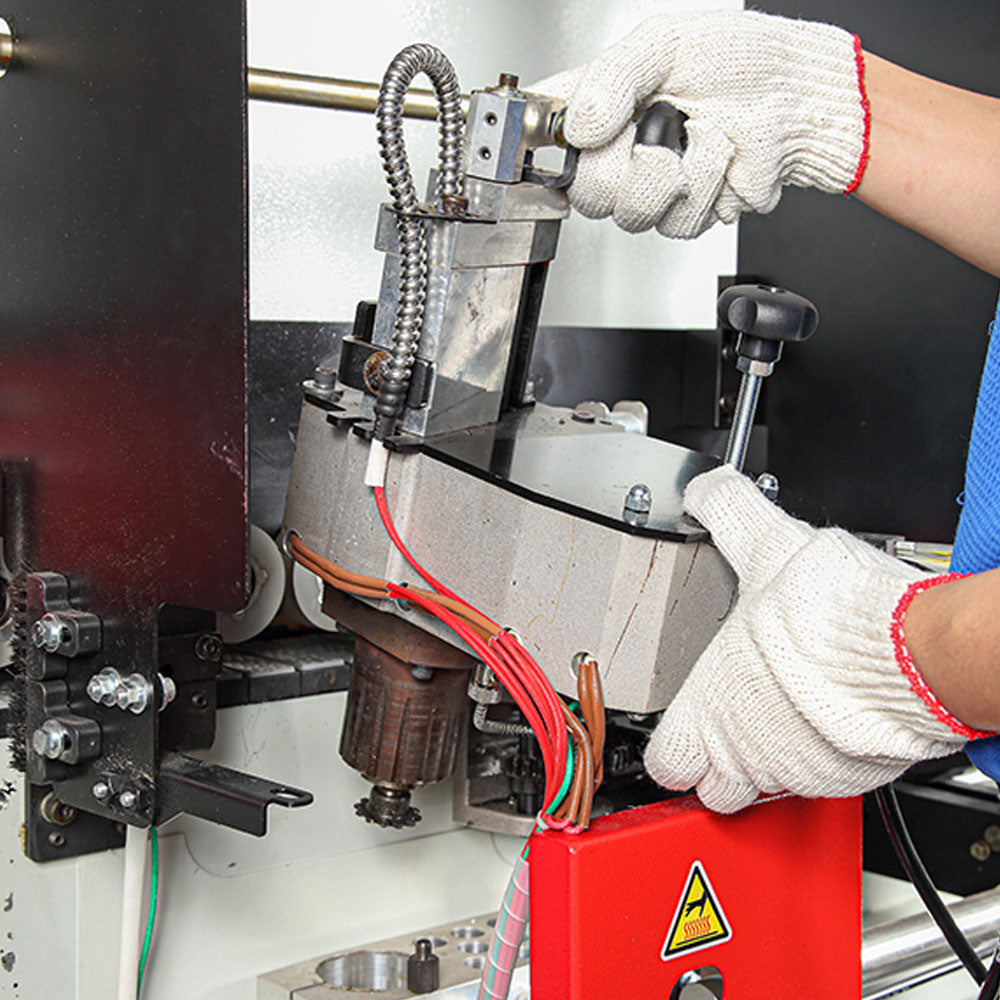

The Cantek MX350 Automatic Edgebander is a compact edgebander capable of applying up to 3mm thick edge tape on cabinet parts and more. The counter rotating pre-milling cutters ensure optimum panel edge quality and squareness which result in a less visible glue joint.

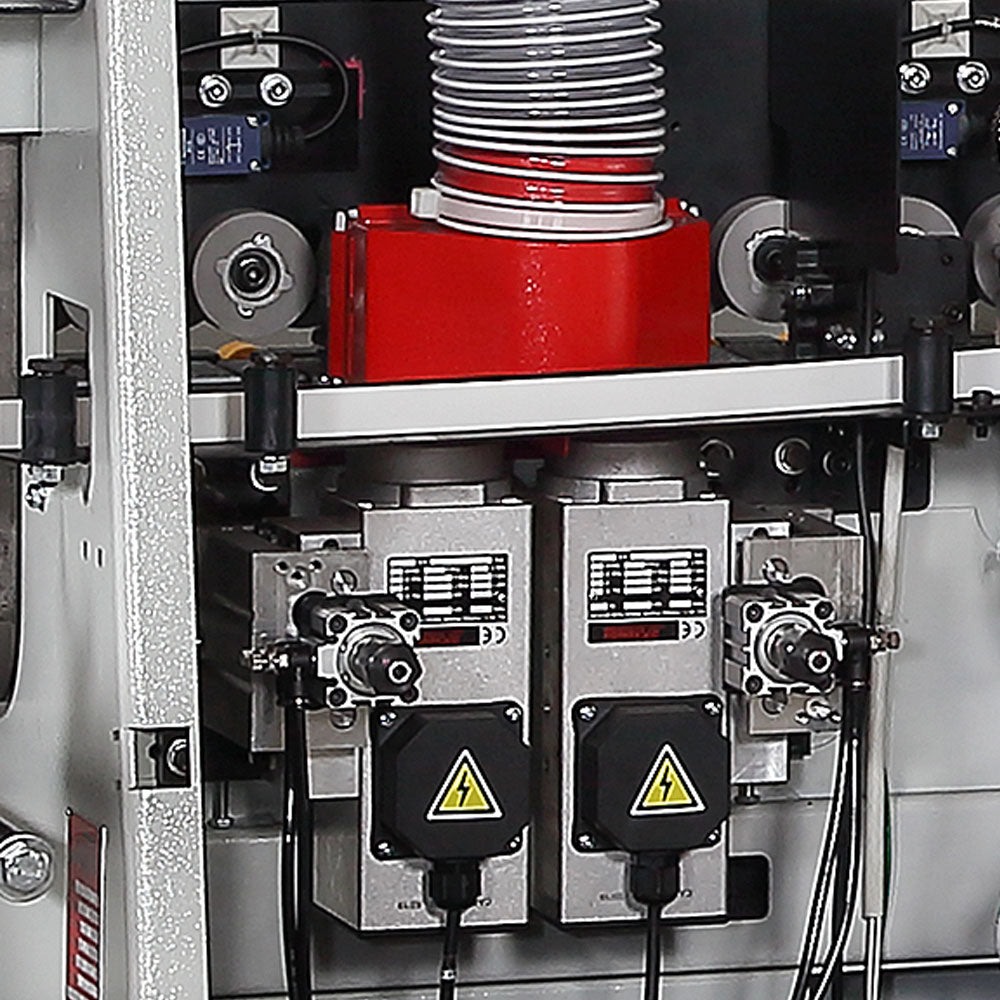

It comes equipped with high frequency motors on both the end trim and top & bottom trim. In addition it is equipped with PVC radius scraping and buffing units. User friendly controls and adjustments allow for efficient changeovers of edge tape thicknesses between 0.4mm & 3mm. It’s compact design and affordable price point make it the ideal edge banding solution for the small cabinet shop who requires pre-milling.

If you need a quote, we would be happy to provide one. Call 260-637-0054 or email sales@oaktreesupplies.com

Note: Cannot ship to Indiana, Ohio, Pennsylvania or California.

Features

- Versatile edgebander capable of applying 0.4mm to 3mm edge tape.

- Quick change glue pot allows you to change glue colours in minutes.

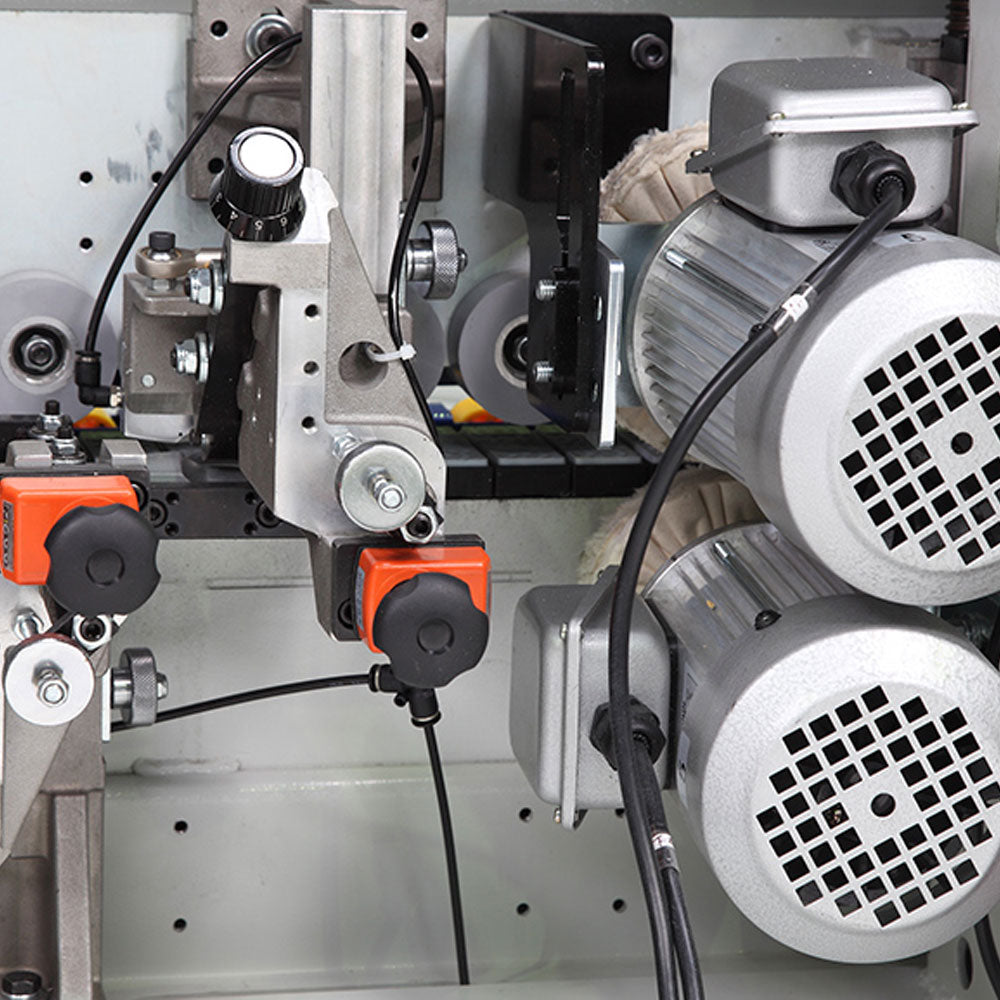

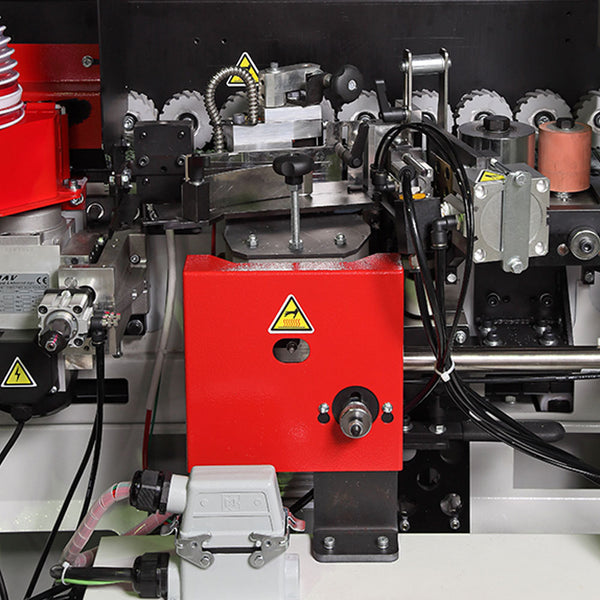

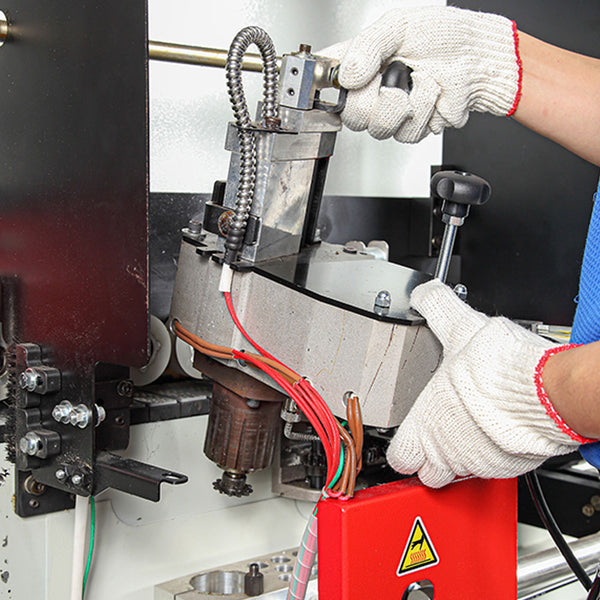

- Couter rotating diamond premilling cutters produce optimum panel edge for superior edgebanding results

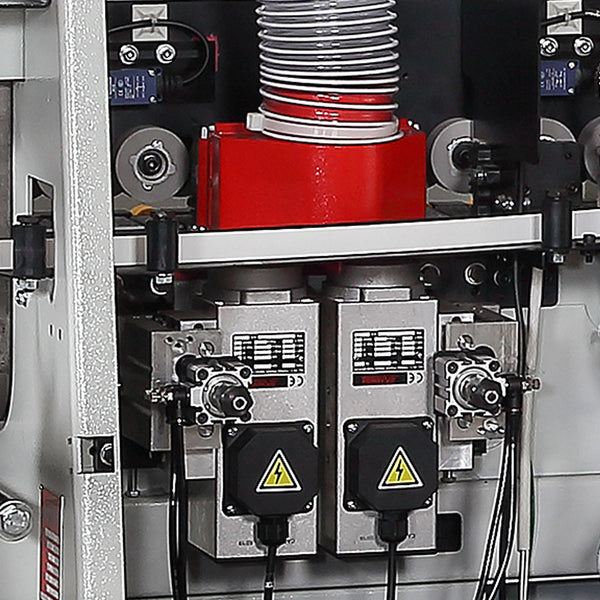

- High frequency end trim & flush trim motors produce fine edge finishing results

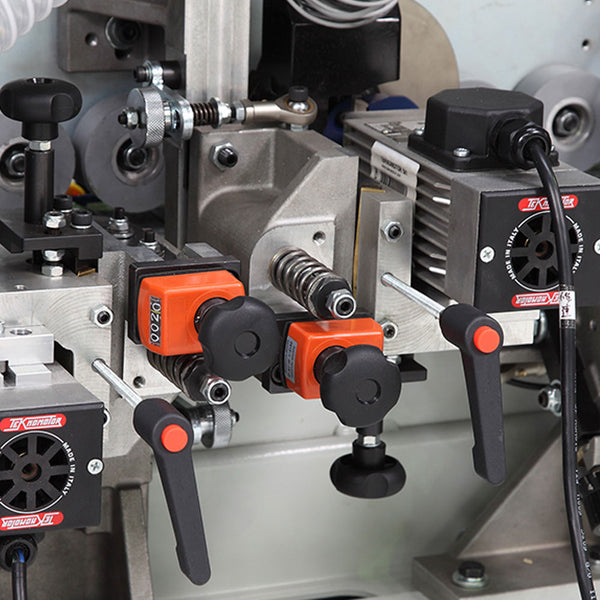

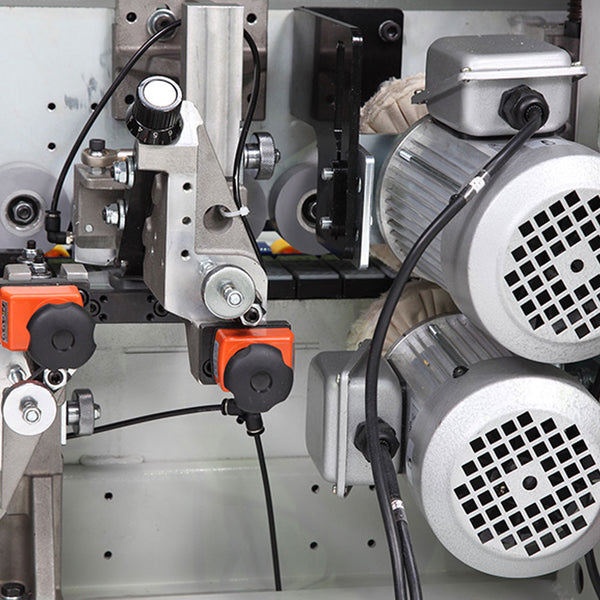

- Multi-function trimmers allows for flush or radius trimming on edge banding

- Radius scraping removes any knife marks on radius edges

- Buffing unit polishes the edge

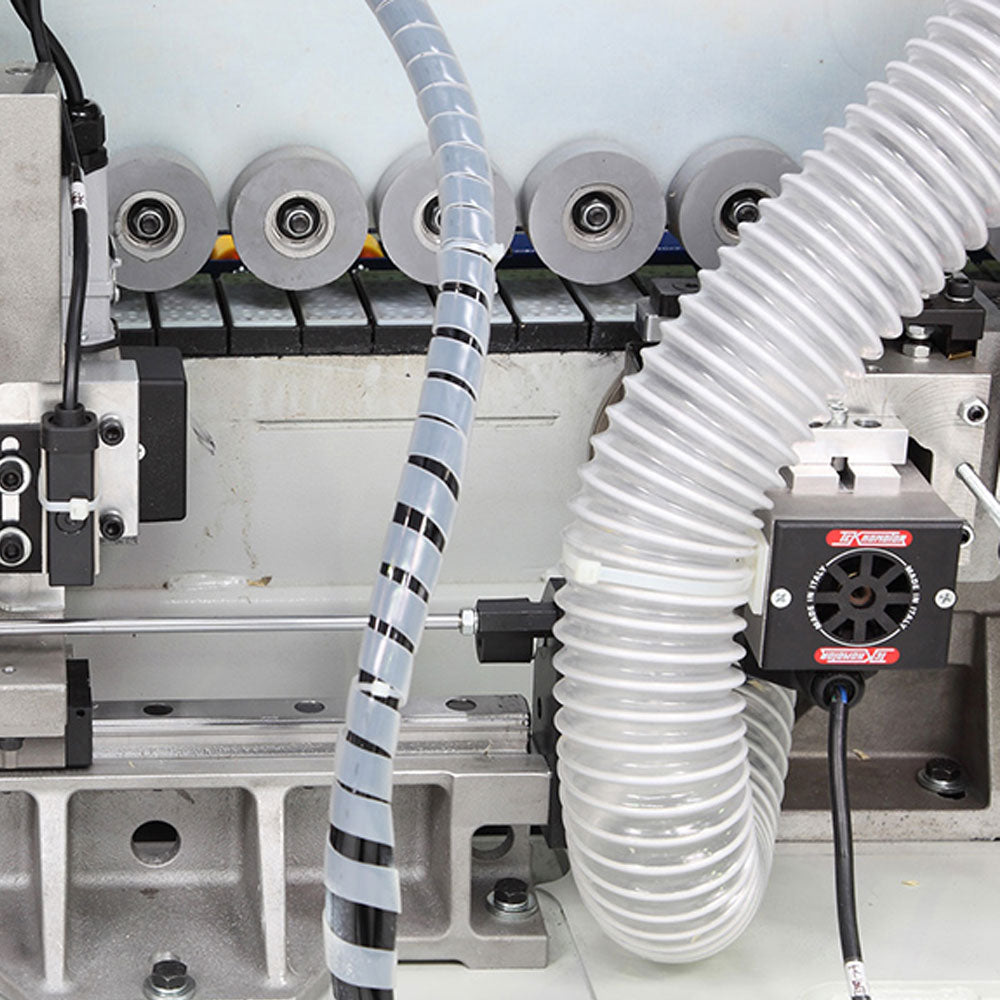

- Powerful chain feed system ensure work piece stability during application and processing of edge banding resulting in a high quality finish

- Teflon coated Quick Change glue pot can be removed and exchanged in only minutes. Comes with (1) quick change pot and others can be acquired for running different color glues.

- Automatic edge feeding with a thickness capacity of 0.4–3 mm; strip material can be hand-fed

- Conveyor chain feed system for reliable results

- Heated infeed fence for pre-heating the panel for optimum glue penetration

- PLC control system with LED display and keypad

- Workpiece is fed by chain

- Edge coil support plate: Ø 800mm (31 ½”), for PVC/ABS

- Spring-loaded pressure unit with (2) pressure rollers

- Heavy-duty pressure beam with extendable workpiece support

Specs

Feeding speed: 29 FPM (9 meters/min.)

Panel thickness: 0.315”~1.77” (8~45 mm)

Max. pre-milling thickness: 1.77” (45mm)

Edge thickness: 0.0158”~0.118” (0.4 ~ 3 mm)

Min. panel width: 4” (100 mm)

Min. panel length: 6.7” (170 mm)

Working table height: 33.5” (850 mm)

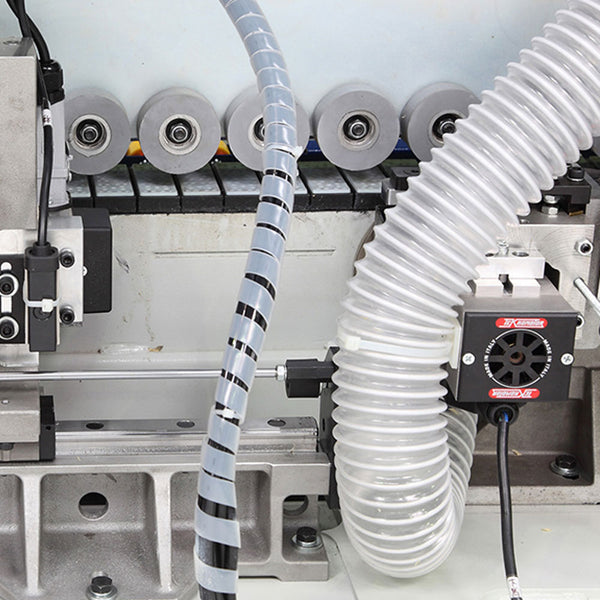

Dust collection outlet: Ø 5” x 3 (Ø 127 mm x 3)

Total connected power: 10 HP (7.5 kW)

Machine dimensions (LxWxH): 147” x 52” x 54” (3700 x 1310 x 1380mm)

Machine weight: 1452 lbs (660 kgs)

Shipping dimensions (LxWxH): 91” x 29” x 54” (2290 x 720 x 1370mm)

Shipping weight: 1558 lbs (708 kgs)

Electrical requirement: 230/3/60: 40 amps

*Shipping

Please note: Items being shipped to extremely remote areas or areas with limited delivery access (such as islands only accessible by ferry) may incur additional shipping or freight fees. If your order requires any additional fees other than what is already included in the price, you will be contacted before those fees are applied and before your item ships. This is rare and will not apply to most orders.