Cantek GT610HI 24" Cardan Shaft Drive Double Surfacer Planer

- Price

- $ 77,175

Have questions or need help choosing a machine?

Call us at 260-637-0054 or email sales@oaktreesupply.com

Made in Taiwan. Ships from the United States.

Our Easy Purchase Guarantee:

- Please call for availability.

- Freight included in price.*

The Cantek GT610HI Cardan Shaft Drive Double Surface Planer is capable of speeds up to 98 feet per minute and its robust cast-iron body & industrial Cardan drive system ensure high production planing day in and day out. The large-diameter cutter heads are the spiral type with two-sided solid carbide inserts which produce a clean finish with superior stock removal capacity.

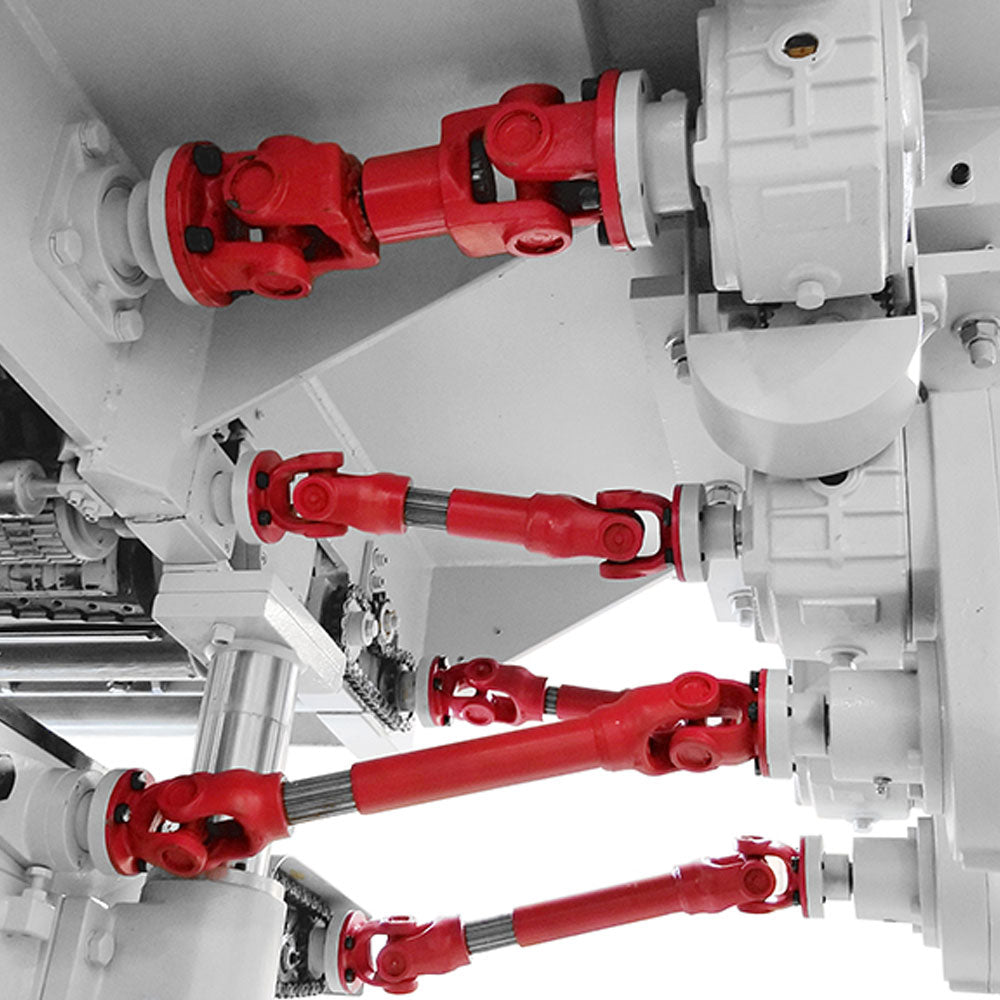

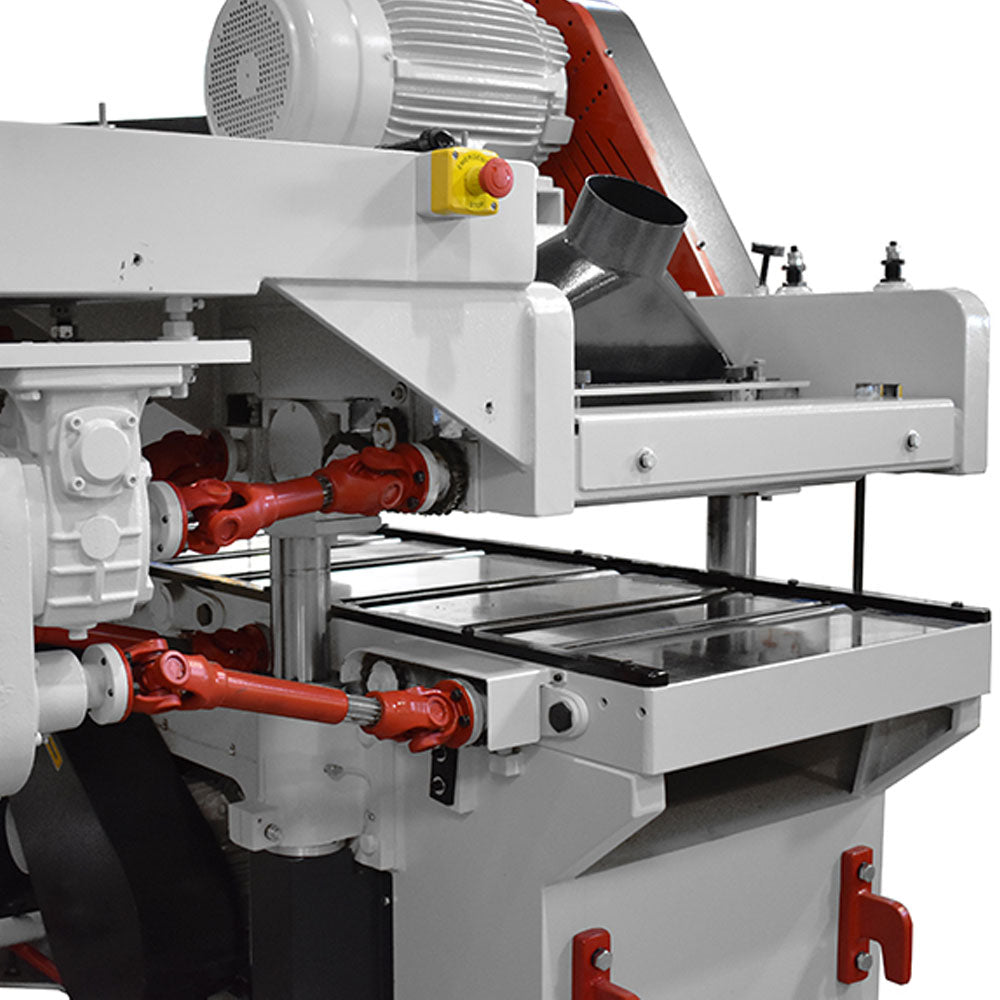

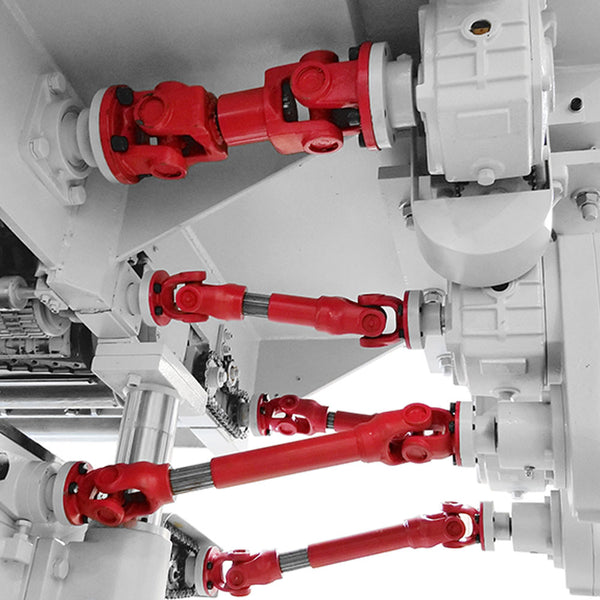

The powerful Cardan shaft drive system provides maximum feeding power with higher capacity feed rates. The Cardan system drives the top conveyor, (3) bed rollers, the top sectional feed roller, and smooth outfeed rolls. The spring-loaded feed system passes the material over the bottom head allowing it to act like a jointer to flatten the board prior and then a sectional infeed roller feeds the material through the top head for accurate dimensioning.

Experience the convenience of an operator control panel with digital thickness control (mm/inch), individual amp meters for cutterheads and feed, digital speed display, hour meter, and emergency shut off. The thickness can be programmable in 0.001"/ 0.01mm resolution, adding the highest precision to your thickness operation.

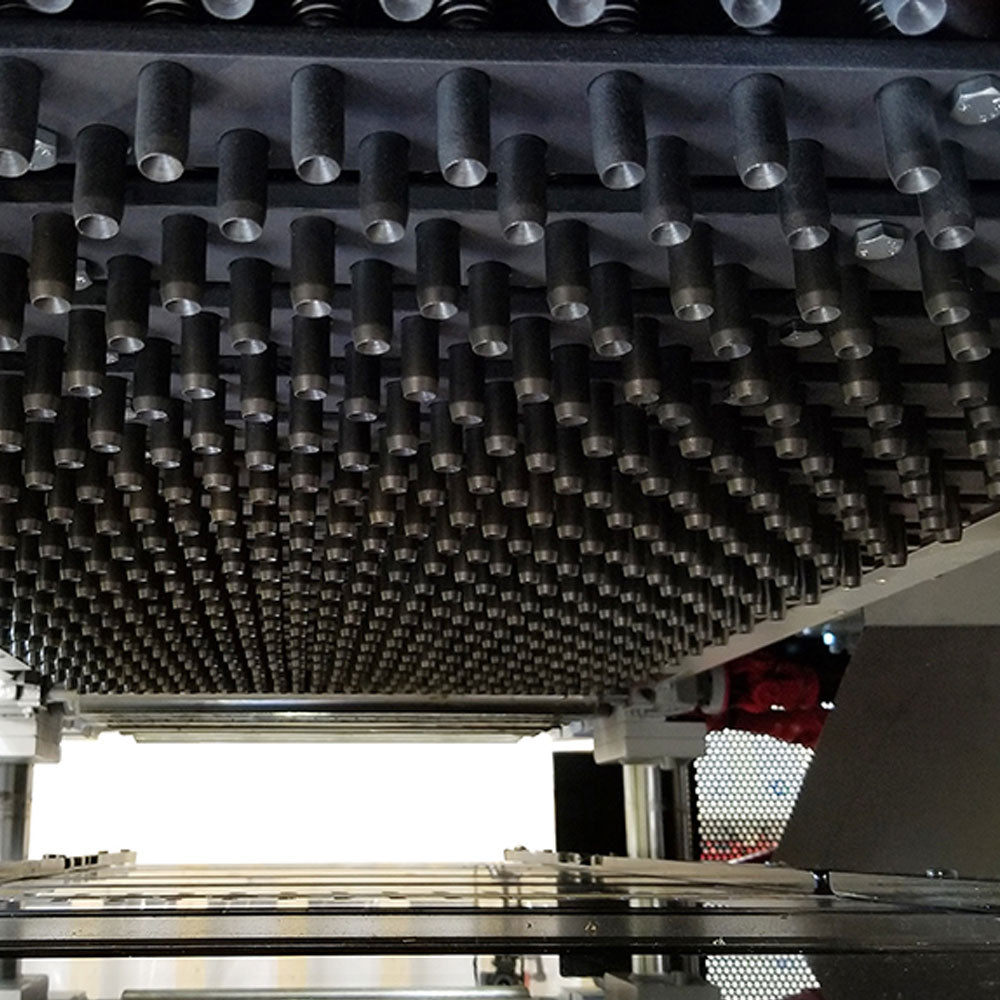

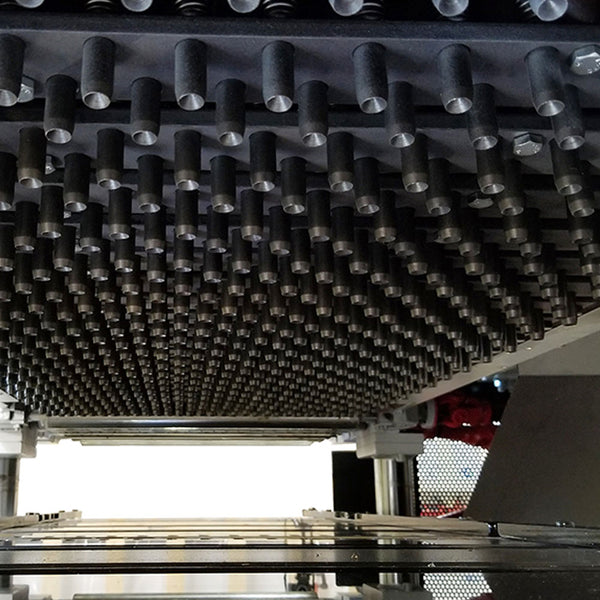

This machine comes equipped with top and bottom insert knife cutterheads with standard 2-sided reversible knives (105 knives for each cutterhead). They are oriented in a spiral pattern to reduce load, noise and provide optimum finishing results. This system allows for maximum stock removal due to the type of knife and the way it sits in the cutterhead.

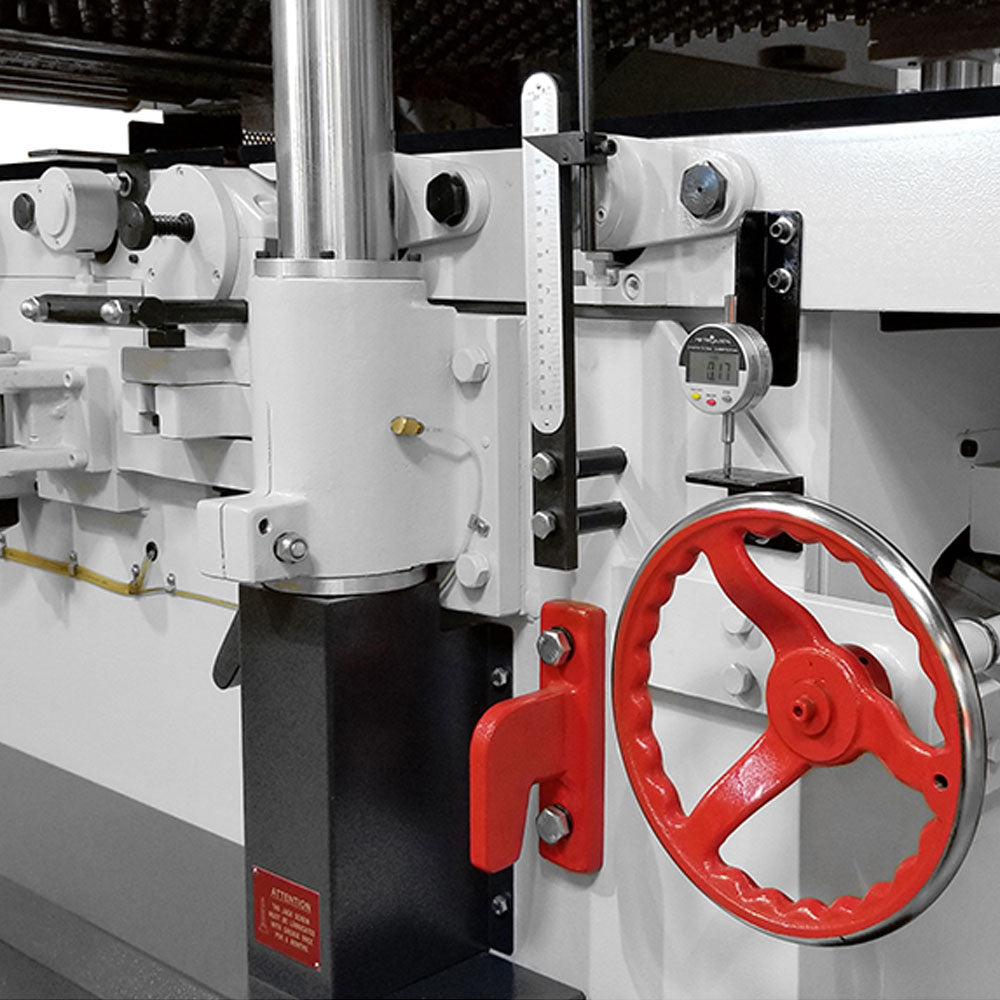

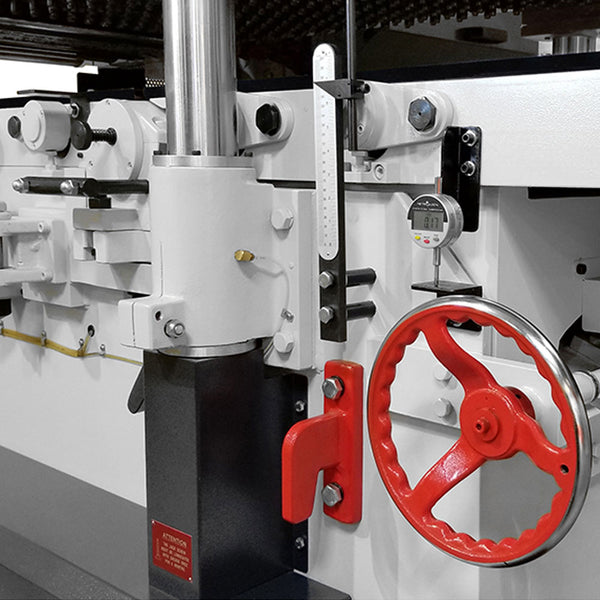

The bottom cutterhead, as well as the top dust hood, can be quickly removed from the machine to facilitate convenient knife changes. The bearings are a precision ABEC 7 RHP bearing known for its high precision and long wear life. The infeed bed is adjustable to set the desired stock removal from the bottom head. The height is indicated using a dial indicator.

If you need a quote, we would be happy to provide one. Call 260-637-0054 or email sales@oaktreesupplies.com

Note: Cannot ship to Pennsylvania or California.

Features

- Powerful 40hp top head motor and 30hp bottom head motor for maximum stock removal

- Full Cardan shaft feed system allowing for faster feed speeds up to 98 FPM

- Planing capacity up to 24” wide and 8” thick

- Pin type carpet feed system passes the material over the bottom head to ensure a flat surface

- (7) bed rollers including (3) driven rolls for superior feed speeds

- Spiral insert knife cutterheads with 6 rows of two-sided 30x12x2.5mm solid carbide insert knives provide superior stock removal, reduced machine load and noise, and optimum finish quality

- Automatic lubrication to the conveyor feed system

- Cast iron machine frame for superior vibration damping resulting in a long machine & bearing life

- Chrome-plated tables and top and bottom for maximum wear resistance

- Cutterheads are mounted in precision ABEC 7 RHP bearings

- Feed system uses a spring loaded pin arrangement to pass material over the bottom jointing head

- Sectional serrated infeed roll before the top cutterhead

- Variable feed speed by frequency inverter (VFD) with digital display for the feed speed

- Digital thickness control for quickly and precisely setting the desired thickness

- Upper assembly is adjusted for desired thickness by four large-diameter cylindrical posts

- Adjustable infeed bed by easily accessible handwheel to set desired stock removal on the bottom head

- Easy to access swivel control panel with individual ammeters for load monitoring and hour meter to aid in maintenance planning

- Cutterhead starters are Y-Delta providing soft start to the heads for reduced power consumption on startup

- (2) 6" dust ports for efficient dust collection for the top and bottom heads

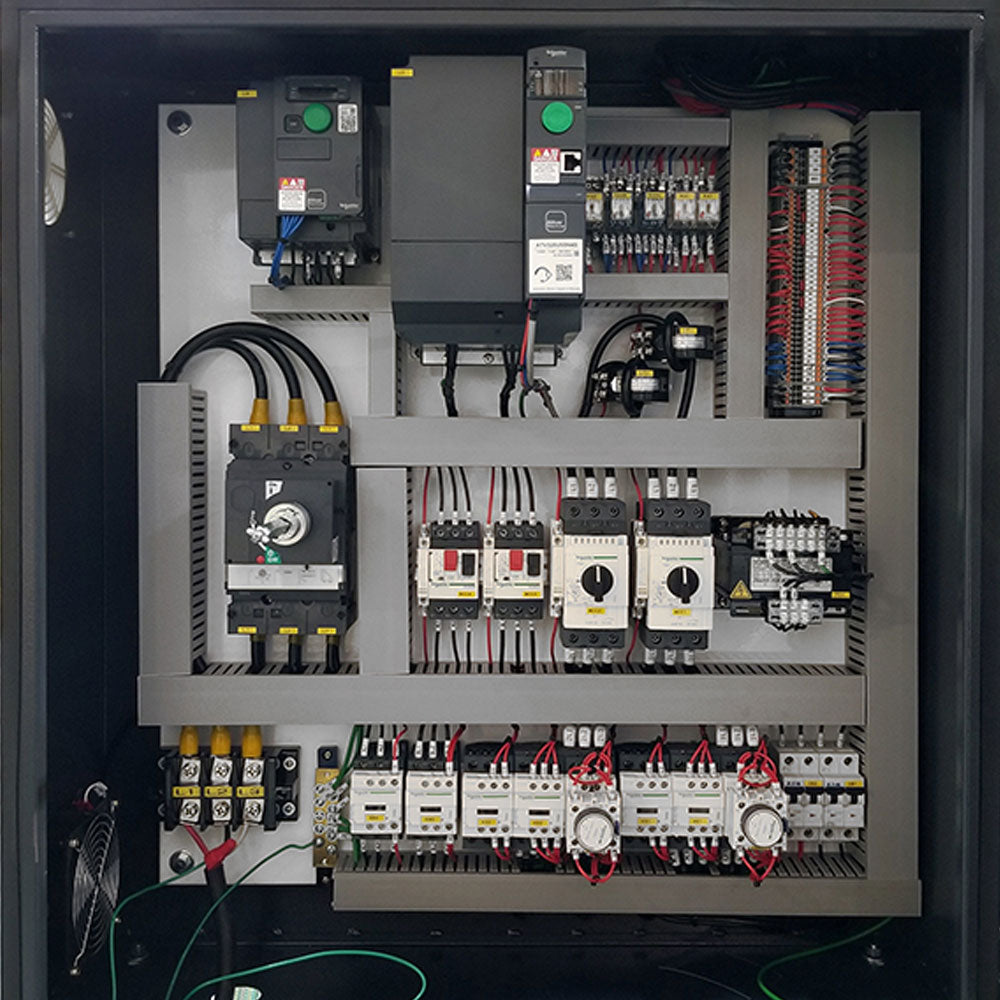

- High-quality Schneider electrical components to CSA/UL standard

- Equipped with safety covers for the shaft drive system to allow for safe machine operation

Specs

Max. working width: 24” (610 mm)

Max. working thickness: 8” (200 mm)

Min. working thickness: 5/16″ (8 mm)

Min. working length: 12” (300 mm)

Cutterhead RPM: 5,000 RPM

Cutterhead diameter: 5.3” (135 mm)

Feed speed: 30-98 FPM (10 – 30 m/min)

Top cutterhead motor: 40hp

Bottom cutterhead motor: 30hp

Feed motor: 5hp

Table Rolls: 7 (3) driven

Opening hoist motor: 1hp

Machine weight: 8,800 lbs.

Machine dimensions (L x W x H): 112” x 67” x 67”

Shipping weight: 9,240 lbs.

Shipping dimensions (L x W x H): 115” x 75” x 75”

Video

*Shipping

Please note: Items being shipped to extremely remote areas or areas with limited delivery access (such as islands only accessible by ferry) may incur additional shipping or freight fees. If your order requires any additional fees other than what is already included in the price, you will be contacted before those fees are applied and before your item ships. This is rare and will not apply to most orders.