Cantek C12RSH 12" Glue Line Ripsaw (230V/460V)

- Price

- $ 22,785

Have questions or need help choosing a machine?

Call us at 260-637-0054 or email sales@oaktreesupply.com

Made in Taiwan. Ships from the United States.

Our Easy Purchase Guarantee:

- In stock as of 2.25.26.

- Freight included in price.*

Save time and speed up production in your glue-up and ripping operations.

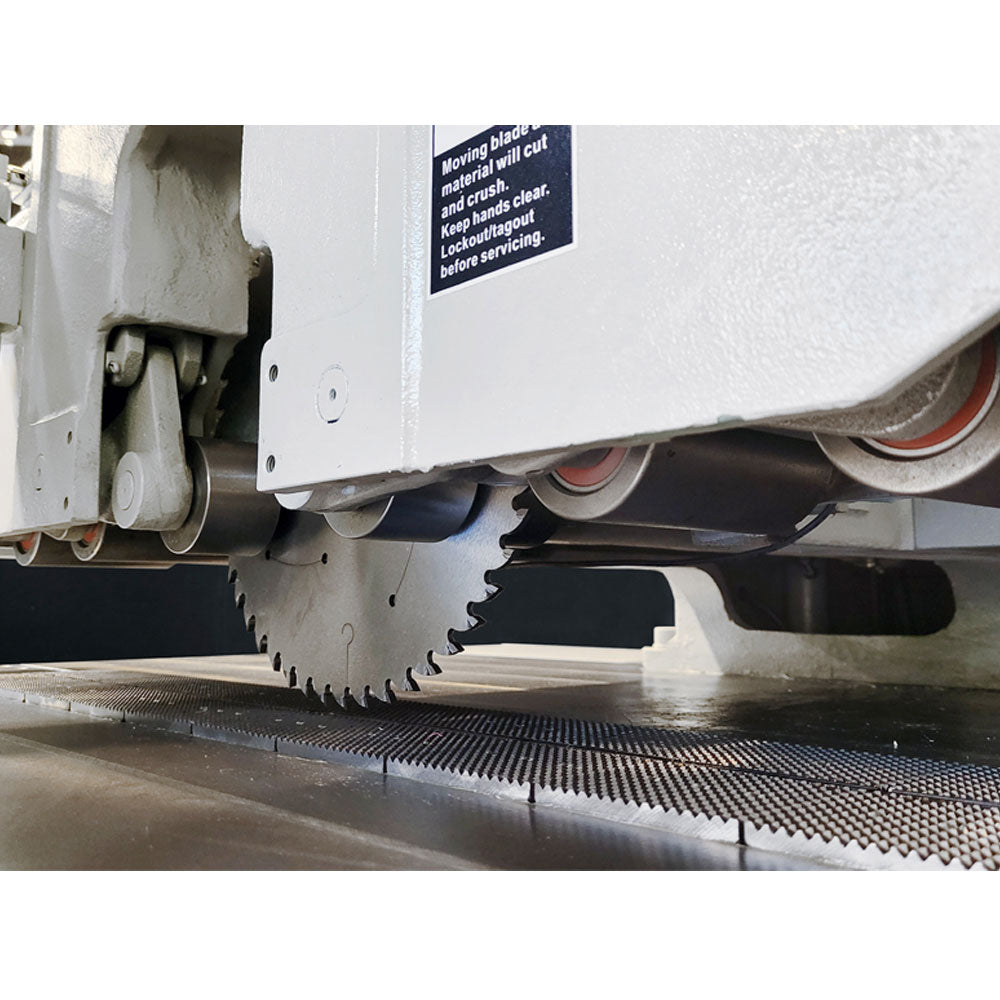

The Cantek C12RSH Straight Line Glue Joint Ripsaw is a single-blade ripsaw geared towards the shop looking to increase efficiency in their ripping operations but can not justify a multi-blade ripsaw. With its precision cast iron chain and track assembly, and extended pressure section, the C12RSH can produce a glue joint finish ready for panel glue-up right out of the saw.

The machine table is made of heavy-duty cast iron, and the saw head assembly has superior vibration damping for optimum cut quality and wear resistance. The table is precision machined to ensure consistency through any operation. Double-V FC35 high-grade cast-iron chain pads to ensure long life and optimum precision.

The chain track assembly is also made from FC35 high-grade cast iron and has a double V-pattern to ensure absolute precision straight line cutting. Each rail has oil lubrication points so that constant and consistent lubrication is applied for superior wear resistance.

Never have to oil your machine’s chains yourself again! This machine features automatic mechanical chain lubrication. Lubricant flow rate can be adjusted automatically with the caterpillar chain feed speed variation. Plus, when lubrication runs out, the chain stops automatically, preventing damage to the machine.

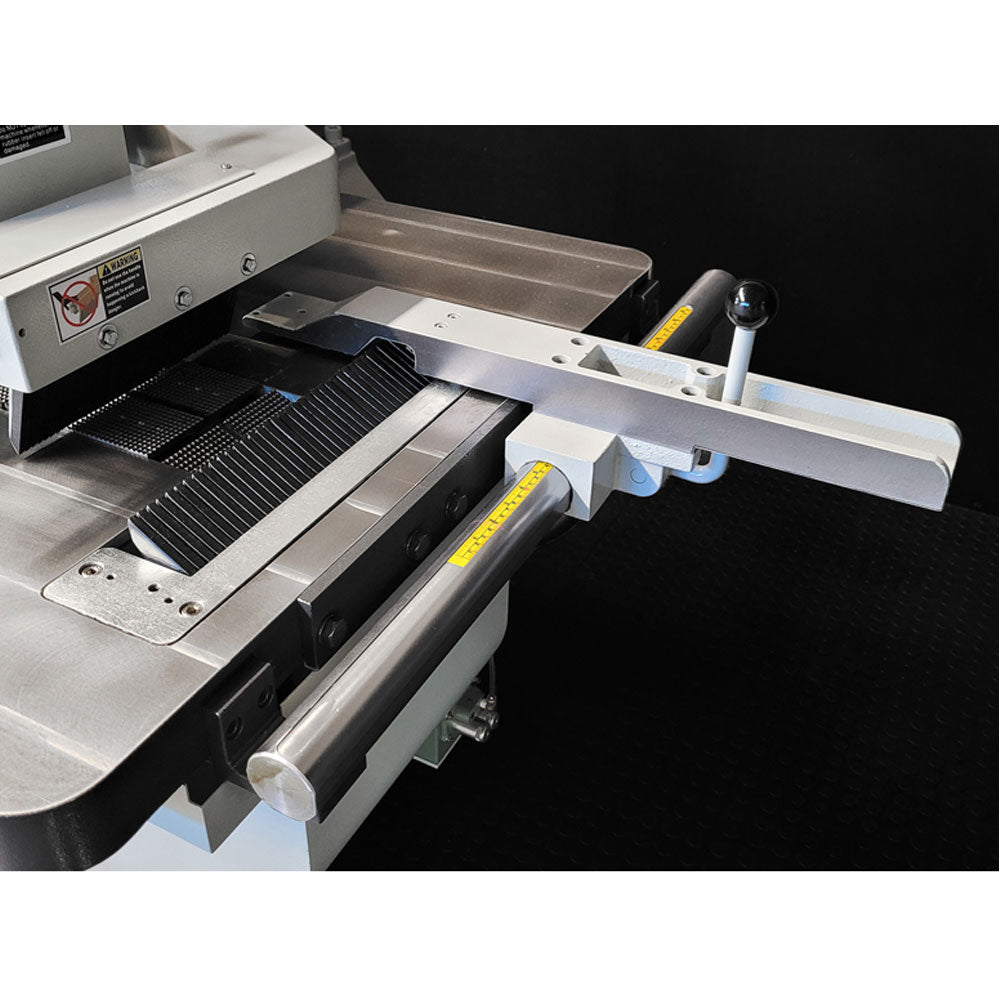

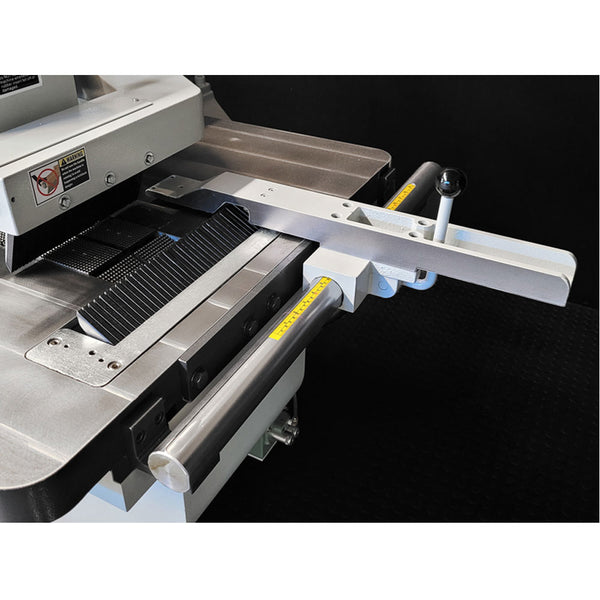

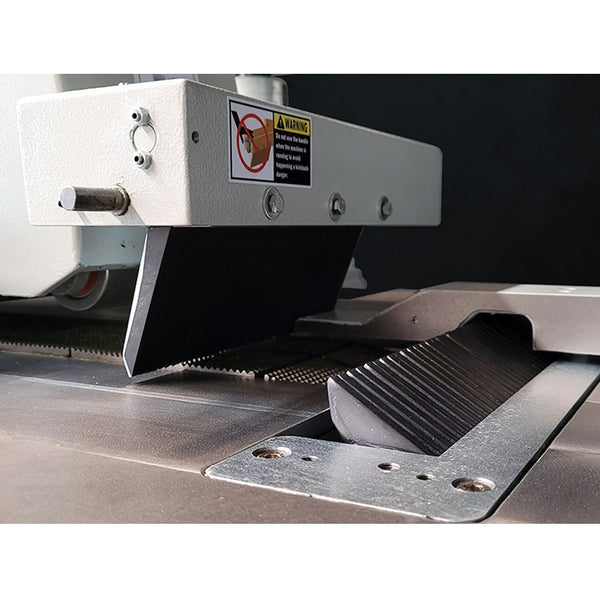

Quick setting rip fence runs on a round cylindrical guide. A ruler scale will indicate the fence position and is quickly set in place using a locking lever. The fence is outfitted with a bearing on the bottom side for ease of travel. Fence is notched to pass over and under the table and top kickback fingers for faster change over.

Please note: Due to rebranding, images of machine features may differ in color. All features listed are still included with the machine.

If you need a quote, we would be happy to provide one. Call 260-637-0054 or email sales@oaktreesupplies.com

Note: Cannot ship to Indiana, Ohio, Pennsylvania or California.

Features

- Produces a guaranteed glue joint finish to 10′, which eliminates the need to joint the material after ripping

- Precision straight-line feeding for parallel and accurate rip cuts

- Eight hold-down rollers over six rows ensure material is firmly held during cutting operations for a longer period resulting in a straighter, more precise cut

- Mechanical operation Chain Oiler provides consistent lubrication to the chain track and automatically adjusts to your feed speed

- When oil runs low, a warning light will come on, and when it gets too low, the machine track stops running to avoid damage to the track

- Operator can conveniently adjust the feed speeds of the machine, ranging from 50 to 120 FPM

- Cast iron saw assembly, column, and table with superior vibration damping properties for optimum cutting results while ensuring long bearing and machine life

- Rigid machine body consists of a thick welded steel frame

- FC35 cast iron chain track with double-V design ensures precision straight-line ripping with a long wear life

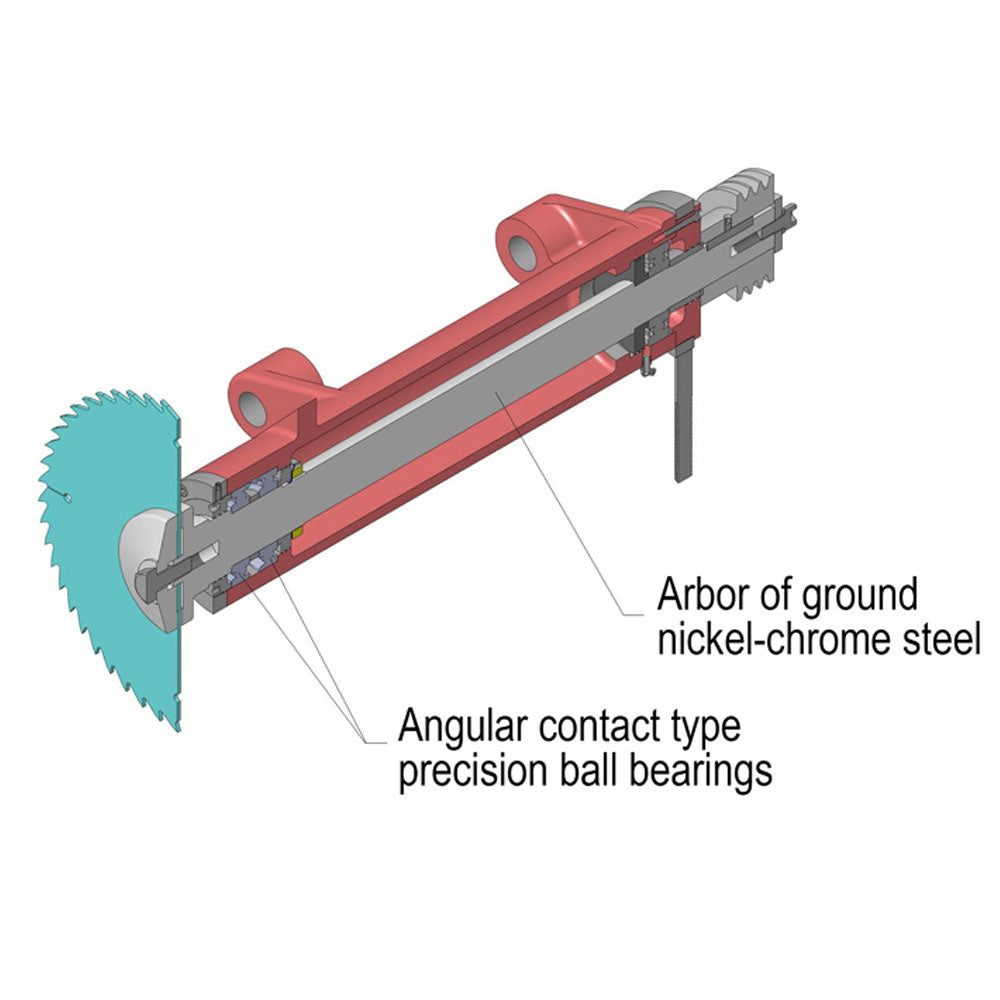

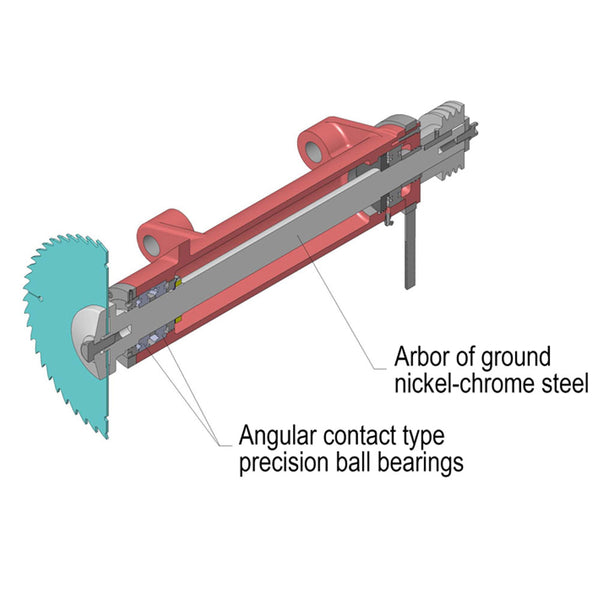

- Precision Built Saw Arbor constructed of nickel-chrome steel, large diameter, accurately ground and dynamically balanced

- Arbor runs in precision angular contact type ball bearings (eliminates any radial run-out & axial thrust) – V Belt driven from below

- Cast iron rip fence is mounted to a large diameter round guide rail with a quick-locking lever for effortless and accurate adjustment

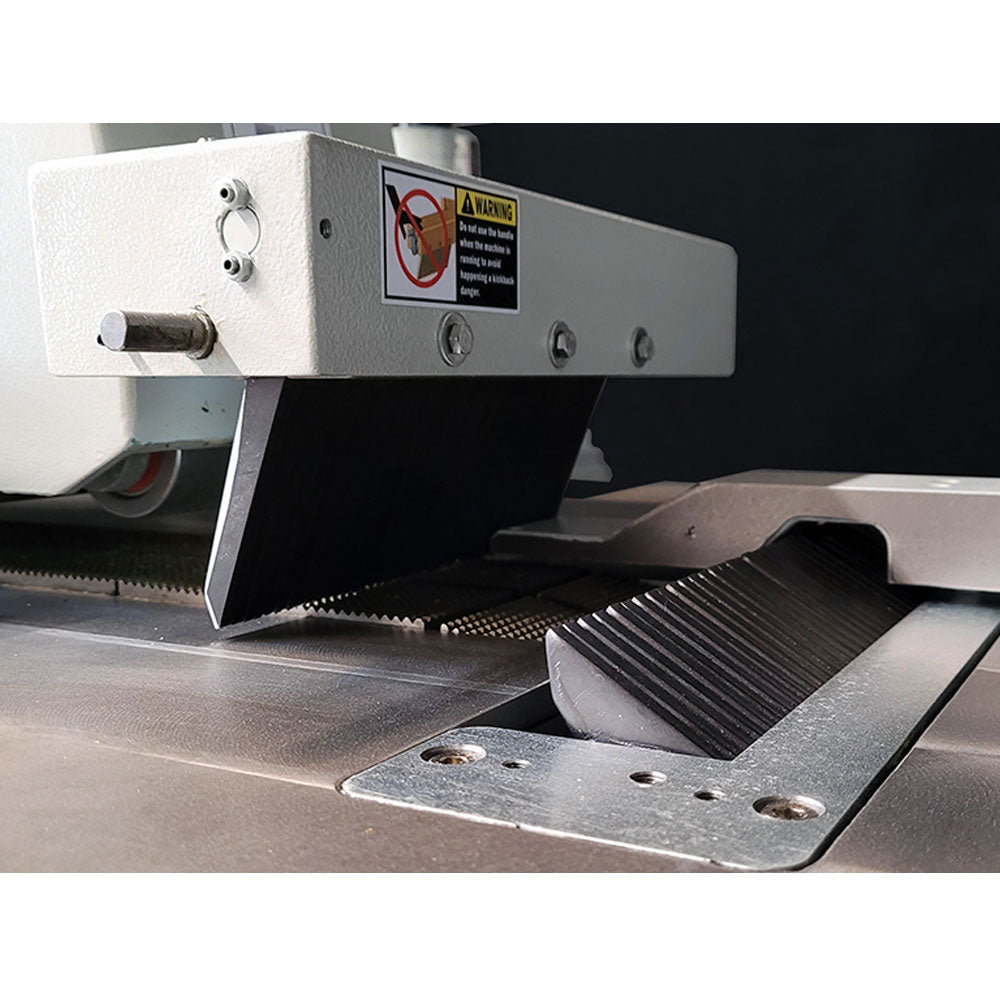

- 3 sets of anti-kickback fingers. 2 top and 1 set in the table for added operator safety

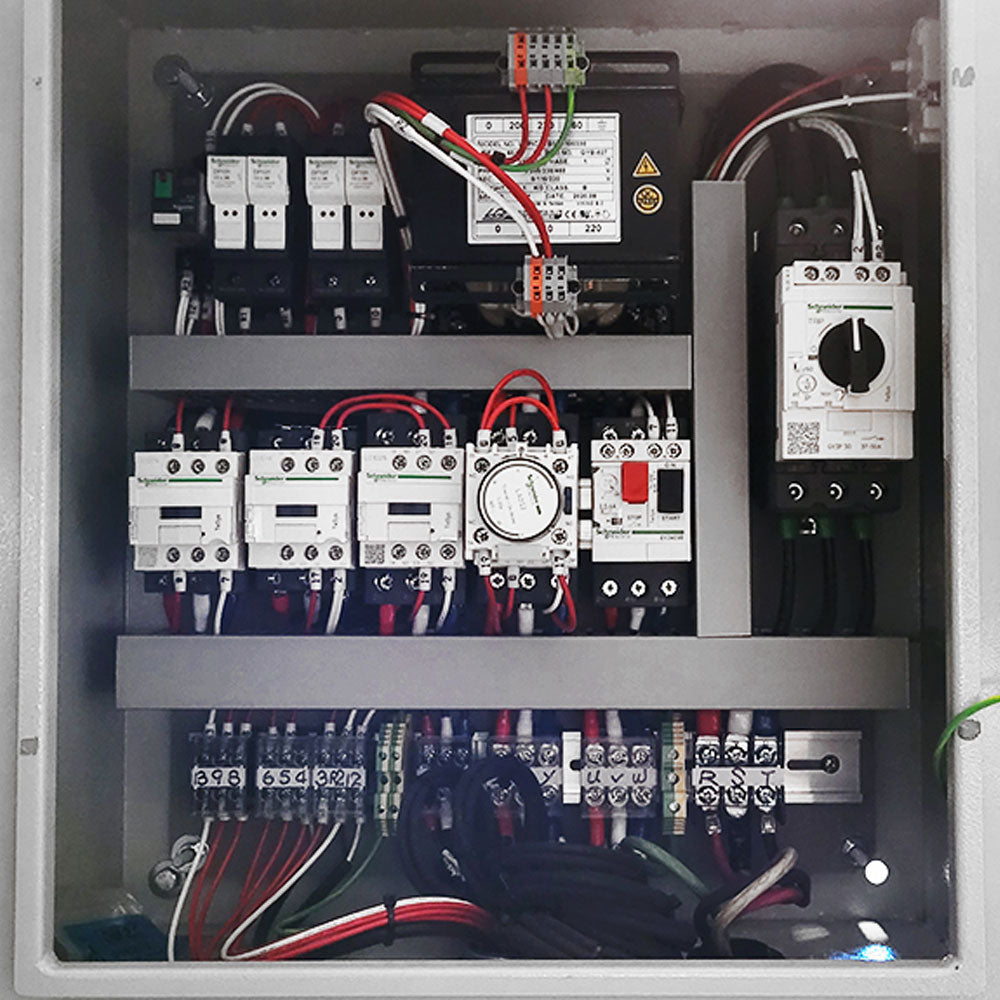

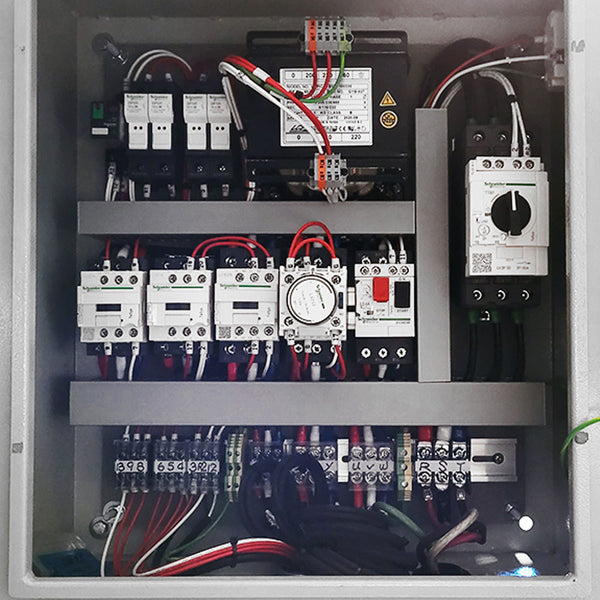

- Soft start – Star Delta starter reduces the amp draw on startup

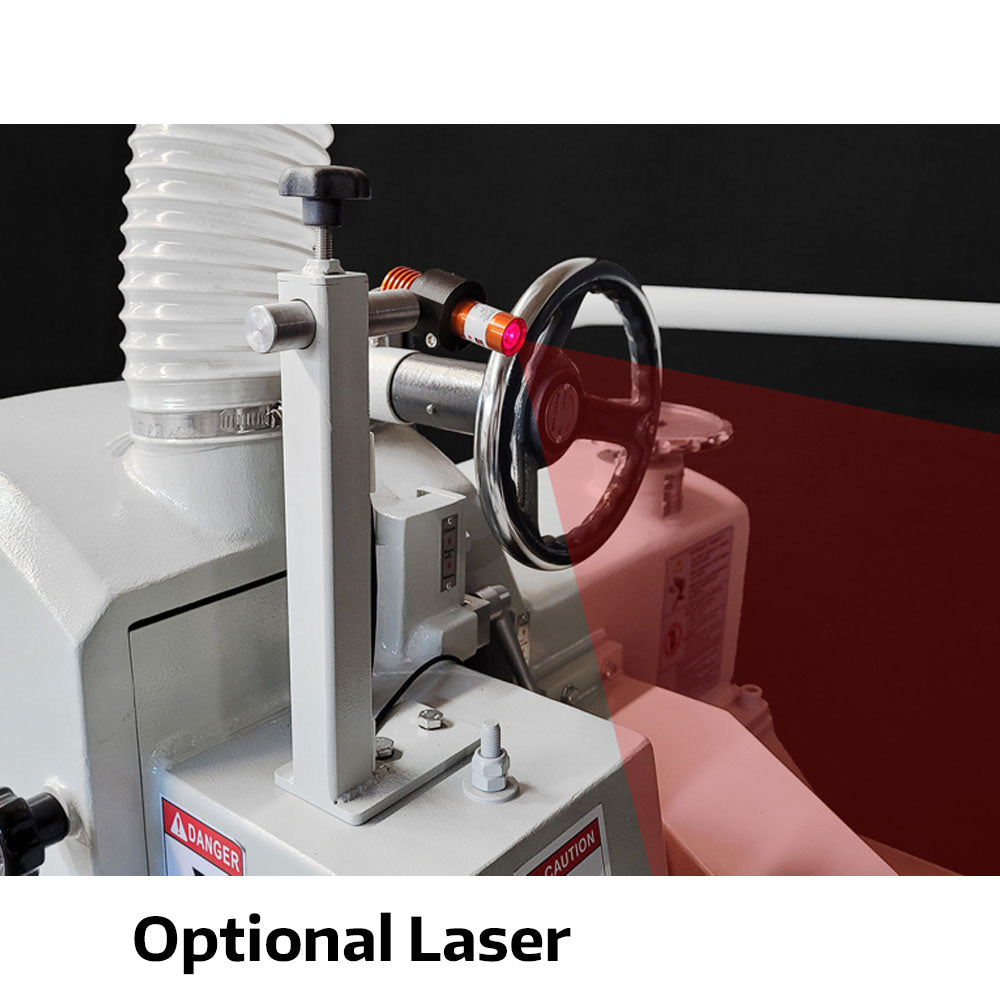

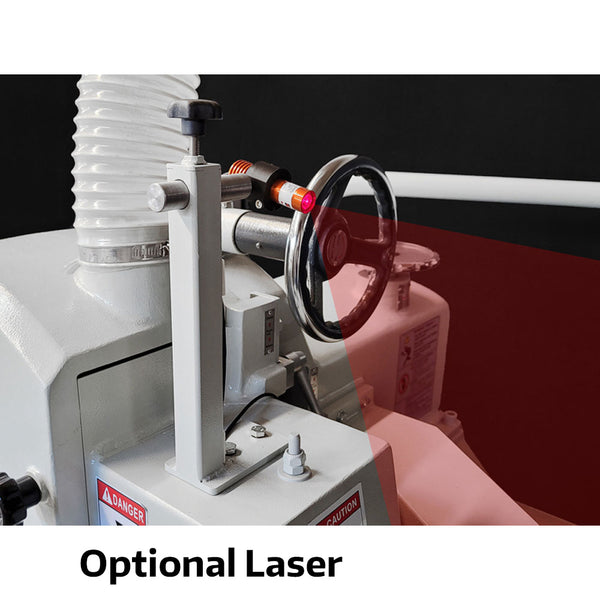

- Optional laser light to project the cutting line to achieve maximum material yield

Specs

Saw arbor diameter: 1″

Saw blade diameter: 10 – 12″

Saw arbor speed: 4,500 RPM

Feed Speeds – variable: 50 to 120 FPM

Maximum workpiece thickness: 3.34″ (12″ blade)

Minimum workpiece length: 8″

Glue line guarantee: 10’ (+/- 0.0098” or 0.25mm)

Distance between saw and column: 18″

Arbor motor: 15 HP

Feed motor: 1 HP

Electrical: 46 amps (230V); 23 amps (460V)

Table size: 39″ x 57″

Table height: 31-7/8″

Dust port size: 4″

Net weight: 2,090 lbs.

Machine dimensions: 68” x 46” x 62”

Shipping weight: 2,530 lbs.

Shipping dimensions: 65″ x 55″ x 60″

Video

*Shipping

Please note: Items being shipped to extremely remote areas or areas with limited delivery access (such as islands only accessible by ferry) may incur additional shipping or freight fees. If your order requires any additional fees other than what is already included in the price, you will be contacted before those fees are applied and before your item ships. This is rare and will not apply to most orders.