SCM Startech CN V CNC Boring and Grooving Center

- Price

- $ 49,575

Have questions or need help choosing a machine?

Call us at 260-637-0054 or email sales@oaktreesupply.com

Made in Italy. Ships from the United States.

- Freight Included In Price*

- Factory Install Included In Price

- In stock as of 1.8.26**

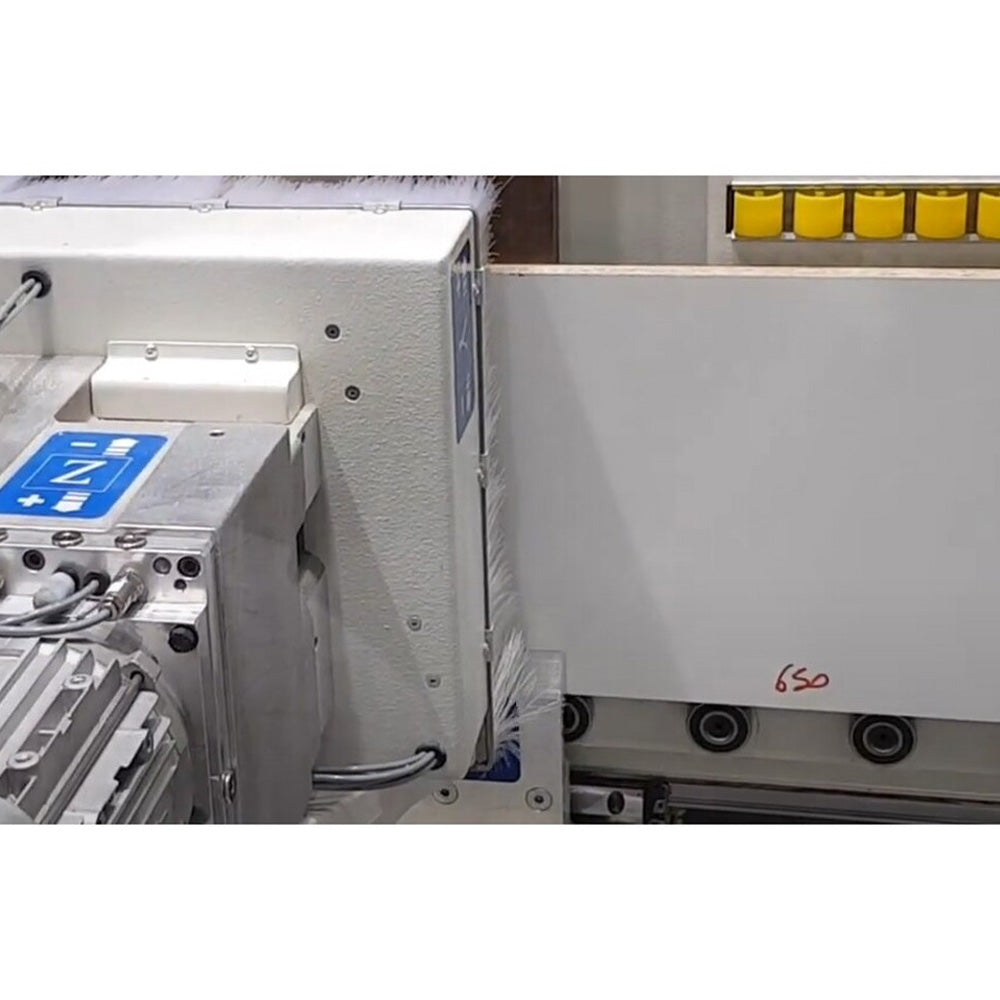

The Startech CN V is a versatile CNC drilling and grooving center designed to handle vertical surface drilling, horizontal drilling on all four sides, and precise X-axis grooving with integrated disc cutters. Its upright, welded-steel frame provides a stable base, while the phenolic worktable, complete with through-drilling grooves, offers a durable and supportive surface for a wide range of operations.

The electrical cabinet is neatly integrated into the base, keeping the machine’s footprint clean and compact. A NC-controlled clamp securely holds each panel and moves it into position under the operating head, while linear guides and recirculating ball screws ensure smooth, accurate motion across the X, Y, and Z axes. Direct-current motors drive the machine’s movements with reliability and precision. The NC control unit features a 10" color touchscreen with built-in self-diagnostics to simplify troubleshooting and operation.

The F11 Drilling Head includes:

- 8 vertical spindles

- 6 horizontal spindles

- Attachment for bits: 10 mm diameter

- Rotation speed: 4,460 rpm

- No. 1 integrated blade along X axis (125mm max. diameter)

- Blade rotation speed: 5,700 RPM

- 2.2 kW motor power

- Horizontal pneumatic drilling stroke along X-axis: 45 mm

Programming tools include automatic cycle optimization, flexible panel origin settings, USB program import, and compatibility with drilling programs generated from external CAD/CAM software.

Warranty

SCM warrants that every machine is free of defects in workmanship and materials for a period of one (1) year beginning on the date the machinery is accepted by the customer. Belts, bearings, and common electrical parts carry a six-month warranty. This warranty does not include wearable items or maintenance required in the ordinary course of operation.

Features

- Boring head with 8 vertical and 6 horizontal spindles

- Clamp controlled by the NC unit locks the panel and positions it under the operating head to be machined

- Prismatic linear guides with ball bearings

- Base, worktable, and gantry made of tubular welded steel

- Cooling fans for electric cabinet

- Sensor for panel calibration reads the X panel and automatically compensates errors on panel size programming

- Auto lubrication on moving parts

- Internal machine lighting

Specs

Air pressure: 6.5 bar

Compressed air pressure: 90 NI/min.

Min. required dust collection: 476 CFM

Exhaust air speed: 66 ft./sec. (20 m/sec.)

Exhaust outlet diameter: 4.75" (120 mm)

Electrical requirements*: 220V, 60Hz, 3-phase, 15 A

*Subject to change; must be verified prior to installation.

Axes

Max. panel dimensions X-Y-Z: 118.06" x 35.37" x 1.94" (3,000 x 900 x 50mm)

Min. panel dimensions X-Y-Z: 11.81" x 3.56" x 0.37" (300 x 90 x 10mm)

Max. axes speed X-Y: 66 fpm (20 m/min.)

Drilling head

Vertical spindles: 8 (5 on X Axis, 3 on Y)

Horizontal spindles: 6 (2+2X / 1+1Y)

Max. blade diameter: 4.87" (125mm)

Max. blade thickness: 0.19" (6mm)

Motor power: 3hp (2.2 kW)

Spindles rotation speed: 4,460 RPM

Blade rotation speed: 5,700 RPM

Optional Accessories

NOTE: The following accessories are optional and not included with the machine. They can be purchased at any time, but you can also take advantage of Accessory Bundle Pricing (applicable only at the time of machine purchase). Call us at (260) 637-0054 for more information and to place your order!

Maestro CNC programming software

Wireless barcode reader

-Includes electronic upgrade.

Keyboard type: Qwerty

-Includes wiring, support base, and keyboard.

*Shipping

Please note: Items being shipped to extremely remote areas or areas with limited delivery access (such as islands only accessible by ferry) may incur additional shipping or freight fees. If your order requires any additional fees other than what is already included in the price, you will be contacted before those fees are applied and before your item ships. This is rare and will not apply to most orders.

**Machinery Availability Key

Availability statuses found above the product description reflect where a machine is in the supply chain at the time of listing. Use the key below to help determine the lead time for this machine.

In stock for immediate shipment: The machine is in OakTree Supply's warehouse and is ready to ship.

In stock as of [date] / Low stock as of [date]: The machine is in the manufacturer’s U.S. warehouse and was available as of the last update we received. Estimated to ship in 3-5 business days. If low stock, please call us before ordering to confirm current availability.

Estimated to ship [date]: The machine is not yet in our warehouse or the manufacturer’s warehouse. The date shown is an estimate based on current production and shipping timelines and may change due to manufacturing schedules, import processing, or freight transit.

Dates listed as “estimated” are not guaranteed and may change. OakTree Supply is not responsible for delays in transit to or from our facility.