SCM Startech CN P CNC Universal Boring and Grooving Center

- Price

- $ 77,575

Have questions or need help choosing a machine?

Call us at 260-637-0054 or email sales@oaktreesupply.com

Made in Italy. Ships from the United States.

- Freight Included In Price*

- Factory Install Included In Price

- Estimated to ship June 2026**

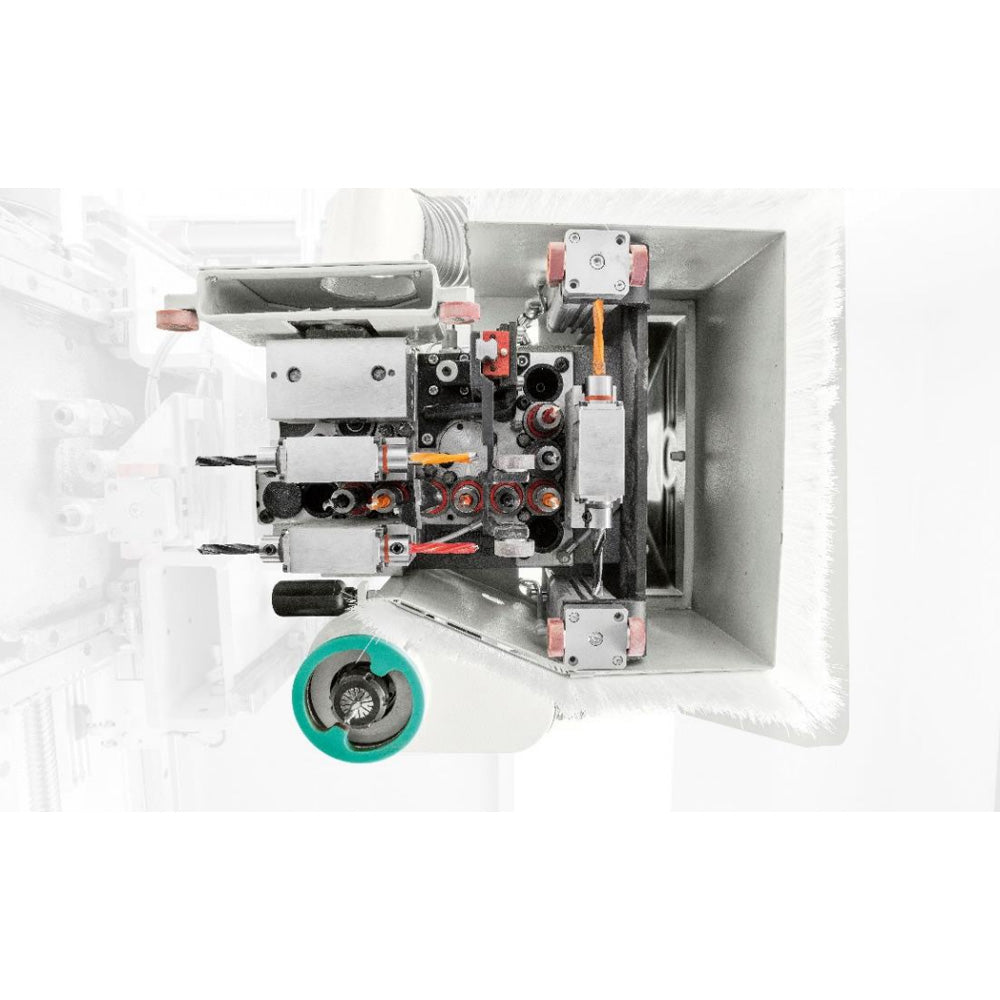

CNC drilling and grooving center with fixed worktable and mobile workpiece. This machine is capable of vertical drilling on the panel surface, horizontal drilling on all 4 sides, grooving with integrated disc cutter along “X” axis, and standard vertical routing.

A structure made of welded steel plates creates a large support surface on which the work tables are fixed. The electrical cabinet is integrated in the base. The work table is made of phenolic material with grooves to allow the through boring.

An intelligent clamp directly controlled from the NC locks the panel to be processed and positions it in sequence under the operating head to execute the requested machining. It slides along "X", "Y" and "Z" axes of prismatic linear guides and preloaded recirculating ball bearings. Group positioning and machine motion is carried out by means of digital brushless motors.

The SCM "Maestro CNC" software allows users to create projects and geometrical drawings to be automatically converted in drilling-routing programs for the machine. It also contains a database that allows customer to save machinings. Once the machining has been saved, it can be applied any time on different geometries.

The low friction work table is made of Bakelite, a hard, infusible, and chemically resistant plastic. It features an automatic central side-alignment device with pneumatic positioning. The lubrication nozzles of the moving parts are grouped in a single position, allowing the operator the simple manual daily maintenance in very reduced time.

The Startech CN P contains the following hardware devices and software programs:

PC-Office

- Windows 10 operating system

- 19" LCD color display

- Qwerty keyboard

- Hicam interface machine software

Telesolve

Teleservice system to connect the machine pc with the service center via Internet. Software equipment: connecting program which allows:

- Operator's interface visualization

- Signals diagnosis

- On-line verification and modification of the status of configurations, parameters and machine programs

- Data back-up and files transfer operations

- Upgrade operations for machine logics and operator's interface

- Network cable and connection is not provided by SCM

CAD/CAM programs import

Machine can import drilling programs carried out with external softwares.

Hardware key with "Maestro cnc" programming software.

Features

- Horizontal drilling in X, up to 11 mm minimum quota in Y

- Grooving up to 120 mm minimum quota in "Y" to the max. pass depth; from 60 mm to 120 mm: 4 mm max. depth

- 30 mm maximum vertical drilling depth

- 30 mm maximum horizontal drilling quota with respect to the panel surface (face 1)

- Through drilling on panels with thickness up to 22 mm with 8 mm bits and 20 mm with 10 mm bits

- Integrated blade unit with:

- Rotating speed: 5,500 RPM

- Tool attachment: 20 mm bore

- Blade = 125 mm maximum diameter; 6mm maximum thickness

Specs

Axes

Max. panel length: 3,050 mm

Min. panel length: 200 mm

Max. panel width: 900 mm

Min. panel width: 80 mm

Max. panel thickness: 60 mm

Min. panel thickness: 10 mm

Max. X axis speed: 40 m/min.

Max. Y axis speed: 40 m/min.

Drilling head

Vertical spindles: 8 (5X-3Y)

Horizontal spindles: 6 (2+2X-2Y)

Rotating spindles motor power: 3hp

Spindle speed: 4,200 RPM

Fixed integrated disc cutter (direction): X

Max. diameter of disc cutter: 125 mm

Disc cutter rotating speed: 5,500 RPM

Electrospindle

Motor power: 7.5hp

Min./Max. speed: 1,000 / 18,000 RPM

Tool changer: Manual

Max tool diameter: 20 mm

Installation

Compressed air consumption: 50 NI/min.

Extraction air consumption: 1900+540+1200 (+540 vers.R) m³/h

Exhaust air speed: 30 m/sec.

Installed motor power: 15.2 (20.7 vers. R) kVA

Exhaust outlet diameter: 150+120+80 (+80 vers R) mm

Video

*Shipping

Please note: Items being shipped to extremely remote areas or areas with limited delivery access (such as islands only accessible by ferry) may incur additional shipping or freight fees. If your order requires any additional fees other than what is already included in the price, you will be contacted before those fees are applied and before your item ships. This is rare and will not apply to most orders.

**Machinery Availability Key

Availability statuses found above the product description reflect where a machine is in the supply chain at the time of listing. Use the key below to help determine the lead time for this machine.

In stock for immediate shipment: The machine is in OakTree Supply's warehouse and is ready to ship.

In stock as of [date] / Low stock as of [date]: The machine is in the manufacturer’s U.S. warehouse and was available as of the last update we received. Estimated to ship in 3-5 business days. If low stock, please call us before ordering to confirm current availability.

Estimated to ship [date]: The machine is not yet in our warehouse or the manufacturer’s warehouse. The date shown is an estimate based on current production and shipping timelines and may change due to manufacturing schedules, import processing, or freight transit.

Dates listed as “estimated” are not guaranteed and may change. OakTree Supply is not responsible for delays in transit to or from our facility.