SCM Startech 27 Multi-Boring Machine

- Price

- $ 11,375

Have questions or need help choosing a machine?

Call us at 260-637-0054 or email sales@oaktreesupply.com

Made in Italy. Ships from the United States.

- Freight included in price*

-

Estimated to ship May 2026**

- Machine configuration

The Startech 27 is a heavy-duty, single-head multi-boring machine that is capable of performing horizontal, vertical, and 45° boring operations for wood and similar materials.

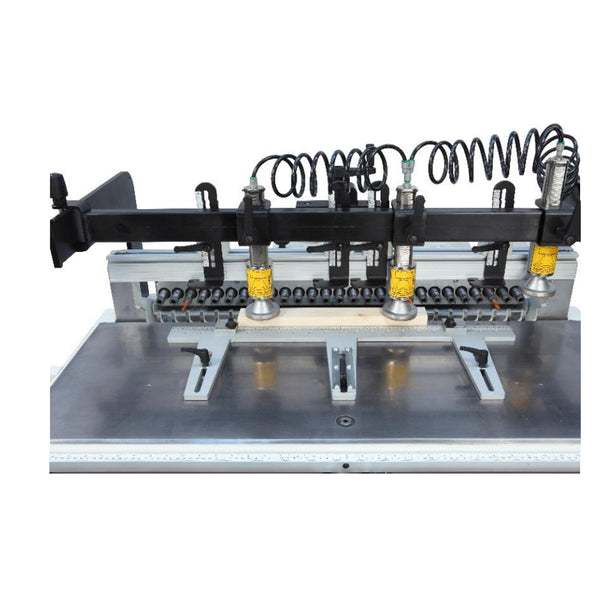

The base and worktable are made of both bent and welded steel plates to create a large workpiece support surface for large jobs. Right/left extensions with retractable stops L=3000mm are now standard! The extensions can be installed on the guides already mounted on the machine and are positioned at 90° with reference to the boring line; They are complete with 4 retractable stops (which may also be used as rear guides) and two upper pressure cylinders for the workpieces hold-down. The compass device allows the quick positioning of the guide located opposite the one in use without the necessity of metric reads.

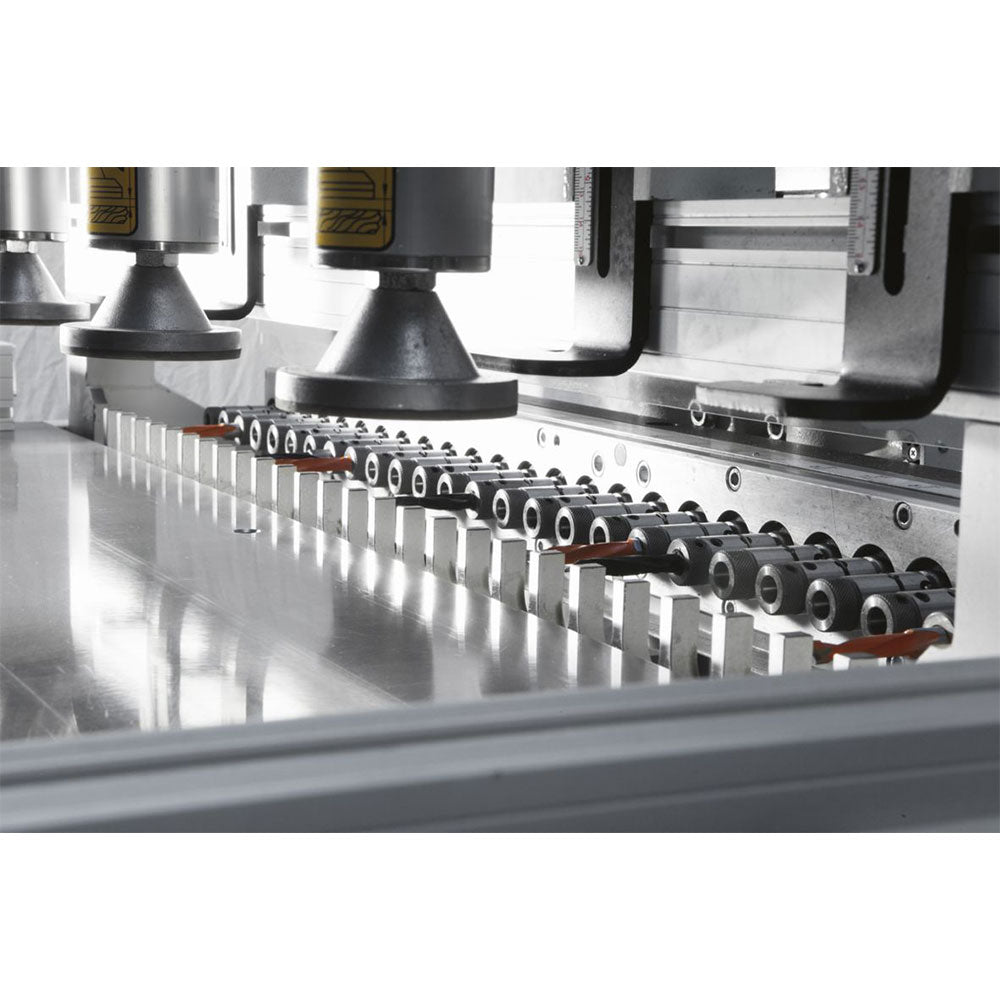

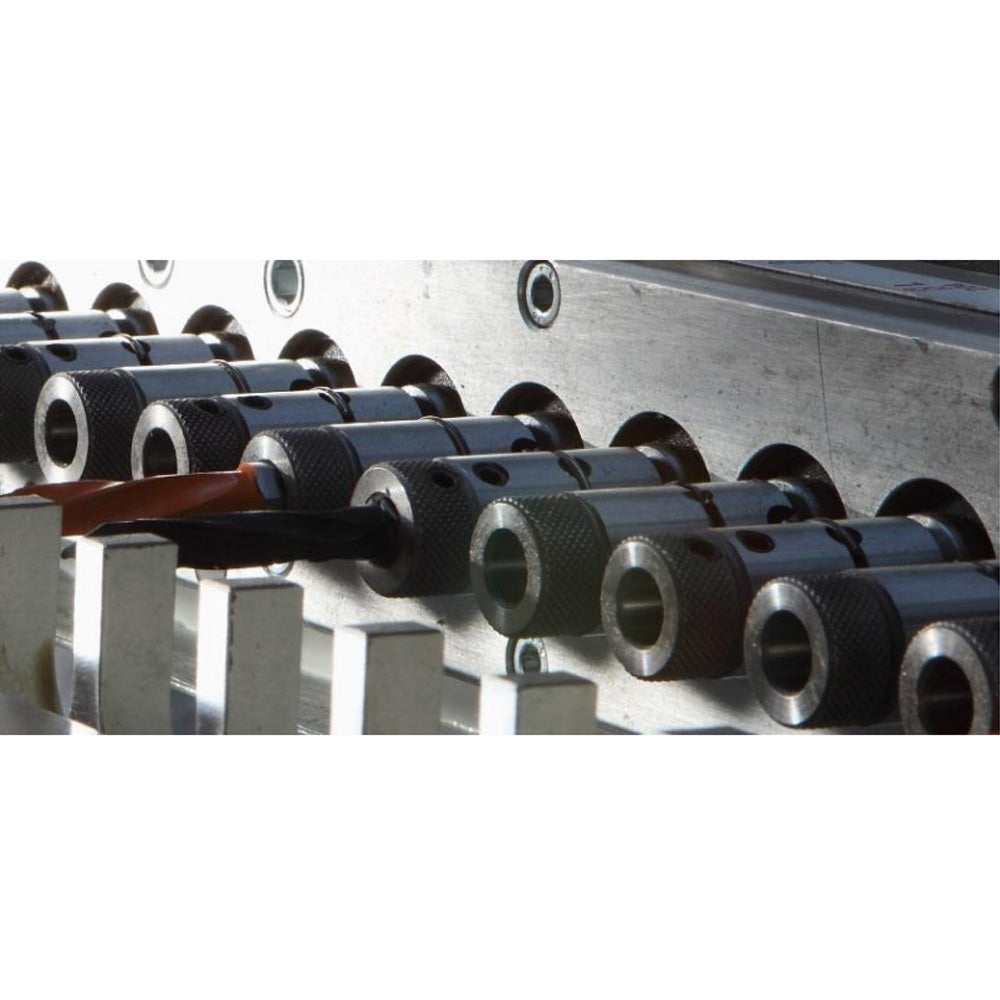

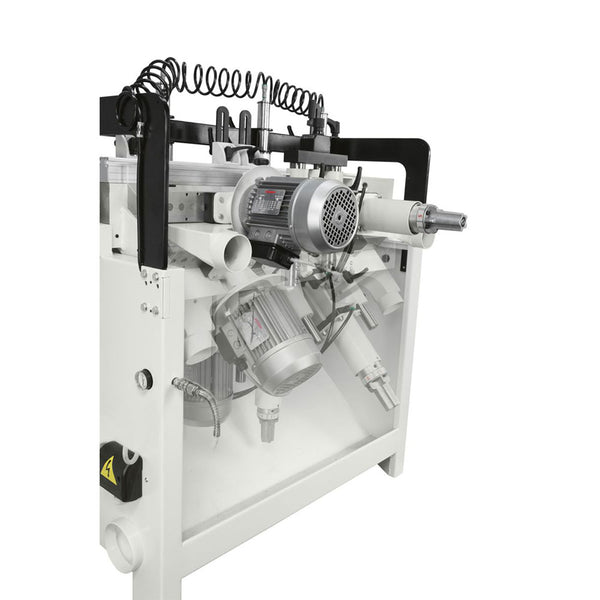

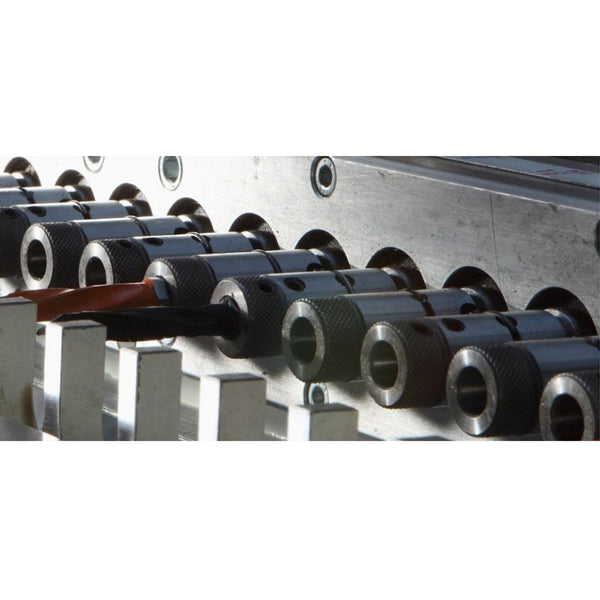

The standard operating unit features a boring head with quick attachment spindles (32 mm center-to-center) with an aluminum structure and gears. The boring head movement is created through a pneumatic piston. The boring unit can be automatically positioned horizontally or vertically. Boring head rotation can be adjusted from the control board. All spindles are preset for quick-change adaptors.

The gantry uses an ultra-thick steel structure, with depth adjustment, to easily support the load-bearing stress. Pneumatic cylinders for the workpieces lock when machining pieces. Automatic head movement for the horizontal and vertical boring unit positioning, with locking at 45° rear stops, lateral stops, and extensions for long workpieces, is engineered to ensure the best working precision on the piece.

Features

- Line and construction boring with 45° positive stop

- Two pneumatic clamps

- Preset with a total of 18 quick-change 10mm adaptors

- Right-left extension fence with retractable stops (3000mm)

- Fence for horizontal boring at 45°

- One supplementary top-pressure cylinder

- Device for working narrow workpieces

- Calibration jig

Specs

Head Group

Number of spindles: 27

Center-to-center distance between spindles: 32 mm

Total number of 10 mm quick change adapters: 18

Spindles speed: 3,000 RPM

Motor power of spindles: 2 Hp (1.5kW)

Number of revolving turret positions: 6

Max. stroke of boring unit: 63 mm

Stroke of hydraulic brake: 50 mm

Tool

Max. tool length: 80 mm

Max. tool diameter: 40mm

Panel

Max. horizontal boring height: 50 mm

Max. width under the “gantry structure”: 1.025 mm

Max. distance of vertical borings from panel edge: 110 / 320mm

Min. panel thickness: 10 mm

Max. panel thickness: 60 mm

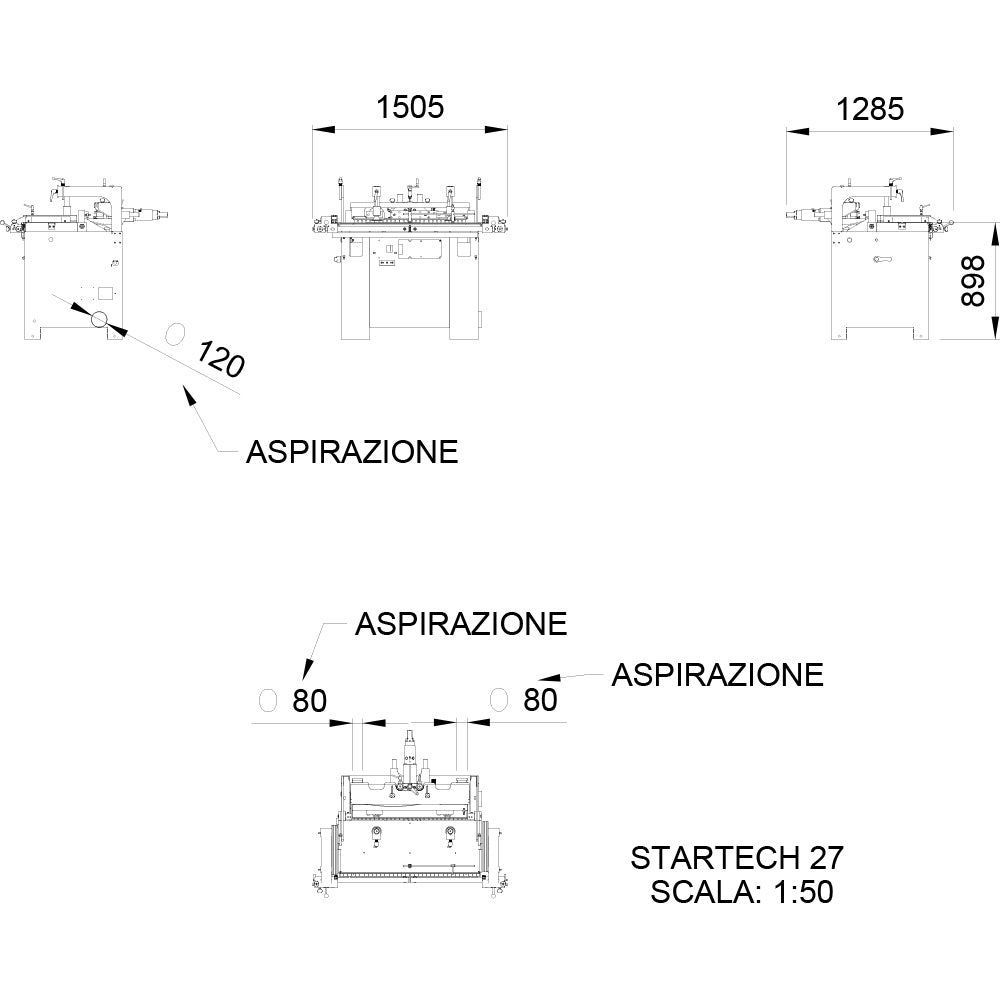

Installation

Compressed air pressure: 6 bar

Compressed air consumption: 3.6 Nl/cycle

Exhaust outlets diameter: 120+60+60 mm

Exhaust air speed: 30 mm

Exhaust air consumption: 1220+300+300 m3/hr

Working table dimension: 1,096 x 407 mm

Worktable height from floor: 900 mm / 35.5”

Weight: 815 lbs. / 370 kg

Electrical requirements: 230V, 3-phase

Video

*Shipping

Please note: Items being shipped to extremely remote areas or areas with limited delivery access (such as islands only accessible by ferry) may incur additional shipping or freight fees. If your order requires any additional fees other than what is already included in the price, you will be contacted before those fees are applied and before your item ships. This is rare and will not apply to most orders.

**Machinery Availability Key

Availability statuses found above the product description reflect where a machine is in the supply chain at the time of listing. Use the key below to help determine the lead time for this machine.

In stock for immediate shipment: The machine is in OakTree Supply's warehouse and is ready to ship.

In stock as of [date] / Low stock as of [date]: The machine is in the manufacturer’s U.S. warehouse and was available as of the last update we received. Estimated to ship in 3-5 business days. If low stock, please call us before ordering to confirm current availability.

Estimated to ship [date]: The machine is not yet in our warehouse or the manufacturer’s warehouse. The date shown is an estimate based on current production and shipping timelines and may change due to manufacturing schedules, import processing, or freight transit.

Dates listed as “estimated” are not guaranteed and may change. OakTree Supply is not responsible for delays in transit to or from our facility.