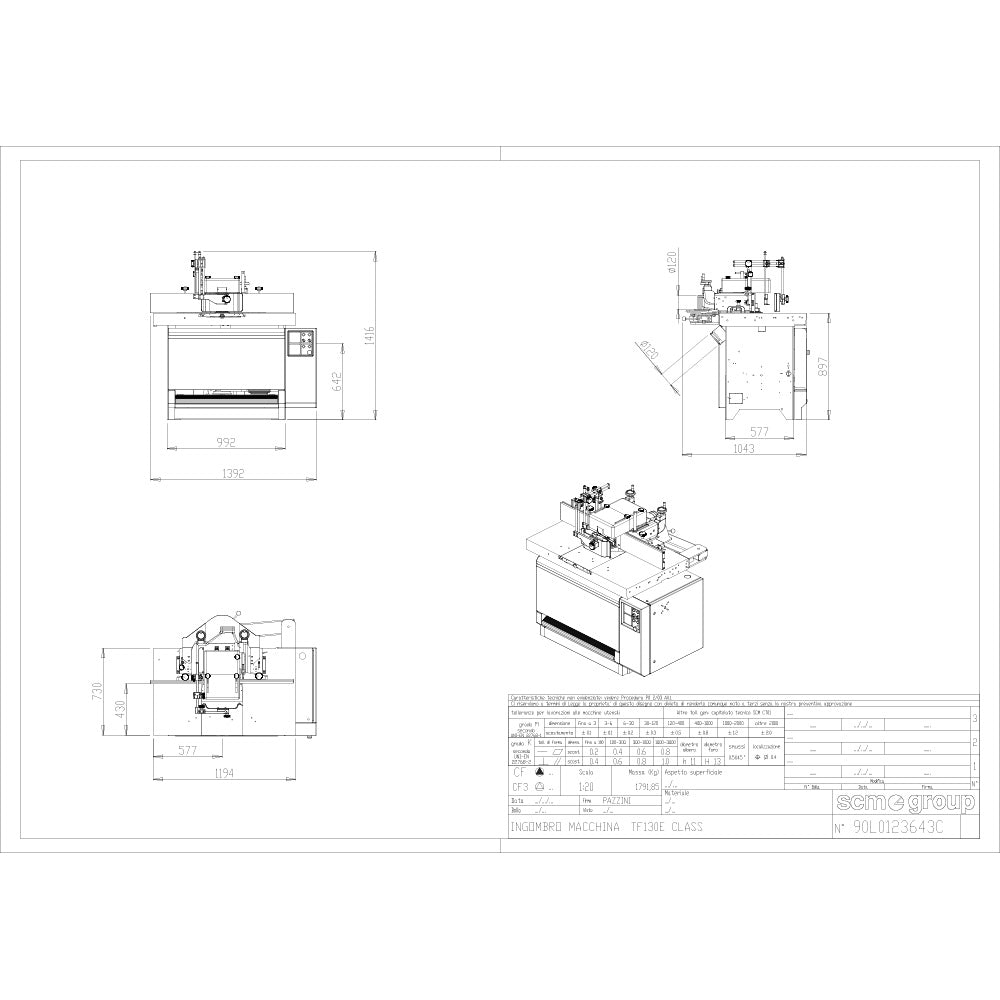

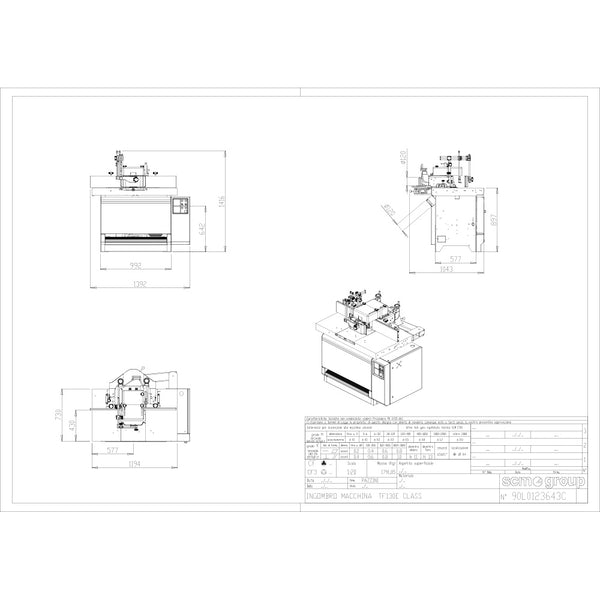

SCM Class TF 130E Fixed Spindle Shaper

- Price

- $ 26,475

Have questions or need help choosing a machine?

Call us at 260-637-0054 or email sales@oaktreesupply.com

Made in Italy. Ships from the United States.

- Freight Included In Price*

- Factory Install Included In Price

- Low stock as of 1.2.26**

A must for the serious woodworker, the Class TF 130E is the SCM shaper that combines quality and value for your investment. It has a very robust structure and all the controls can be accessed on the front of the machine for easy use. The TF 130E features powered lifting with digital readouts.

Monoblock technology is used in the design and fabrication of this base. The solid, welded base undergoes a treatment called normalization which stabilizes the metal and assures exact tolerances. All machine mechanisms are mounted, aligned, and referenced to the base. This design is vastly superior to frames that are bolted together and have no true reference point.

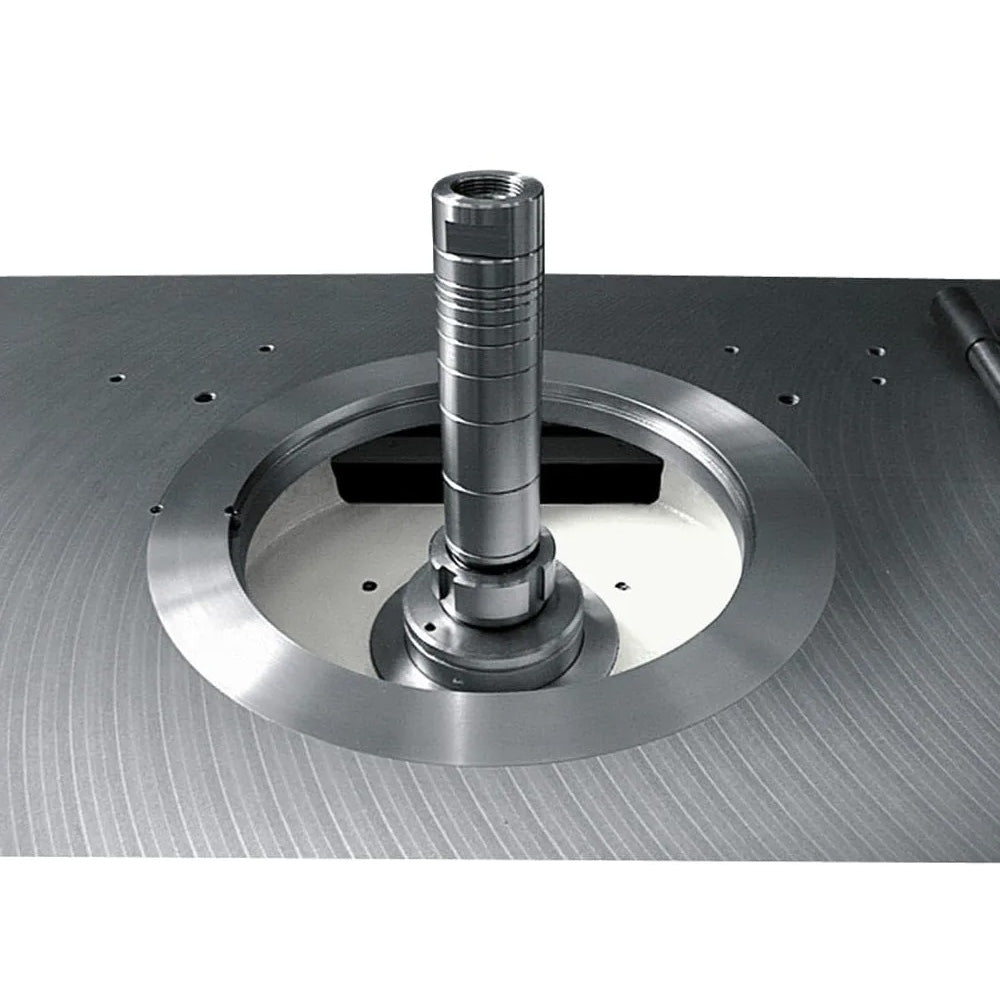

One thing that can degrade the quality of finish from a shaper is the vibration transmitted from the spindle to the cutter. Minimizing vibration is even more critical when cutting tall profiles or using stacked tooling. SCM ensures maximum quality in its shapers by using very large spindle assemblies whereby the increased mass of the spindle absorbs vibrations and eliminates whipping action at the top of the spindle.

A standard feature on the Class TF 130E is the MK 5 interchangeable tapered spindle. This feature allows the use of different spindles for various tooling with different spindle diameters. An upgrade to a larger shaper does not mean that all tooling needs to be replaced. Special tools can continue to be used simply by changing out to a different spindle. A 1-1/4” spindle comes standard.

The Class TF 130 comes standard with a large shaper hood with memory pins. If removed, the hood will go right back into the same position, so it is accurate and repeatable. The fences are adjusted by means of a mechanical hand crank that features a digital (mechanical) readout of the fence positioning. This convenient feature makes it simple to set up the hood for a number of different profiles and operations.

Features

- Powered tool-holder shaft lifting, complete with electronic digital readout of working height

- Spindle moulder fence with mechanical adjustment

- Spindle moulder fence with continuous linear adjustment by handwheels accessible from machine front:

- *adjustment of entire fence in respect of tool diam.

- *adjustment of entry fence for thick removal

- Mechanical readout for the adjustment

- Wooden tables and connecting bars

- 250 mm max. tool diameter

- "FAST" section table replacing the table rings to optimize the working support under the cutting tool, with

- manual external adjustment

- 3,000 / 4,500 / 6,000 / 7,000 / 10000 RPM spindle speeds

- Electric speed display dial (CE and electrical protections versions)

- Electrical presetting for feeder (CE version)

- Reverse spindle rotation with electrical interlocking for reverse operation

Specs

Motor power: 11hp (8 kW)

Work table dimensions: 47.19" x 28.69" (1,200 x 730mm)

Working length of spindle: 7" (180mm)

Spindle base projection: 3.56" (92mm)

Max. tool dia. retractable (under table): 11.75" x 3.31" (300 x 85mm)

Dust port dia.: 4.69" (120mm)

*Electrical requirements: 220V, 3-phase, 25 A

*Subject to change; must be verified prior to installation.

*Shipping

Please note: Items being shipped to extremely remote areas or areas with limited delivery access (such as islands only accessible by ferry) may incur additional shipping or freight fees. If your order requires any additional fees other than what is already included in the price, you will be contacted before those fees are applied and before your item ships. This is rare and will not apply to most orders.

**Machinery Availability Key

Availability statuses found above the product description reflect where a machine is in the supply chain at the time of listing. Use the key below to help determine the lead time for this machine.

In stock for immediate shipment: The machine is in OakTree Supply's warehouse and is ready to ship.

In stock as of [date] / Low stock as of [date]: The machine is in the manufacturer’s U.S. warehouse and was available as of the last update we received. Estimated to ship in 3-5 business days. If low stock, please call us before ordering to confirm current availability.

Estimated to ship [date]: The machine is not yet in our warehouse or the manufacturer’s warehouse. The date shown is an estimate based on current production and shipping timelines and may change due to manufacturing schedules, import processing, or freight transit.

Dates listed as “estimated” are not guaranteed and may change. OakTree Supply is not responsible for delays in transit to or from our facility.