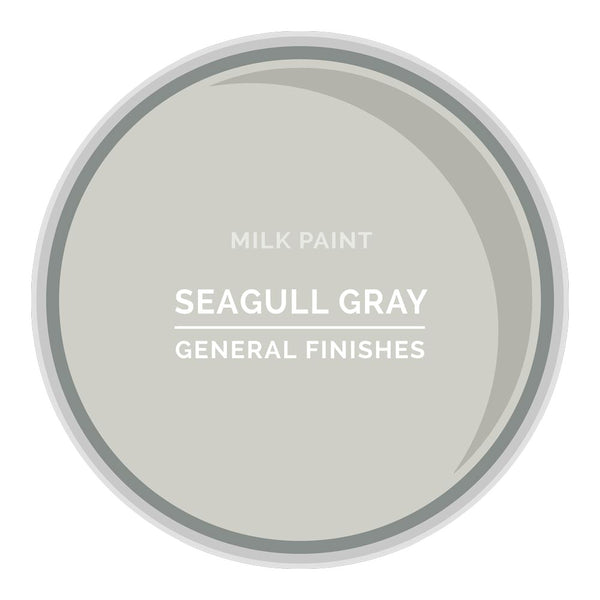

General Finishes Milk Paints - Quart

- Price

- $ 46

Have questions? Give us a call at 260-637-0054.

General Finishes Milk Paints are premium acrylic, water-based paints named for their low-luster sheen which mimics the look of old-world furniture paint. Not a true "casein based milk paint" but a modern version of old world paint with a strong mineral base. It is adaptable and UV resistant and may be applied by brushing or spraying and possesses excellent flow and leveling properties. Milk paints are formulated with zero-VOC colorants and pre-mixed for your convenience. They can be used on interior or exterior projects without a topcoat, including raw wood, pre-finished wood, and fiberglass.

You can mix it, lighten it, distress it, glaze it, layer different colors or antique it - perfect for upcycling or repurposing furniture.

Also available in pints.

Don't forget your brushes and sandpaper!

Warning: Do not use water-based products with Linseed Oils or Danish Oils.

Note: Colors shown are for reference only. Your results may vary based on species, grain, sanding, etc.

Specs

Base Type: Water

Sheen: Flat low luster (10-15)

Interior or Exterior: Interior/Exterior

Type: Acrylic Paint

Coats: 1+ coats

Application Method: Brush, Roll, Spray, Pad

Usable over existing finishes: Yes

Spray Tip Sizes: HVLP 1.8mm-2.0mm

Topcoat Required: Self-Sealing

Dry Time - Touch: 30+ min.

Dry Time - Recoat: 2+ hrs.

Dry Time - Light Use: 7-10 days

Dry Time - Cure: 21 days

Coverage: 100-125 sq. ft.

Viscosity: Thick

Viscosity (cPs): 2,000-3,000

Durability (Highest, High, Medium, Low): High

Preparation

Raw wood

- Sanding schedule: 120-grit sandpaper followed by 150-grit. Do not over-sand with fine-grit sandpapers; this will close and seal the wood grain, preventing ideal color absorption. Do not use steel wool with water-based finishes; the particles will get trapped in the finish and rust.

- Remove dust with a vacuum, compressed air, an oil-free tack cloth or a water-dampened rag.

- Let dry completely before applying General Finishes product.

Sealed surface

- Scuff clean with a Scotch Brite pad or maroon synthetic steel wool and a 50:50 mix of denatured alcohol and water. Dry 1-2 hours. Avoid cleaning with products containing phosphates (salt), which can linger in the substrate and produce a white haze. If your project requires a deeper cleaning, see Power Prep Cleaning Highly Used Existing Finishes below.

- Sand lightly with a fine-grade (220-320) foam sanding sponge or 400-grit sandpaper.

- Remove dust with a vacuum, compressed air, an oil-free tack cloth or a water-dampened rag.

- Let dry completely before applying General Finishes product.

Directions

- Work in a well-ventilated area.

- Stir paint to reincorporate solids that have settled to the bottom of the can before and throughout the application process.

- Thin as desired with distilled water; start with 5%, adding up to 10% by volume. Do not use flowing agents such as Floetrol. This paint already contains a flow agent and outside products may not be compatible.

- Increase open time, if needed, with up to 10-15% General Finishes Extender if allowed by local regulations. GF Extender will improve flow and leveling and increase open time, which is helpful in dry climates. California Residents: Adding more than 2% of GF Extender will make the products non-compliant per SCAQMD Regulations.

- Apply as many coats as needed for desired coverage. 2-3 coats are standard but additional coats may be required when using colors with less "hide properties," such as bright reds, greens, yellows and whites.

-

Hand application: Using a synthetic bristle brush, foam brush, pad applicator, or microfiber roller such as Whizz or AllPro brand, apply using smooth, even strokes.

Spray application: Before spraying, strain paint through a medium-mesh filter. Spray wet films at 3-5-mil thickness. HVLP: 1.8 mm-2 mm spray tip, medium air cap. Verify tip sizes with your equipment supplier. Keep your gun at a 90° angle, 6-8" from the surface. On large, flat areas, use wet, even patterns 6-8" wide. For narrow surfaces, reduce the fan pattern to 2-3" wide to reduce overspray. Overlap each pass 25% to conceal lines. Wear full filter NIOSH/MSHA-approved respiratory & eye protection.

Face frames on cabinets: Milk Paint can be applied successfully to cabinet face frames, edges or drawer fronts with a brush, pad or small cabinet-specific roller such as Whizz or AllPro brand. - Dry 2+ hours between coats and before General Finishes water-based topcoat in ideal conditions: 70°F/20°C; 50-70% humidity. Be sure to allow adequate dry time. You can tell if a water-based finish is dry if it forms a powder when lightly sanded with a fine-grade (220-320) foam sanding pad. If in doubt, wait longer. Rushing dry time can cause clouding/blush in topcoat due to moisture trapped between coats.

- Increase dry time if humidity is over 80%, 3+ coats are applied, thick coats are applied, applying over an existing sealed finish, applying over products from other brands, or layering General Finishes water- and oil-based products.

- Water over oil: Let oil-based products dry 72+hrs before applying water-based products

- Oil over water: Let water-based products dry 24+hrs before applying oil-based products

- To accelerate dry time in humid conditions, add General Finishes Accelerator and work in a space with good ventilation and air movement. If you decide to re-coat before the recommended time, test dryness.

- Finish sand between coats with a fine-grade (220-320) foam sanding sponge or 400-grit sandpaper to improve smoothness and adhesion. Do not use conventional steel wool.

- Remove dust with a vacuum, compressed air, an oil-free tack cloth or a water-dampened rag.

Video

I've been using GF paint for a few years and am always pleased with how smoothly it brushes on, its coverage and durability. For my latest project, I was looking for a furniture paint to refinish an outdoor table and was pleased to learn that GF paint can be used for indoor and outdoor furniture. I used the colors persimmon and basil. As far as shipping, my order arrived quickly and was packaged so well that the can arrived in perfect condition.

I was in need of a discontinued quart of paint and Oak Tree Supply came through. Within a week I received my order along with a complimentary note pad and pen. Great service. I will definately use them again.

Love everything from the colors, to the ease and the milk paint finish of General Finishes. As a business owner, I’ve tried other brands to paint furniture over the last 15 years and GF is the best by far.

As a professional painter for more than 20 years, now retired and remodeling my own home, this is the best paint I have ever used. Customer service at Oak Tree Supply is also the best!