Cantek C372 36" Two Head Wide Belt Sander (60" Belt)

- Price

- $ 32,025

Have questions or need help choosing a machine?

Call us at 260-637-0054 or email sales@oaktreesupply.com

Made in Taiwan. Ships from the United States.

Our Easy Purchase Guarantee:

- In stock as of 2.25.26

- Freight included in price.*

The Cantek C372 37″ Two Head Widebelt Sander is perfect for any small to mid-sized shops looking to achieve outstanding results. Its robust construction is the best in its class and provides superior sanding results. The flexibility with quick change abrasive belts, allows for more applications in a shorter time frame, helping to assist and meet deadlines.

The C372 has a relatively small footprint providing greater access for smaller shops to accomplish bigger results. Equipped with motorized thickness adjustment with digital input control with settings to 0.001” / 0.01mm for precise table setting without compromise!

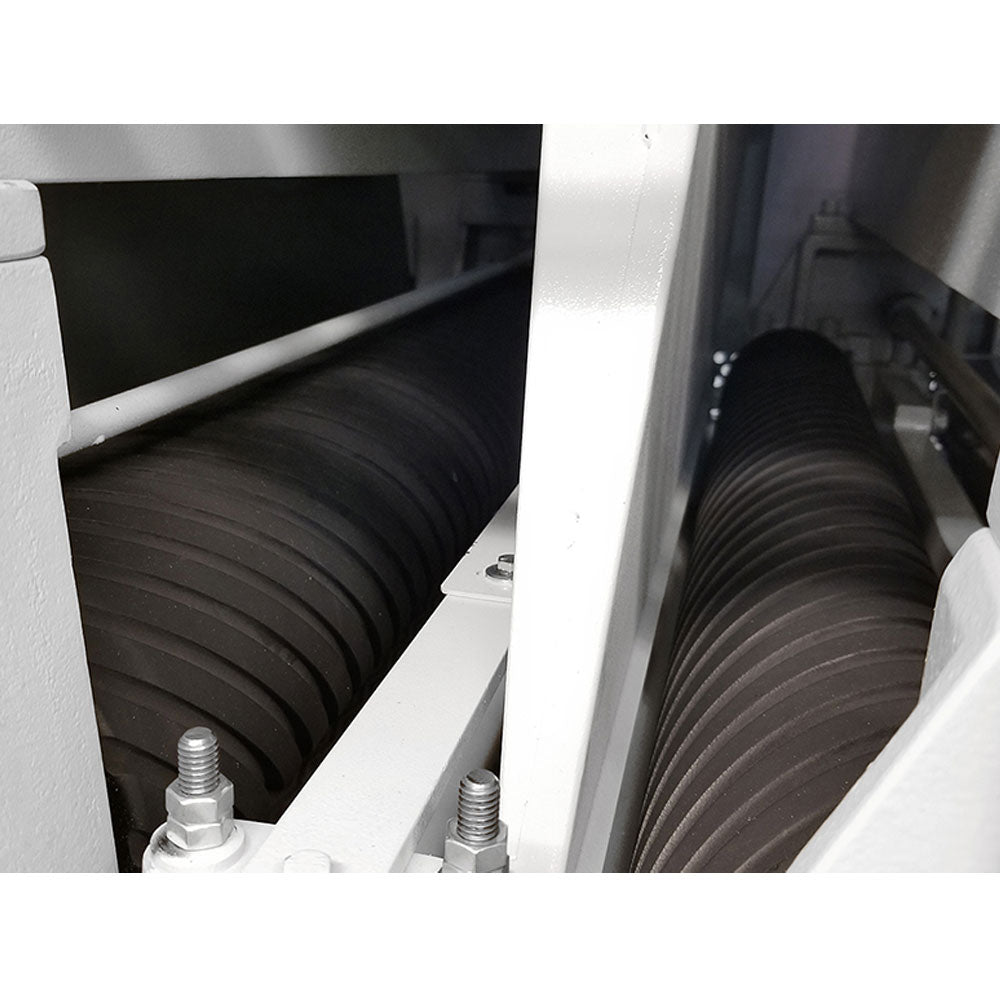

Equipped with 2 sanding heads: Contact Drum for calibration sanding, and Combination head with adjustable platen for both calibration & finish sanding. A quick-release handle & pneumatic belt tensioning to allow for fast belt changeover. Both sanding head frames are made from industrial cast iron.

Centrally located control panel for convenient operator access. Includes digital motorized thickness adjustment to 3-decimal places in Inch & 2-decimals in MM. It is also equipped with an emergency stop button, individual ammeters for load monitoring, and an hour meter to aid in maintenance.

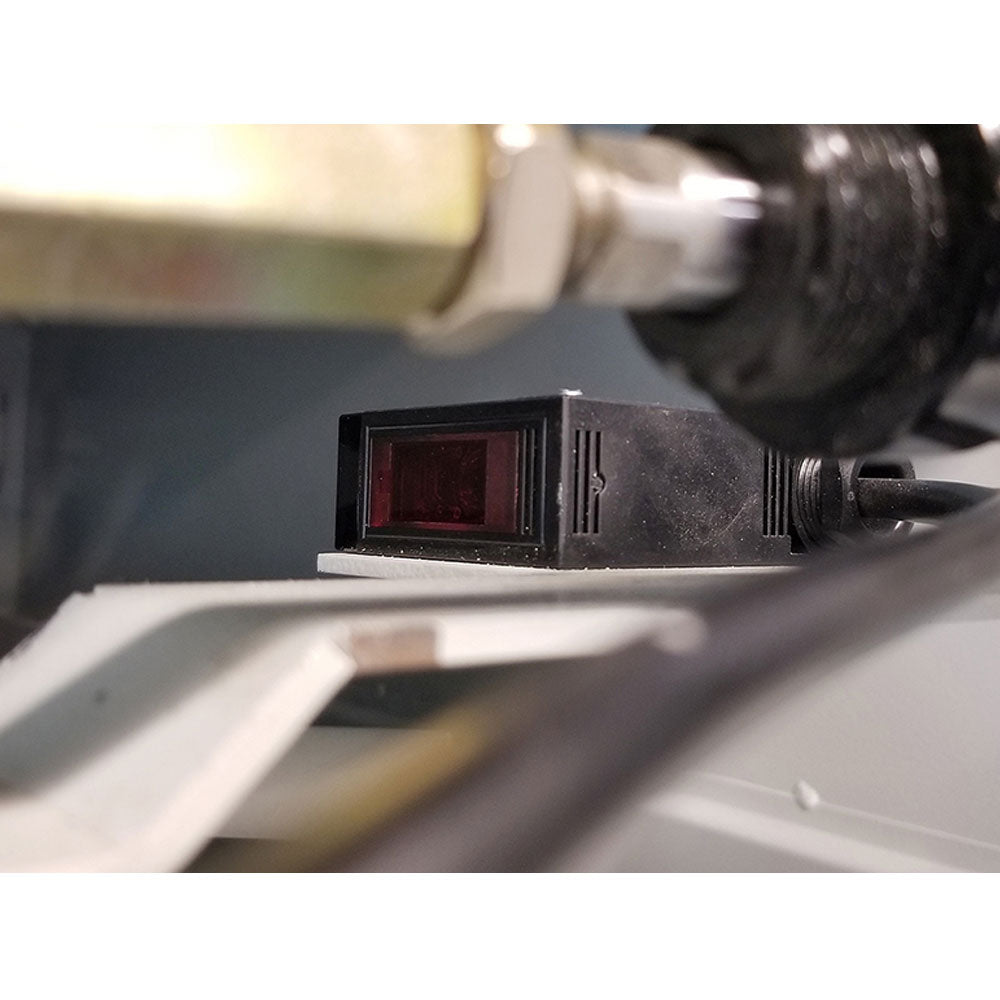

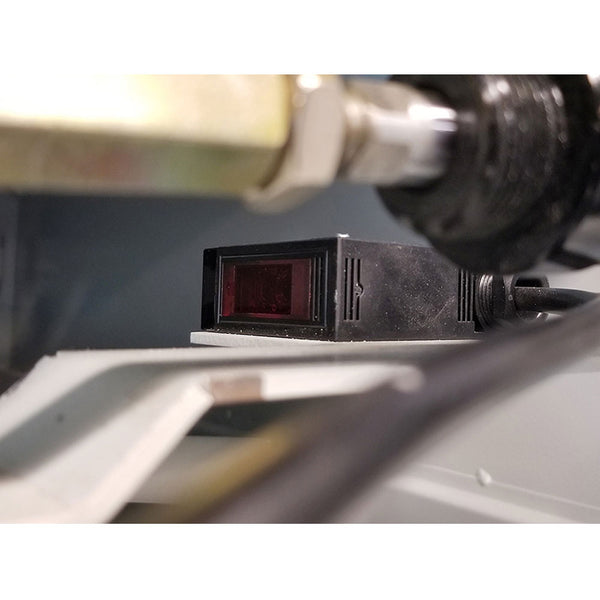

Electronic send & receive sensor precisely detects the sanding belt for the most reliable belt tracking. The machine is also equipped with belt overrun limit switches for added safety. Variable feed speed allows the operator to choose the correct sanding speed for various sanding applications, belt grits, wood species, and desired results.

Outfitted with powerful 20HP 15HP sanding motors and a pneumatic disc braking system that facilitates faster belt changes with added machine safety. Equipped with an over-height lever gate that will automatically shut off the machine should a workpiece too thick be sent through for sanding. Also equipped with a front safety bar, emergency stop buttons on front and rear of the machine, and safety switches on all door panels.

If you need a quote, we would be happy to provide one. Call 260-637-0054 or email sales@oaktreesupplies.com

Note: Cannot ship to Indiana, Ohio, Pennsylvania or California.

Features

- Dual sanding heads increase efficiency by reducing the number of passes

- Rubber contact drum for calibration sanding

- Combination sanding unit with 5” rubber contact drum and 2” wide adjustable sanding platen for a wide range of sanding applications

- Adjustable platen produces superior sanding results with finer sandpaper grits

- Solid cast iron sanding heads and mounting base for superior vibration damping resulting in an optimum sanding result

- Equipped with automatic conveyor belt tracking to ensure the conveyor belt is centered and does not track off to one side, which could damage the belt

- Accurate digital thickness control with both Inch & Metric settings allows the operator to key in the desired thickness and the table will automatically move into position

- Table is raised and lowered by four industrial ball screws ensuring perfect flatness and added durability

- Two sanding heads

- First Head: Rubber contact drum with 7” diameter drum

- Second Head: Combination head with 5” diameter drum and 2” wide platen

- Electronic belt tracking for optimum belt life and sanding results

- Ammeter for load monitoring to ensure the proper amount of material is being removed according to the selected grit

- Disc brake on main motor allows for faster belt changes

- Pneumatic belt tensioning with quick-release outboard support to facilitate fast belt changes

- Double infeed and outfeed pressure rolls for superior part hold down

- Four table-raising jack screws

- Material over-height limit switch

- Hour meter records the actual running time of the machine which can be used to provide timely maintenance for the machine

- Interlocks located on all access doors

Specs

Abrasive belt size: 37” x 60” (940 x 1,524 mm)

Main motor (First Head): 20hp

Main motor (Second Head): 15hp

Feed motor: 2hp

Table rise/fall motor: 1/2hp

Max. width stock: 36” (914 mm)

Min. part length: 13"

Min. thickness opening: 5"

Feed speed: variable: 13 to 52 FPM

Passline height: 33”- 38” (838 – 965 mm)

Infeed table: 11-1/2” (279- 12.7 mm)

Dust outlet: 4 @ 4” (100 mm)

Compressed air usage: 2 CFM @ 90 PSI

New weight: 3,300 lbs.

Machine dimensions: 74” x 64” x 70” (1,879 x 1,625 x 1,778 mm)

Shipping weight: 5,390 lbs.

Shipping dimensions: 78” x 67” x 76” (1,981 x 1,701 x 1,930 mm)

*Shipping

Please note: Items being shipped to extremely remote areas or areas with limited delivery access (such as islands only accessible by ferry) may incur additional shipping or freight fees. If your order requires any additional fees other than what is already included in the price, you will be contacted before those fees are applied and before your item ships. This is rare and will not apply to most orders.