Cantek GT400BRD 16" X 6.7" Double Surfacer Planer

- Price

- $ 26,880

Have questions? Give us a call at 260-637-0054.

Our Easy Purchase Guarantee:

- No hassle pricing — always sold at the manufacturers lowest price!

- Freight included in price.*

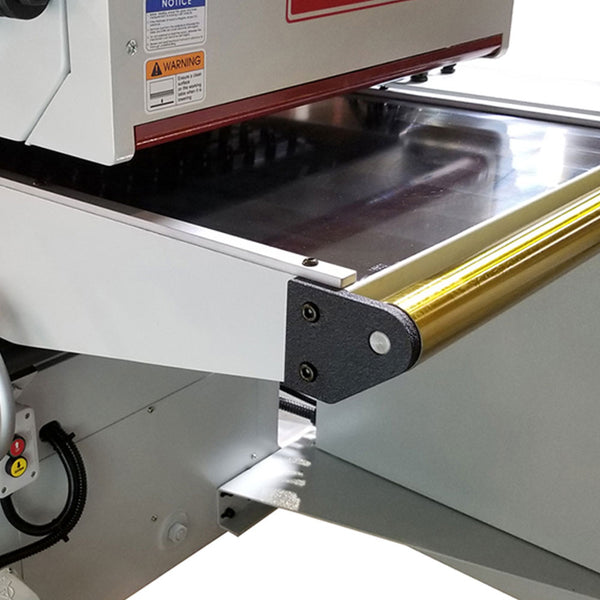

The Cantek GT400BRD 16″ Double Surface Planer has a robust cast-iron body for industrial planning day in and day out. The spiral insert knife cutterheads produce a smooth planed finish with maximum stock removal. The material is passed over the bottom head with a spring-loaded pin feed system allowing it to act like a jointer to flatten the board prior to being planed to an accurate thickness with the top head.

If you need a quote, we would be happy to provide one. Call 260-637-0054 or email sales@oaktreesupplies.com

Note: Cannot ship to Pennsylvania or California.

Features

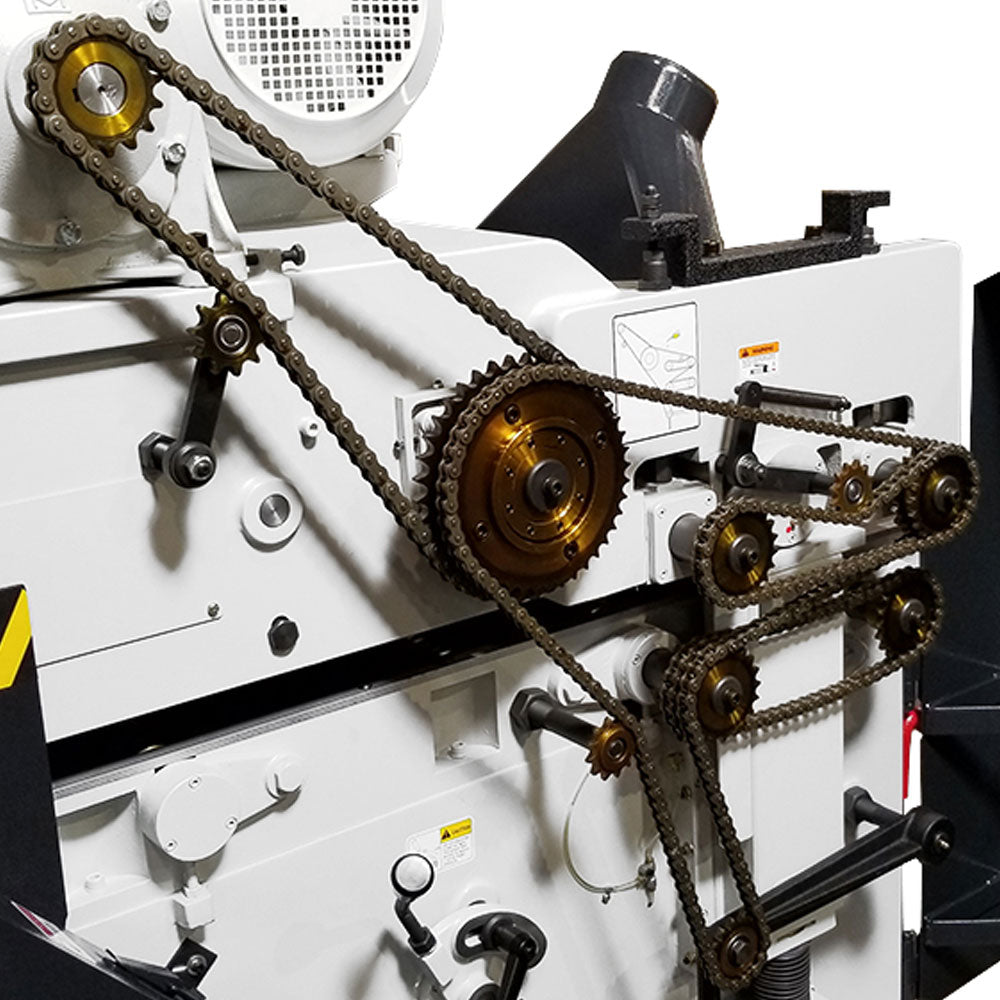

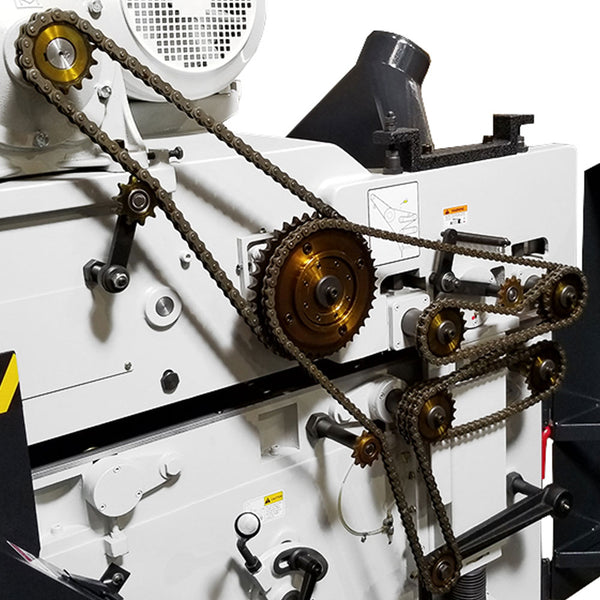

- Spring loaded conveyor pin system ensures material is passed over the bottom cutterhead to result in a flat and uniform board prior to planning to thickness on the top head

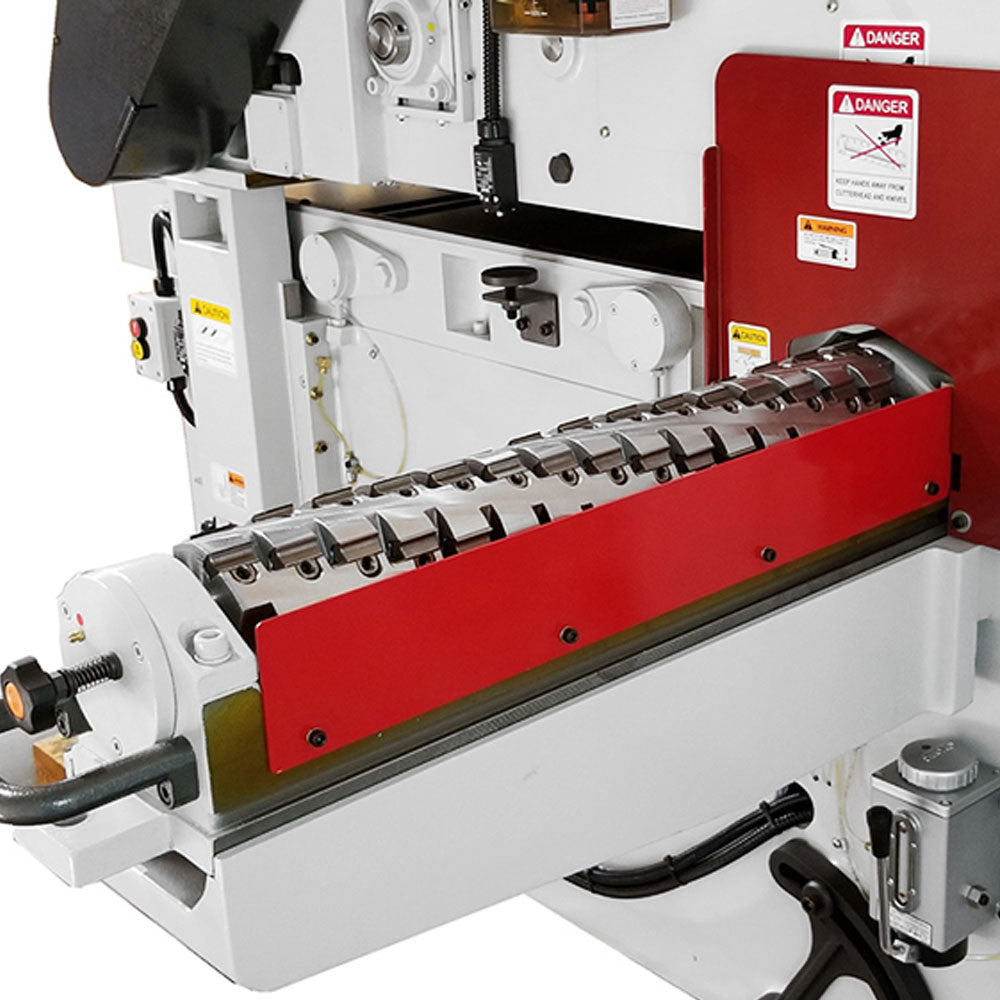

- Spiral insert knife cutter heads with two-sided solid carbide knives produce a smooth finish with increased stock removal capacity and extremely quiet operation

- Heavy-duty cast-iron machine body and table for vibration-free cutting

- Digital electronic thickness adjustment in INCH and MM (Inch = 0.001” / mm = 0.01mm resolution) for precise thickness control

- 16″ wide x 6.7″ thick planning capacity

- Cutterheads are spiral insert type with six (6) rows of carbide inserts

- (2) driven and (1) idle bed roll for superior feeding of even difficult material

- Swiveling control panel for more ergonomic access to machine controls

- Inverter variable speed control with feed speeds from 26 to 80 FPM

- Easy to access external handwheel adjustment of infeed bed

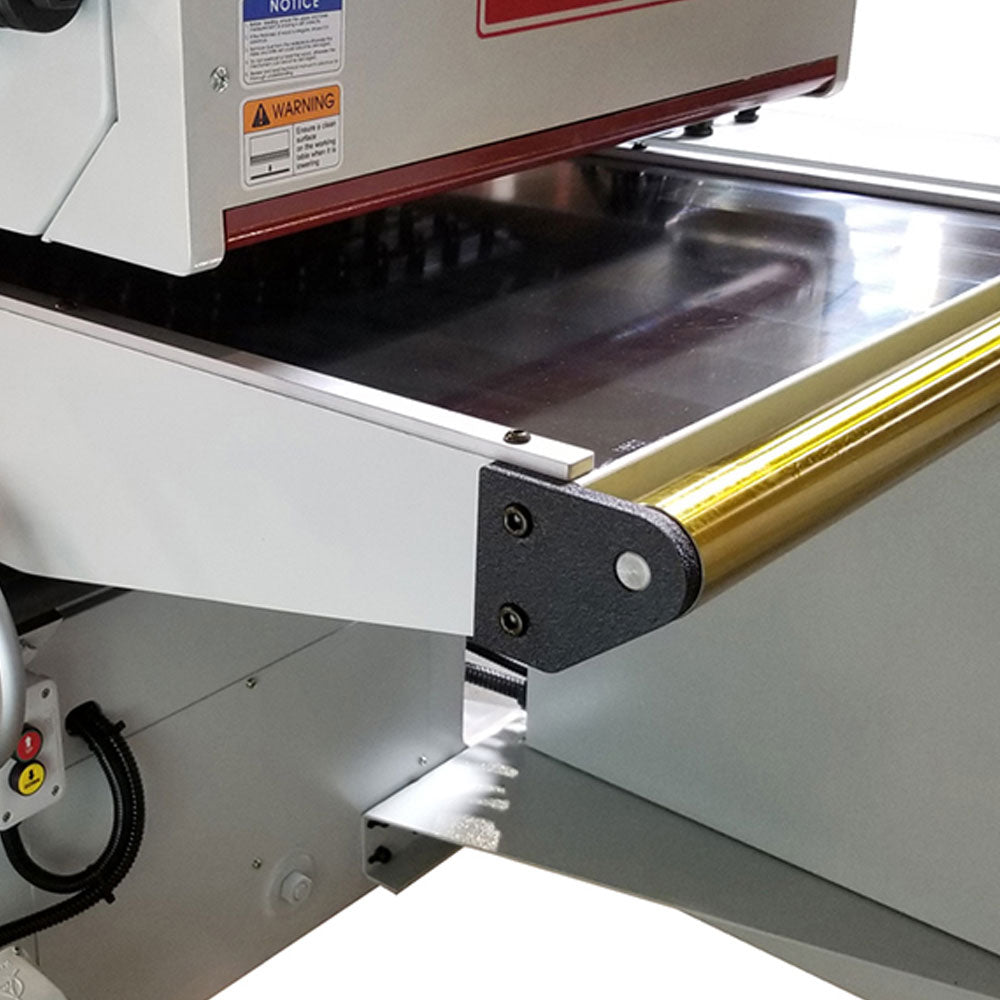

- Hard chromed worktable for high wear resistance

- Auto lubrication to conveyor chain, central lubrication for dovetail elevation guideways

- Section chipbreaker and sectional feed roller before top cutterhead

- Rubber outfeed top roller to prevent chip marking

- Over-thickness safety shut-off bar across infeed.

- Ammeter for each motor on control panel to monitor motor load

Specs

Maximum working width: 16″ (405 mm)

Maximum working thickness: 6.7″ (170 mm)

Minimum workpiece length: 10″ (250 mm)

Minimum working thickness: 0.315″ (8 mm)

Bottom jointing head motor: 10hp

Top planing head motor: 15hp

Feed motor: 2hp

Table elevation motor: 1/2hp

Cutterhead diameter: 4″ (101 mm)

Knife information: 30 mm x 12 mm x 1.5 mm (60 knives / head)

Cutterhead speed: 5,000 RPM

Feed speed (variable): 23~65 FPM (8~24 m/min)

Dust collection: 2 @ 5″ diameter (2 @ 125mm)

Table size: 19″ x 86″ (482 x 2,185mm)

Machine dimensions (L x W x H): 86.6″ x 35.43″ x 66.93″

Net weight: 4,180 lbs.

Packaging dimensions: 90.5″ x 37.4″ x 72.83″

Gross weight: 4,620 lbs.

*Shipping

Please note: Items being shipped to extremely remote areas or areas with limited delivery access (such as islands only accessible by ferry) may incur additional shipping or freight fees. If your order requires any additional fees other than what is already included in the price, you will be contacted before those fees are applied and before your item ships. This is rare and will not apply to most orders.