Osmo Polyx-Oil Original - 0.75L

- Price

- $ 53.99

Have questions? Give us a call at 260-637-0054.

Osmo Polyx-Oil is a general-purpose Hardwax-Oil wood finish that uniquely combines the advantages of natural oils and waxes in one product. It is stain-resistant, water repellent, and abrasion-resistant and results in a surface that is pleasant to the touch. In comparison to conventional finishes, the use of plant ingredients creates a more even color and more harmonious appearance.

This finish is derived from natural vegetable oils and waxes. Resistant to water, dirt, beer, wine, cola and saliva, Osmo Polyx-Oil is microporous and molecularly bonds with the wood, meaning it does not crack, flake, peel or blister.

The advanced formula of Polyx-Oil has been specially engineered in Germany to be the first Hardwax-Oil available on the North American market that can be easily applied with a brush or roller, with no buffing necessary! Can be spot-repaired and/or restored/renewed with no sanding required, therefore wood never needs complete sanding and refinishing again.

Also available in 0.125L and 2.5L sizes. For an untreated appearance, use Osmo Polyx-Oil Raw Matte.

Don't forget your brushes and pads!

Note: Oils enhance the natural tone of wood (permanent wet effect). Applying the product too generously and insufficient ventilation lead to delays in drying.

Features

- Easy to apply – used by both professionals and homeowners

- Extremely durable and hardwearing

- Can be spot-repaired and refreshed with no sanding required

- Microporous finish which does not crack, peel or flake

- Resistant to water and dirt as well as juice, tea, cola, wine, beer, coffee

- Enhances the wood’s natural character

- Saliva-resistant and sweatproof, suitable for children’s toys

Specs

Coverage rate: 194 sq. ft.

Number of coats: 2 coats

Application temp.: 41°F - 95°F (5°C to 35°C)

Approx. drying time: 8-10 hours*

Full cure time: 2-3 weeks

*Lower temperatures and/or higher air humidity can increase the drying time. Ventilate well while drying.

Directions (Pad)

- Stir the Polyx-Oil well and pour into tray

- Work the product into the wood thinly and evenly in figure 8 or circular motions using the fleece applicator pad

- Be sure to thinly and evenly coat the surface and leave on the surface for approx. 5 minutes

- Allow approx. 8-10 hours drying time. Allow for good ventilation whilst drying

- Apply second coat following previous steps.

Directions (Brush/Roller)

First Coat: Apply one thin coat with an Osmo Floor Brush or Osmo Floor Roller. Our rollers have a 4.5mm nap.

- Stir the Polyx-Oil well and prior to use

- Brush or roll the product thinly and evenly onto the floor

- Do not remove excess product, this will absorb into the wood surface over the drying period

- Allow 8-10 hours drying time prior to proceeding to second coat

- Brush or roll the second coat thinly and evenly onto the floor

- Allow approximately 5-10 minutes for product to penetrate surface

- Allow 8-10 hours drying time. Allow for good ventilation whilst drying

Third Coat: Usually a third coat is not required, however highly absorbent or dry timbers may appear to require a third coat.

Please consult OSMO technical support at 1-844-OSMOCAN prior to carrying out a third coat

Tinting: Osmo Wood Wax Finish can also be used to lightly tint Polyx-Oil 3054 up to a ratio of 10:1. Do not exceed a ratio of 10 parts Polyx-Oil 3054 to 1 part Wood Wax Finish.

Cure Period: Osmo Hardwax-Oil(s) like all floor finishes have a cure period. We recommend allowing 2 weeks for the surface to fully cure and harden prior to damp-mopping or placing rugs/mats on the surface.

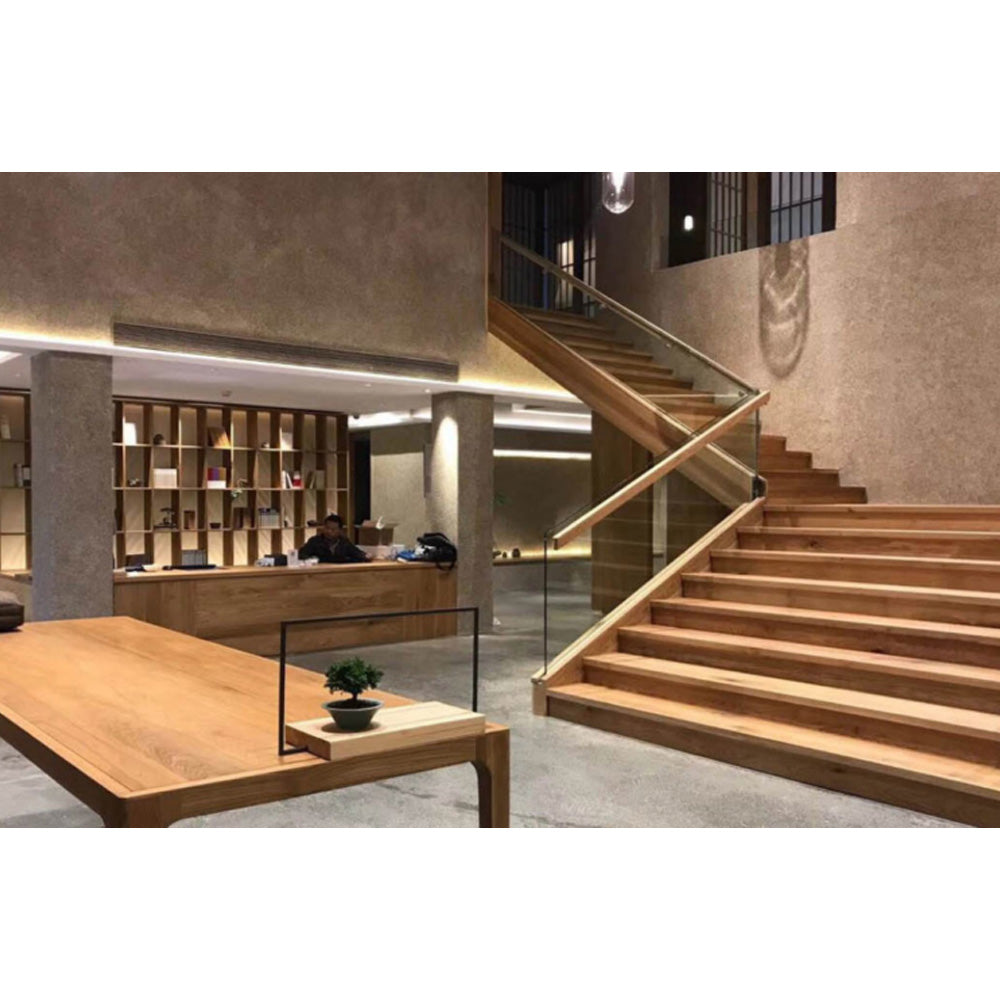

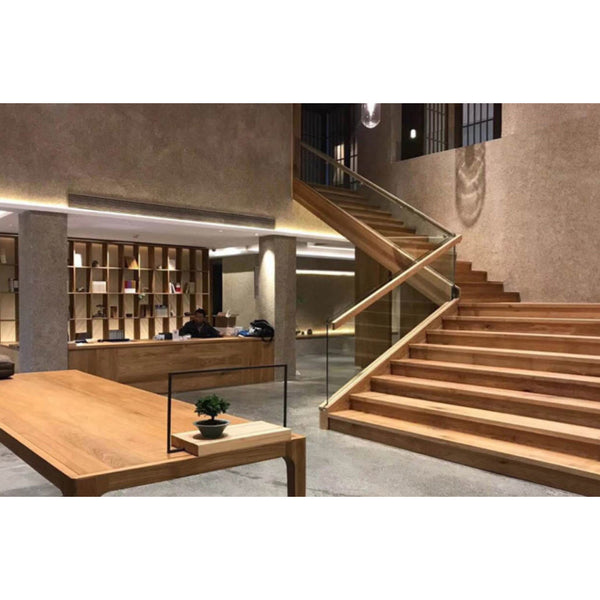

Video

Project two, I finished a kitchen table, ash with walnut accents, using the oil for cutting boards. It wasn't quite glossy enough so the second coat was received the gloss oil. Overall these oils are expensive but cover a decent amount of area. My first project, I finished a live edge white oak table. I didn't want the amber effect which most oils produce. The natural oil lured me in with the claim of no amber (adding a hint of white in the oil). I absolutely love the results. I applied the oils with a polishing pad via my 6" orbital sander. OMG this stuff is so forgiving and easy to use I'll never go back to Poly. I just wish it was more affordable and available.

I used this product on a coffee table and two end table made of ash. I am very impressed with both the ease of application and the finished look of the tables. Will be my go to finish from now on.